Method for detecting cigarette smoke aerosol particle size distribution

A technology for cigarette smoke and particle size distribution, which is applied in the field of analysis and detection, and can solve problems that affect the accuracy of smoke aerosol particle size analysis and detection, unstable flow rate, and difficult cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

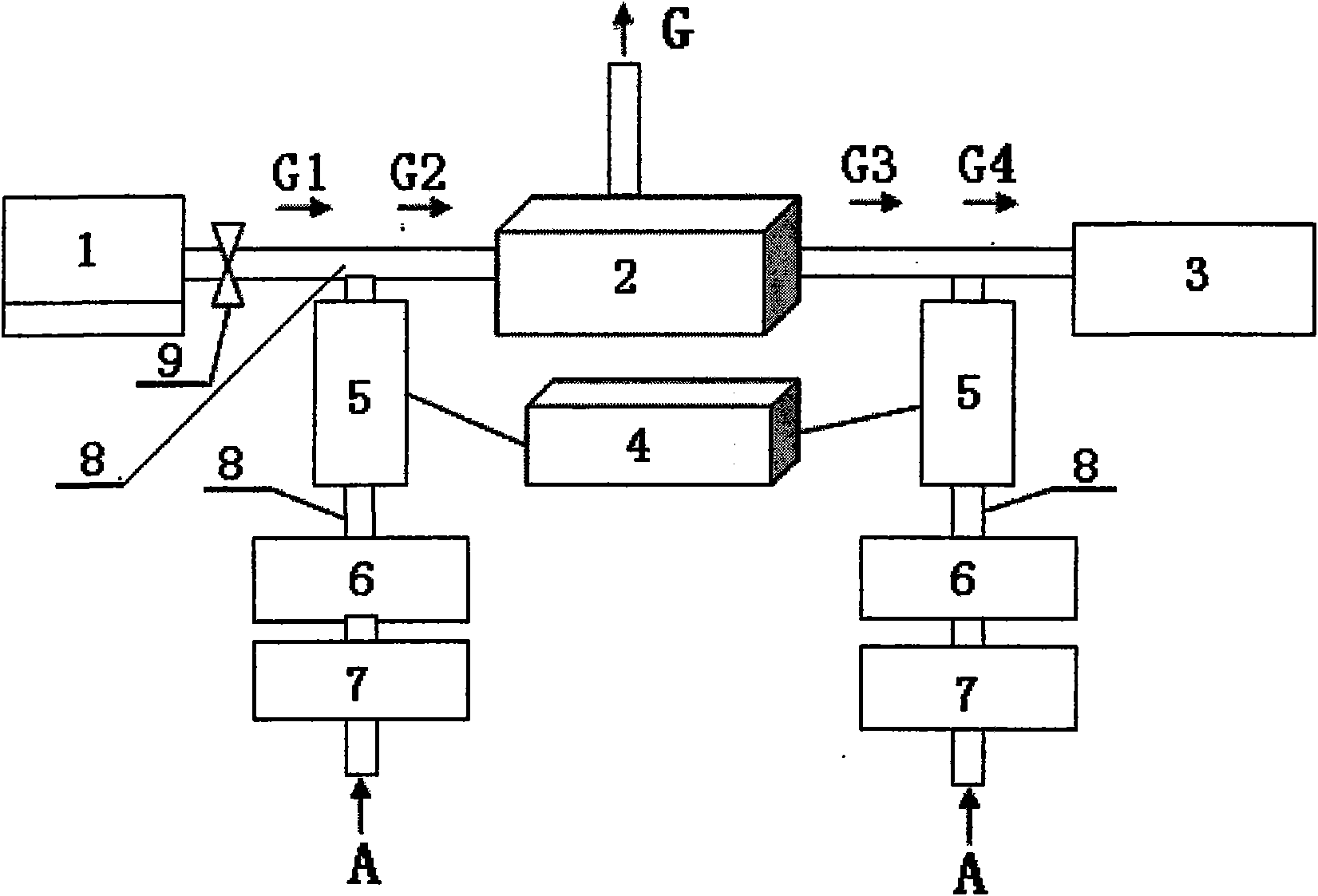

[0012] Such as figure 1 Shown, the present invention comprises the following steps in turn:

[0013] A. The composition of the measuring device, which is sequentially connected to the metal pipe 8 of the smoking machine 1, the temperature regulator 4, the heater 5, the electronic flow meter 6 and the filter 7 to form a first-stage dilution device; it is composed of a diluter 2 and an exhaust gas discharge port G A second-stage dilution device is installed; the metal 8 connected to the diluter 2 and the aerosol particle size spectrometer 3, the temperature regulator 4, the heater 5, the electronic flow meter 6, and the filter 7 constitute the third-stage dilution device;

[0014] B. Temperature adjustment and dilution. The flue gas is diluted by the first-stage dilution device and heated through the metal pipe 8. The electronic flowmeter 6 controls the dilution ratio so that the temperature of the incoming clean air is consistent with the temperature of the fresh flue gas flow;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com