Stress-relieving sampling method without damage of deeply buried rock

A stress relief and non-destructive sampling technology, applied in the direction of sampling devices, etc., can solve the problems of rock-related parameters, failure to represent rock strength, core sample damage, etc., and achieve the effect of ensuring mechanical properties, eliminating damage, and solving disturbance problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

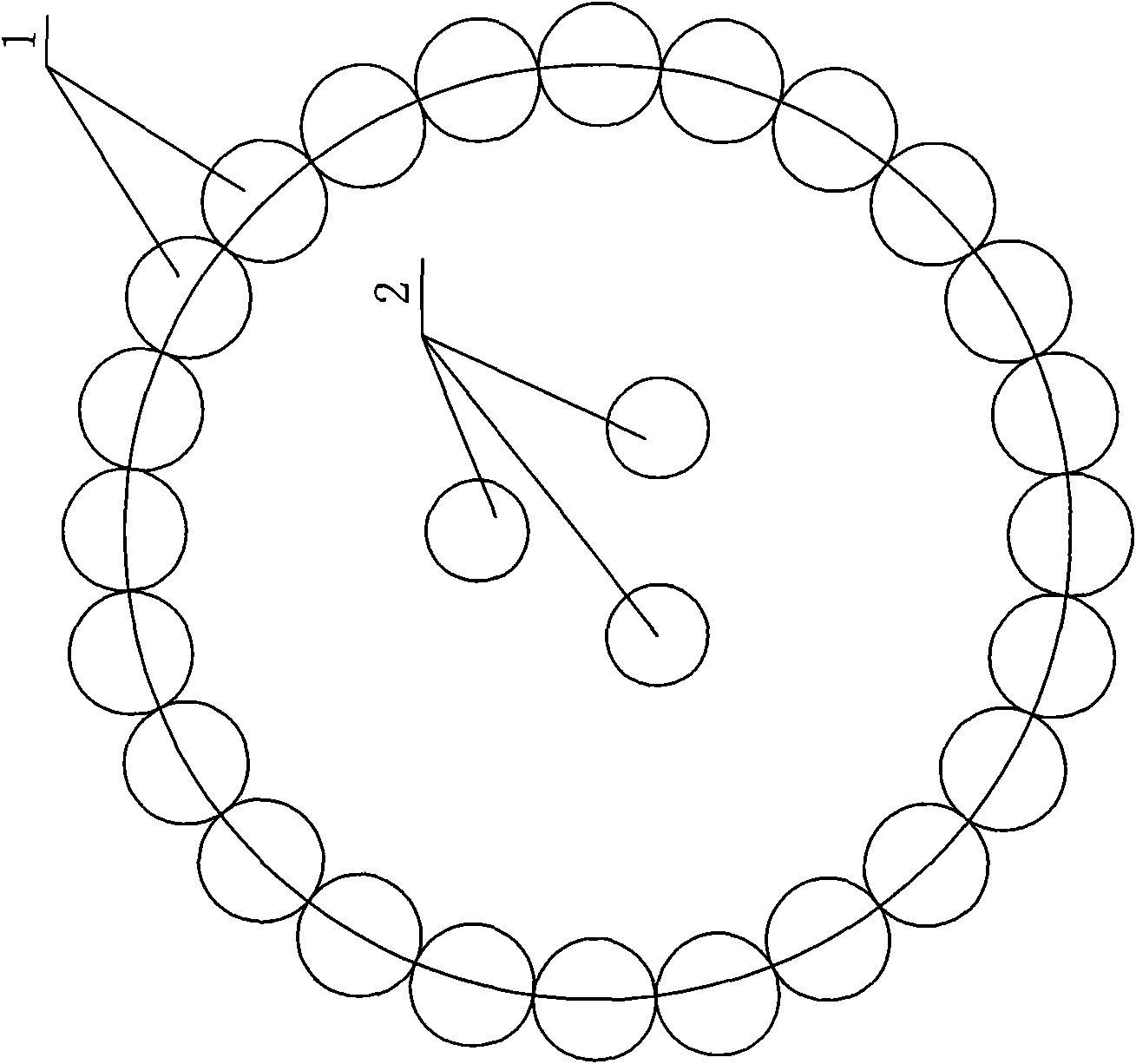

[0021] Embodiment 1: as figure 1 As shown, the specific steps of this embodiment include,

[0022] a. Select the sampling area on the bottom plate or side wall of the underground cavern. The sampling area should be no less than one-third of the cavern span or height from the cavern boundary. The boundary method here is that the sampling area is arranged in When the base plate is bounded by the side wall, when the sampling area is arranged on the side wall, the base plate and the top plate are bounded;

[0023] b. Drill a group of stress relief holes 1 along the boundary of the sampling area, the diameter of which is 91 mm, and the depth of the holes is one time of the span or height of the cavern, based on the principle of passing through the stress-disturbed zone of the cavern;

[0024] c. Drill at least one core hole 2 to obtain a rock core in the sampling area (within the diameter of the stress relief hole greater than or equal to one time). hole depth;

[0025] d. After...

Embodiment 2

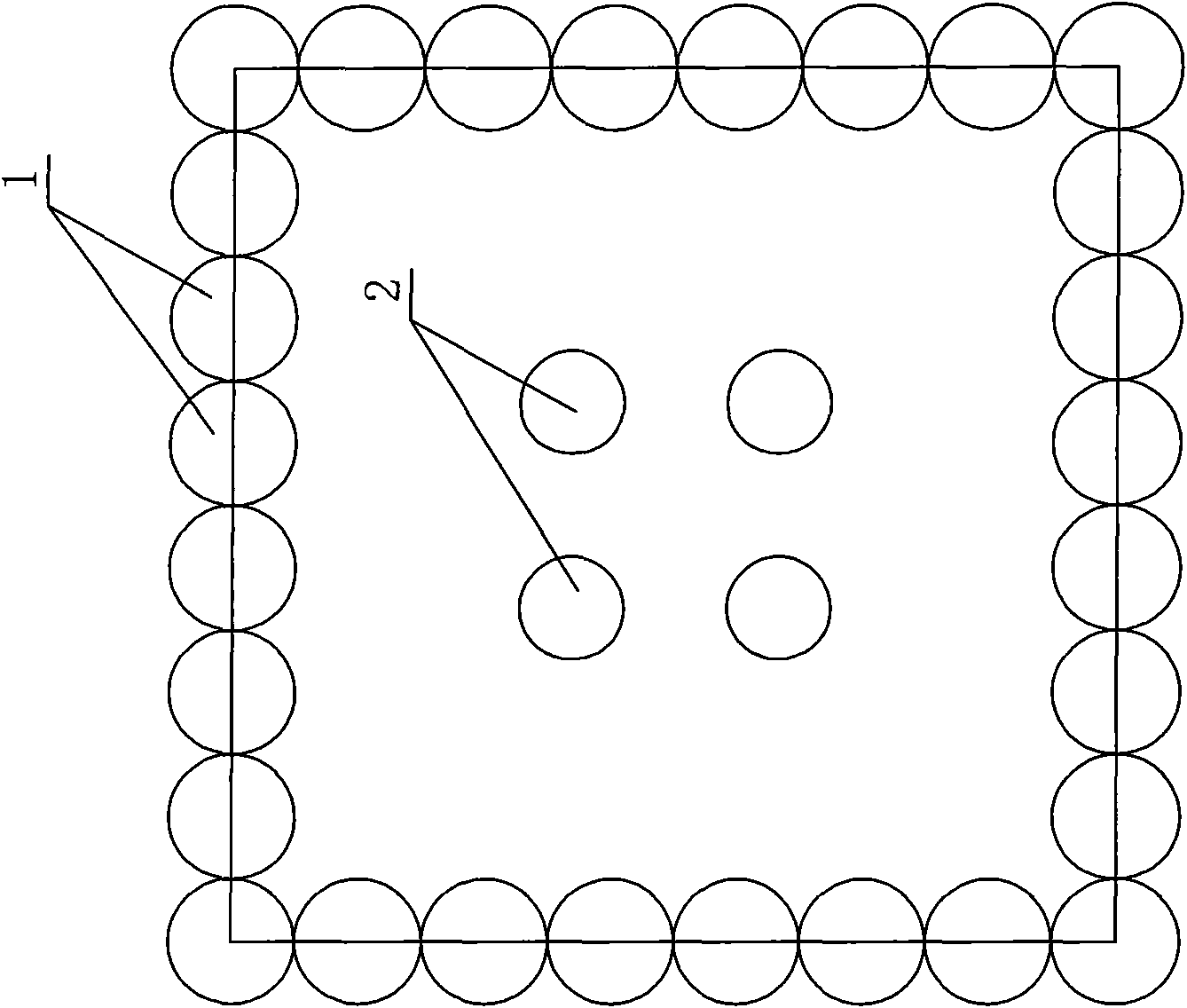

[0027] Embodiment 2: as figure 2 As shown, the specific steps of this embodiment include,

[0028] a. Select the sampling area on the bottom plate or side wall of the underground cavern. The sampling area should be no less than one-third of the cavern span or height from the cavern boundary. The boundary method here is that the sampling area is arranged in When the base plate is bounded by the side wall, when the sampling area is arranged on the side wall, the base plate and the top plate are bounded;

[0029] b. Drill a group of stress relief holes 1 along the boundary of the sampling area, the diameter of which is 91 mm, and the depth of the holes is one time of the span or height of the cavern, based on the principle of passing through the stress-disturbed zone of the cavern;

[0030] c. Drilling at least one core hole 2 in the sampling area to obtain a core, the diameter of the core hole 2 is 75mm, and the hole depth does not exceed the hole depth of the stress relief ho...

Embodiment 3

[0033] Embodiment 3: The construction steps of this embodiment are the same as those of Embodiments 1 and 2, except that the diameter of the stress relief hole 1 is 75mm, and the diameter of the corresponding coring hole 2 is 75mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com