Dispersion composition, cosmetic preparation for skin care, and method for producing dispersion composition

A manufacturing method and composition technology, applied in the field of dispersion composition, capable of solving the problems of stability, dispersibility, color, taste, and property deterioration of difficult carotenoid dispersion compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0156] (1) Production of water dispersion (i)-a, (i)-b

[0157] Each component described in the following Table 1 was dissolved while heating at 70° C. for 1 hour to obtain an aqueous composition.

[0158] And each component described in the following Table 2 was melt|dissolved for 1 hour, heating at 70 degreeC, and the oil phase composition was obtained.

[0159] 【Table 1】

[0160] Sucrose Stearate (HLB=16) 13g Decaclyceryl Monooleate (HLB=12) 25g glycerin 500g pure water 322g

[0161] Sucrose stearate: Riyotoshiyuga-ester S-1670 (HLB=16) manufactured by Mitsubishi Chemical Fuji Co., Ltd.

[0162] Decaclyceryl monooleate: NIKKOLD Decaglyn 1-O (HLB=12) manufactured by Nikko Chemicals Co., Ltd.

[0163] 【Table 2】

[0164] Haematococcus pluvialis extract (astaxanthin content 20% by weight) 40g mixed tocopherols 10g Lecithin (from soybeans) 90g

[0165] Haematococcus pluvialis extract: ASTOTS-S manufact...

Embodiment 2

[0208] (1) Production of water dispersion (iii)-a, (iii)-b

[0209] In the same manner as the aqueous dispersions (i)-a and (i)-b produced in Example 1, aqueous dispersions (iii)-a and (iii)-b were obtained.

[0210] (2) Production of aqueous compositions (iv)-a to (iv)-g

[0211] The components in the following Table 5 were mixed and dissolved at room temperature to obtain aqueous compositions (iv)-a to (iv)-g.

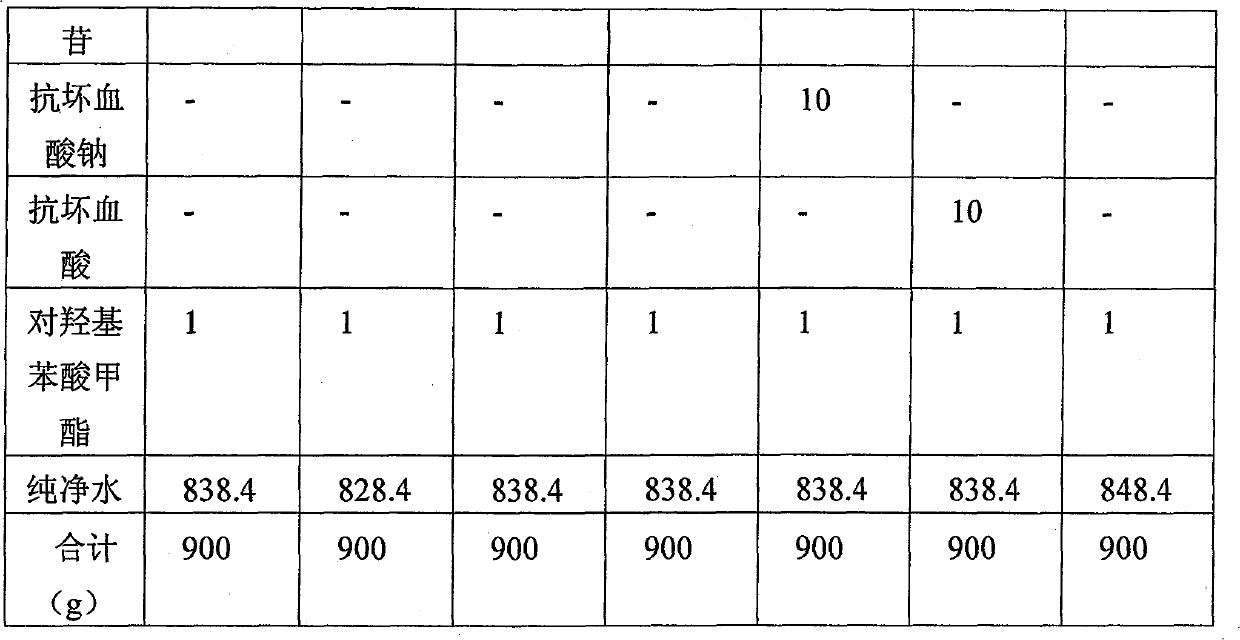

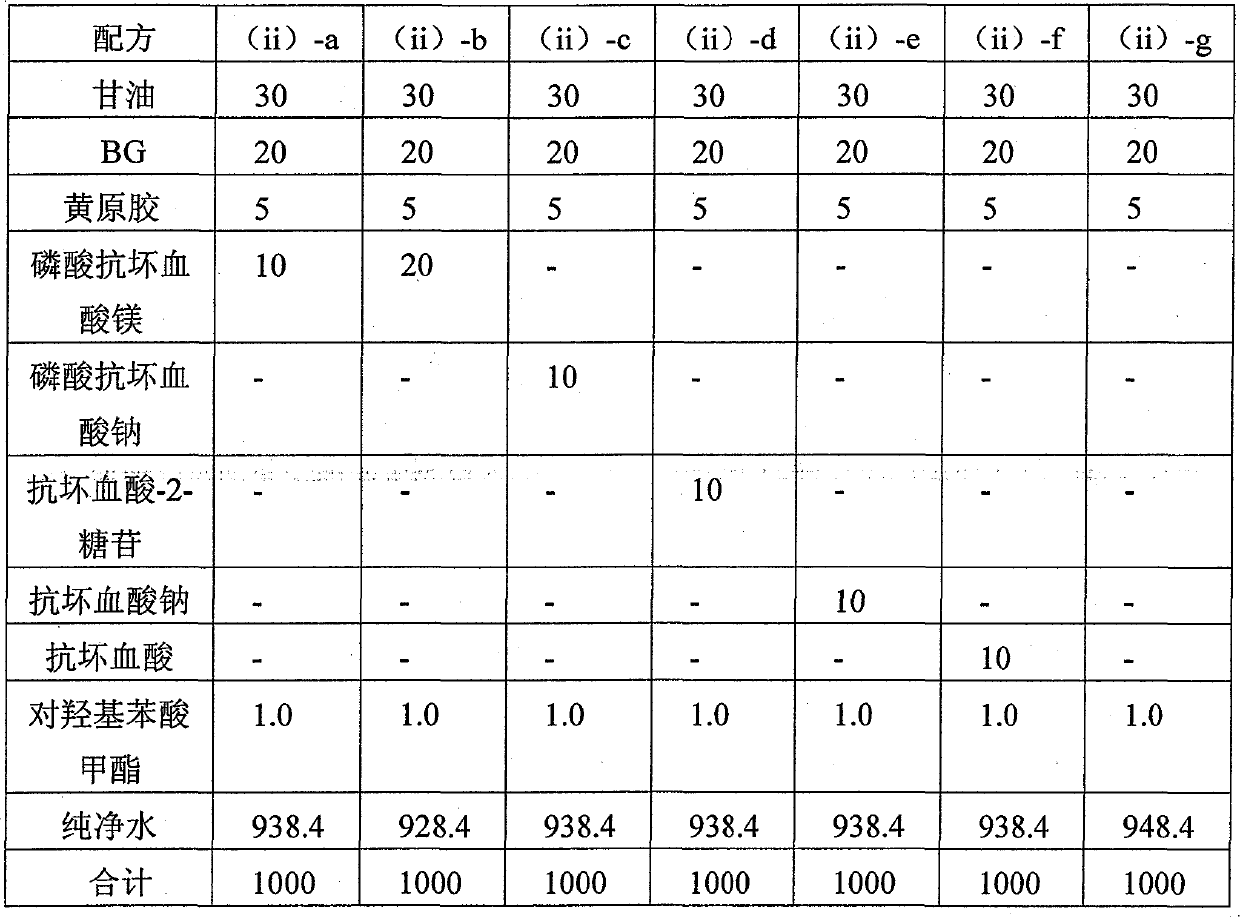

[0212] 【table 5】

[0213] formula (iv)-a (iv)-b (iv)-c (iv)-d (iv)-e (iv)-f (iv)-g glycerin 30 30 30 30 30 30 30 BG 20 20 20 20 20 20 20 xanthan gum 5 5 5 5 5 5 5 Magnesium Ascorbyl Phosphate 10 20 - - - - - Sodium ascorbate phosphate - - 10 - - - - Ascorbate-2-sugar - - - 10 - - -

[0214] [0213]

[0215] In 900g of the above aqueous composition (iv)-a, add 1% citric acid aqueo...

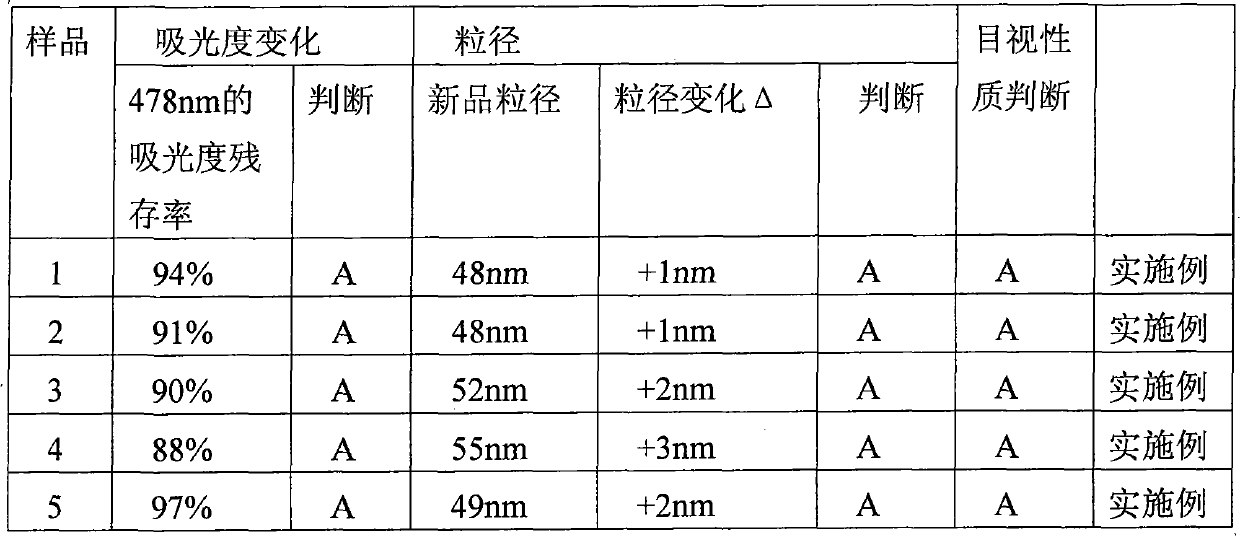

Embodiment 3~7

[0246] Instead of the aqueous composition (iv)-a, use (iv)-b, (iv)-c, (iv)-d, (iv)-e, (iv)-f respectively, as in Example 1, respectively Prepare dispersion liquid B-1~B-9 (embodiment 3), C-1~C-9 (embodiment 4), D-1~D-9 (embodiment 5), E-1~E-9 ( Example 6) and F-1 to F-9 (Example 7). These dispersions were evaluated in the same way as in Example 2. The results of Examples 3 to 7 are shown in Tables 7 to 11, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com