Cotton pad and production method thereof

A production method and technology of cotton pads, which are applied in the packaging of cosmetics, cosmetic powder containers, toiletry containers, etc., can solve the problems of unsatisfactory water absorption, complicated production process, high production cost, etc., so that it is not easy to loose and delaminate, The production process is simple and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

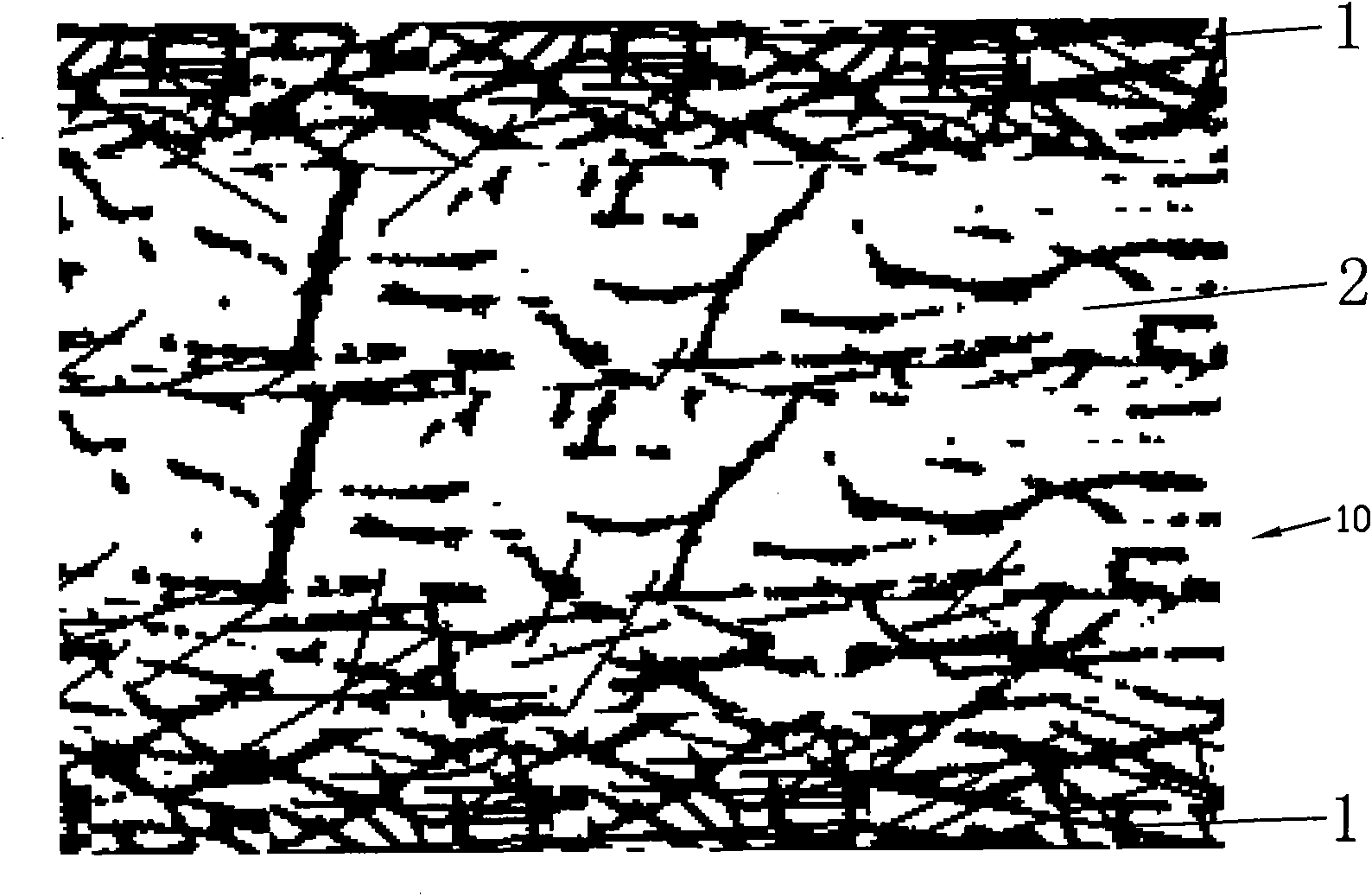

[0016] Such as figure 1 Shown is the integrally formed cosmetic cotton 10 through the spunlace process. The cosmetic cotton 10 is in the form of a sheet. The side part is the surface layer 1, and the middle part sandwiched between the surface layers on both sides is the cotton core 2, but in fact the cosmetic cotton 10 is integrated, and the surface layer 1 and the middle cotton core 2 are not strictly distinguished, but are passed through Cotton fibers are tangled together. The surface layer 1 of the cotton pad 10 is in the state of non-woven fabric, and the cotton core 2 of the cotton pad 10 is in the state of cotton. From the longitudinal section of the cotton pad 10, the density (or density) of the surface layer 1 of the cotton pad 10 is greater than that of the cotton pad 10. The density of the cotton core 2, and the density of the cosmetic cotton 10 gradually decreases from the surface layer 1 to the cotton core 2, that is, the cotton fibers become more and more dense f...

Embodiment approach 2

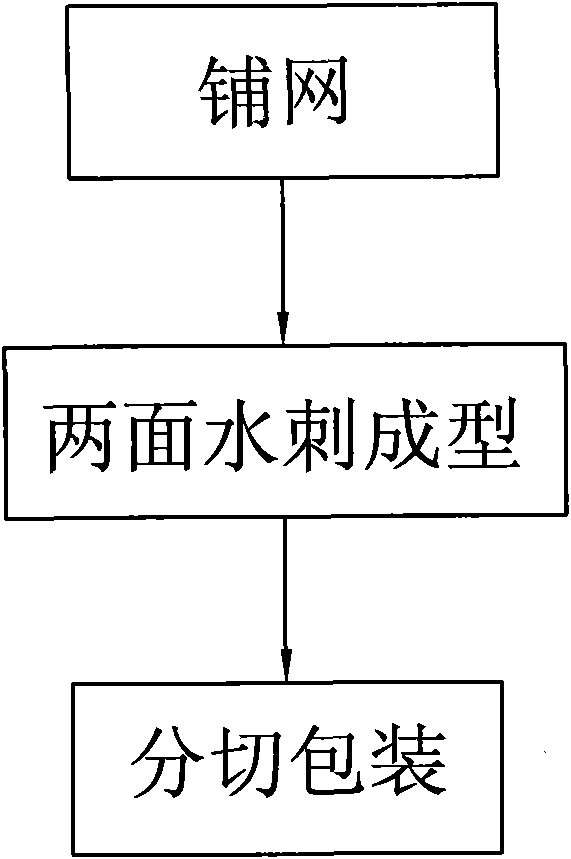

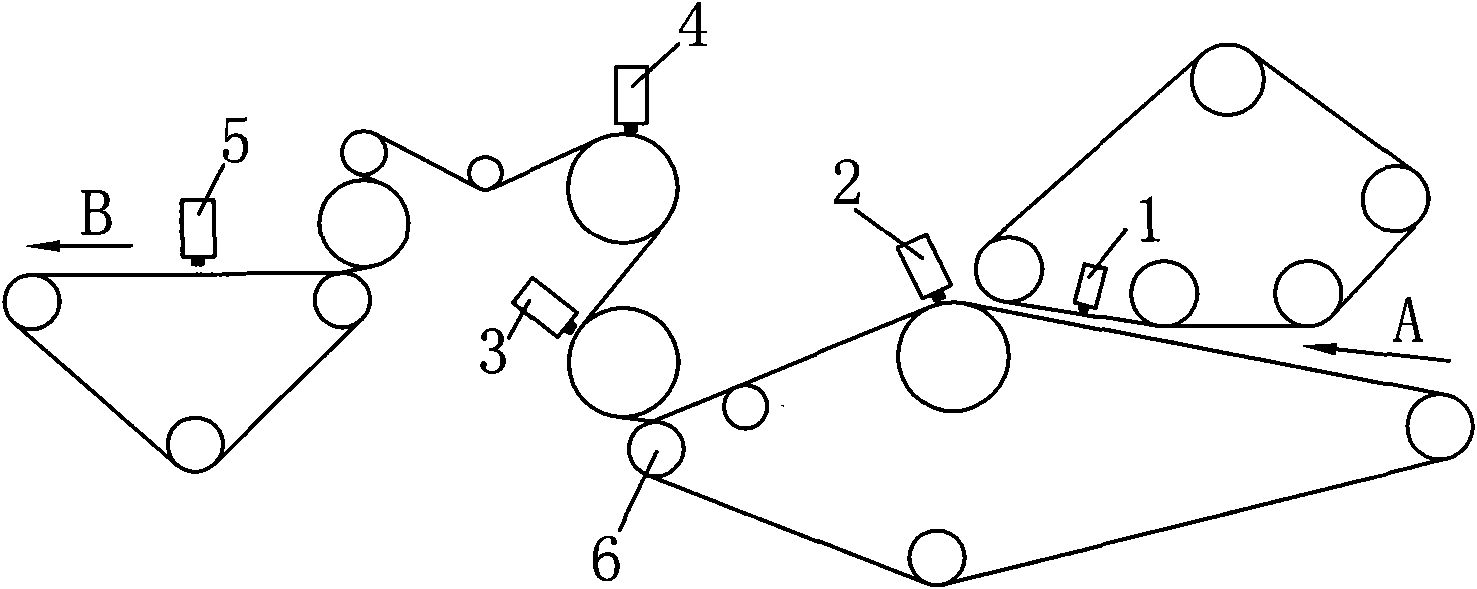

[0019] Such as figure 2 Shown, the production of the cosmetic cotton of above-mentioned embodiment adopts spunlace process, and its production method basically comprises the following steps:

[0020] Step 1: Laying the net, sending the cotton into the net lapper for cross-lapping, and laying a cotton net. The specification range of the laid cotton net is 60-160g / m 2 . At present, the spunlace process is used to produce spunlace non-woven fabrics. Spunlace non-woven fabrics need to be laid with thinner cotton nets, while cosmetic cotton is much thicker than non-woven fabrics, so the cotton nets required for cosmetic cotton are also Much thicker, for example 100g / m 2 . In this step, cross-lapping is used, so that the finished product has better tensile properties in both horizontal and vertical directions.

[0021] Step 2: Double-sided spunlace forming, using the spunlace process to spunlace the cotton net on both sides after laying the net. Spunlace uses fine high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com