Thermal transfer printing method and thermal transfer printing system

A thermal transfer, transfer printing technology, applied in transfer printing, rotary printing machine, copying/marking method, etc., can solve the problems of loose bumps, low commonality of injection parts, increase inventory cost, etc. Great adhesion, avoiding process instability, and the effect of mass and stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

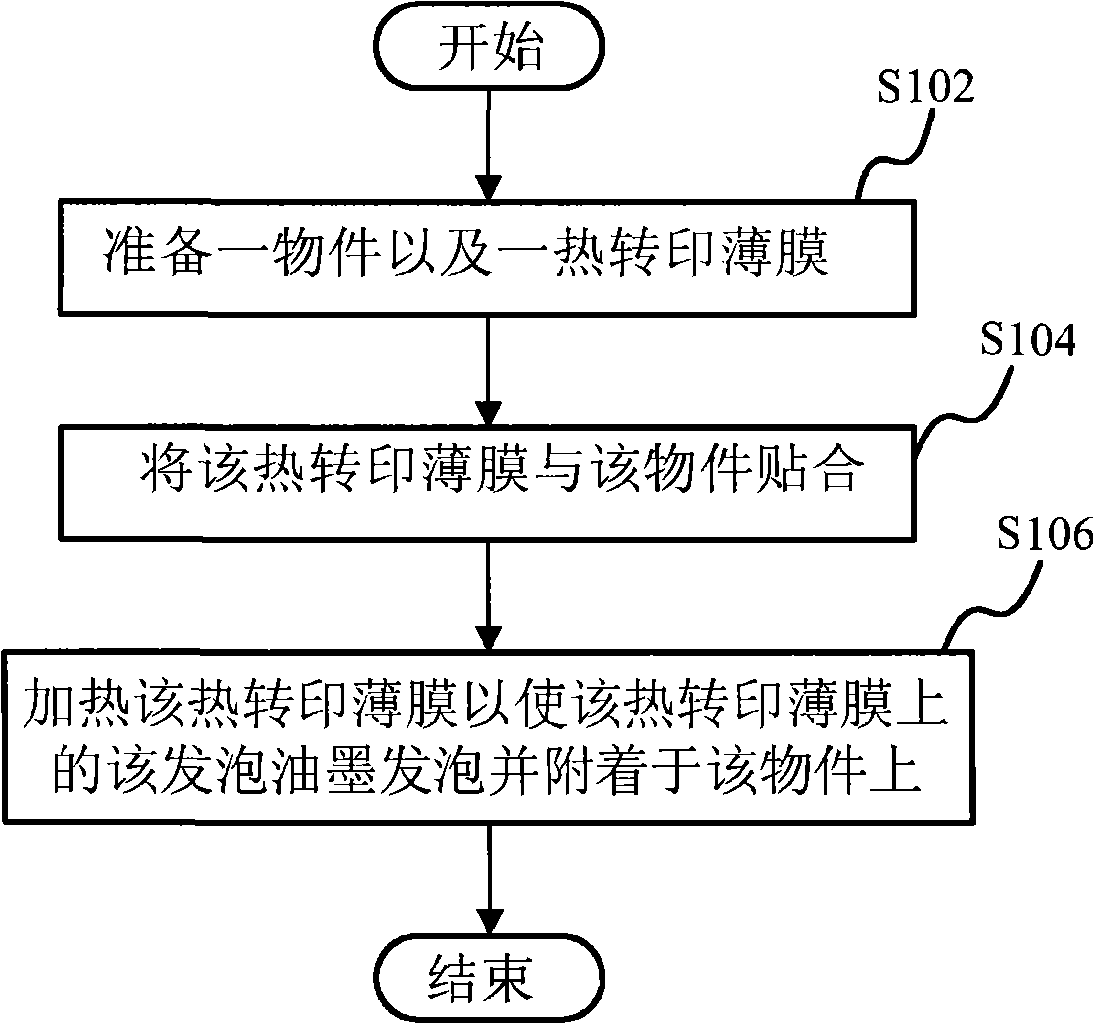

[0019] see figure 1 , which shows the basic flowchart of the thermal transfer method of the present invention. The heat transfer printing method of the present invention mainly includes: preparing an object and a heat transfer film, wherein the object includes a surface, and printing a foaming ink on the heat transfer film, as shown in step S102; The transfer film is attached to the object so that the foaming ink is on the surface, as shown in step S104; then the heat transfer film is heated to make the foam ink on the heat transfer film foam and adhere to Protrusions are formed on the surface of the object, as shown in step S106. Finally, the thermal transfer film can be peeled off again to obtain an object with bumps.

[0020] Applying thermal transfer printing technology, the present invention can break through the traditional situation of only using foaming ink on plane printing, and can transfer foaming ink on the surface of objects with three-dimensional features, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com