Self-cleaning 3D digital printer smooth in feeding and convenient for raw material recovery

A printer and self-cleaning technology, applied in the direction of processing and recycling, 3D object support structure, process efficiency improvement, etc., can solve the problems of reducing air flow velocity, increasing cleaning equipment, increasing energy consumption, etc., to maintain smooth air flow and ensure cutting Unobstructed and anti-accumulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

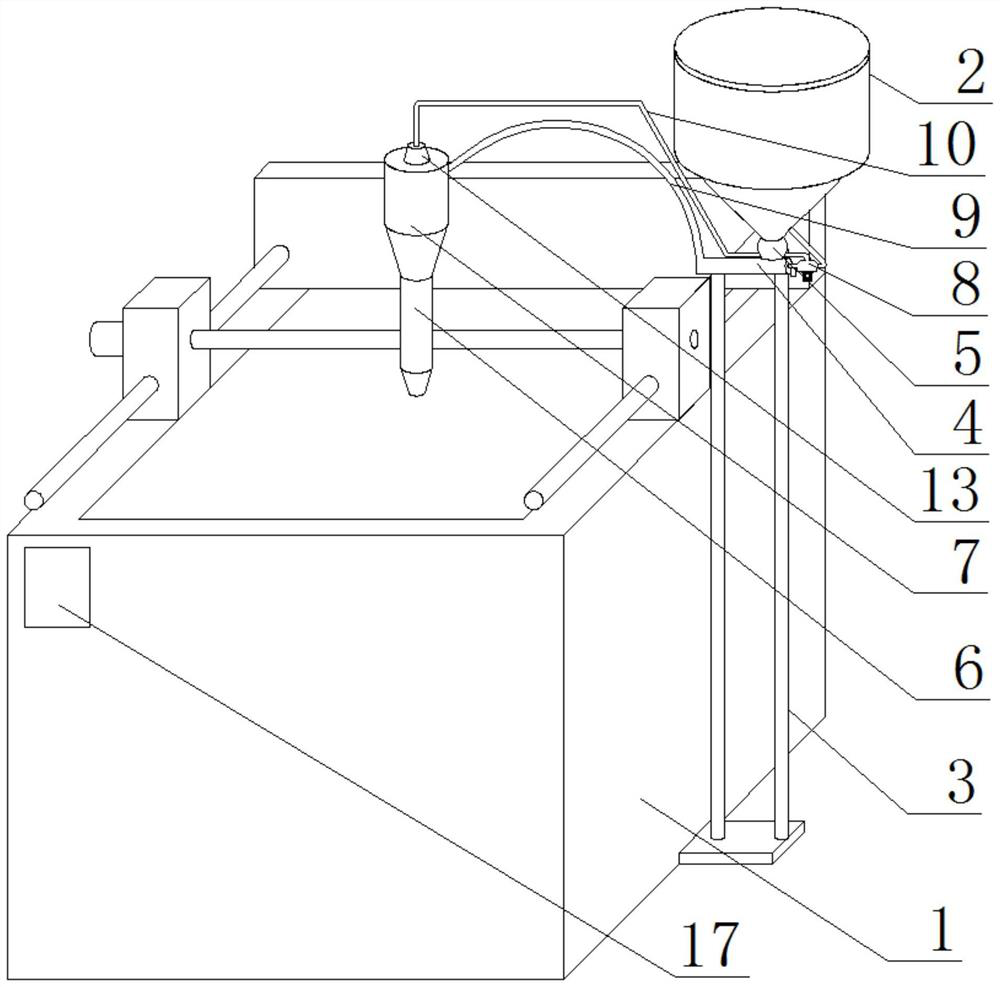

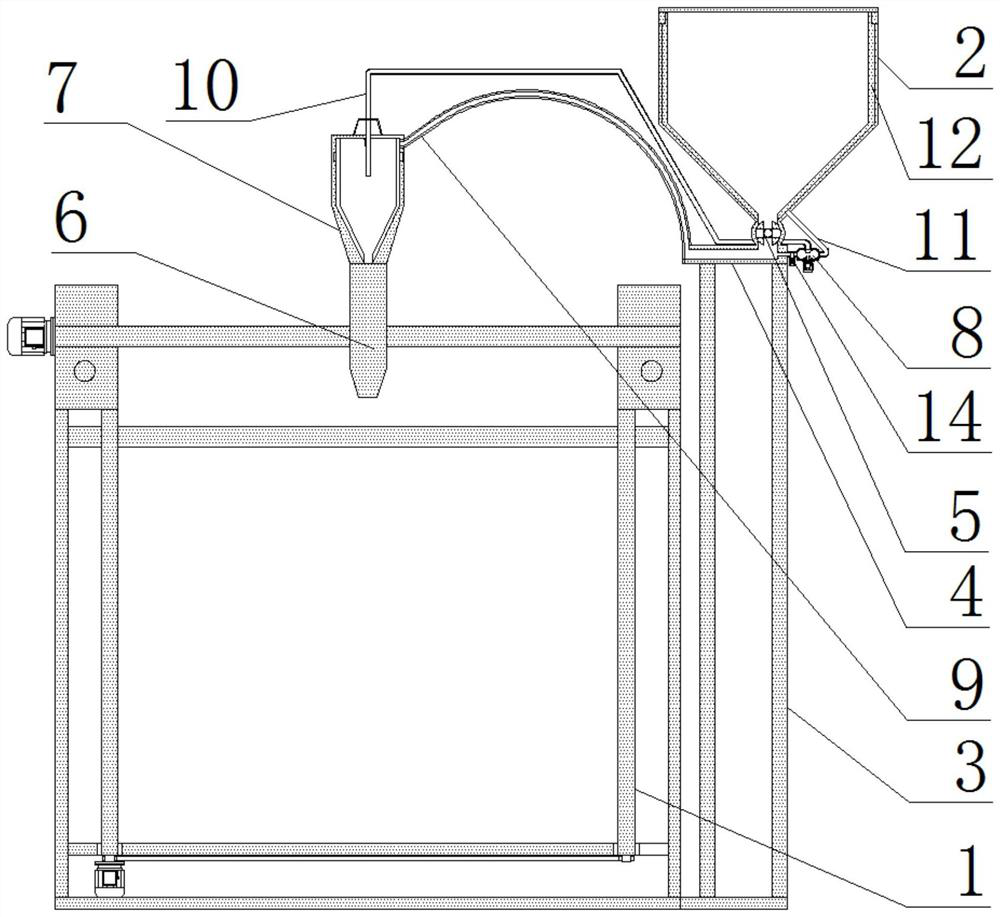

[0026] As a preferred embodiment of the present invention, the smart touch panel 17 is connected with the main body 1 of the 3D digital printer, the printing head 6 , the air pump 8 , the feeding valve 5 and the solenoid valve 14 through wires.

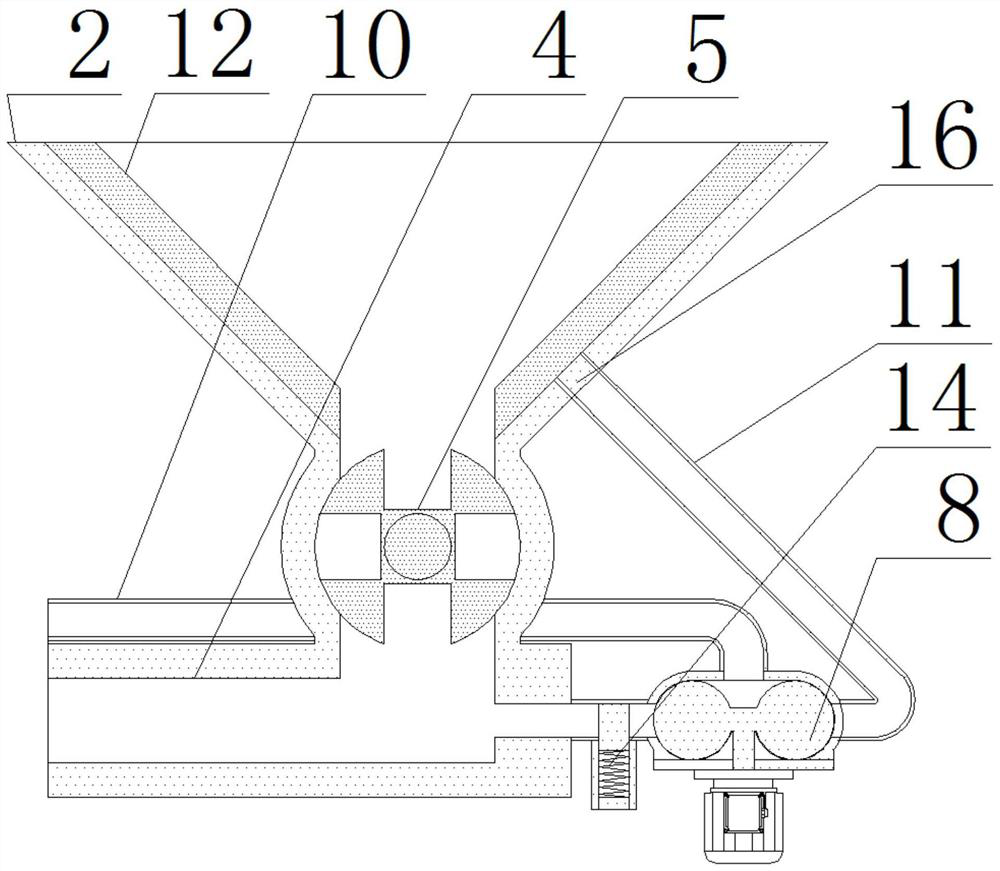

[0027] As a preferred embodiment of the present invention, the top of the horizontal pipe 4 communicates with the hopper 2 through the feeding valve 5, and one end of the horizontal pipe 4 communicates with the air pump 8 through the electromagnetic valve 14, and the feeding valve 5 will The powder raw material in the hopper 2 falls into the horizontal pipe 4 .

[0028]As a preferred embodiment of the present invention, the other end of the horizontal tube 4 communicates with the cone barrel 7 through a feed pipe 9, and one end of the feed pipe 9 passes through the cone barrel 7 and is attached to the inner wall of the cone barrel 7 , one end of the conduit 11 passes through the hopper 2 and sticks on the inner wall of the hopper 2, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com