Optical film and its production method, and glare-proof polarizer using same and display apparatus

A technology of optical film and manufacturing method, which is applied in the field of optical film, can solve problems such as deterioration of anti-glare properties, and achieve the effects of suppressing reflection, good clarity of transmitted images, and good visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

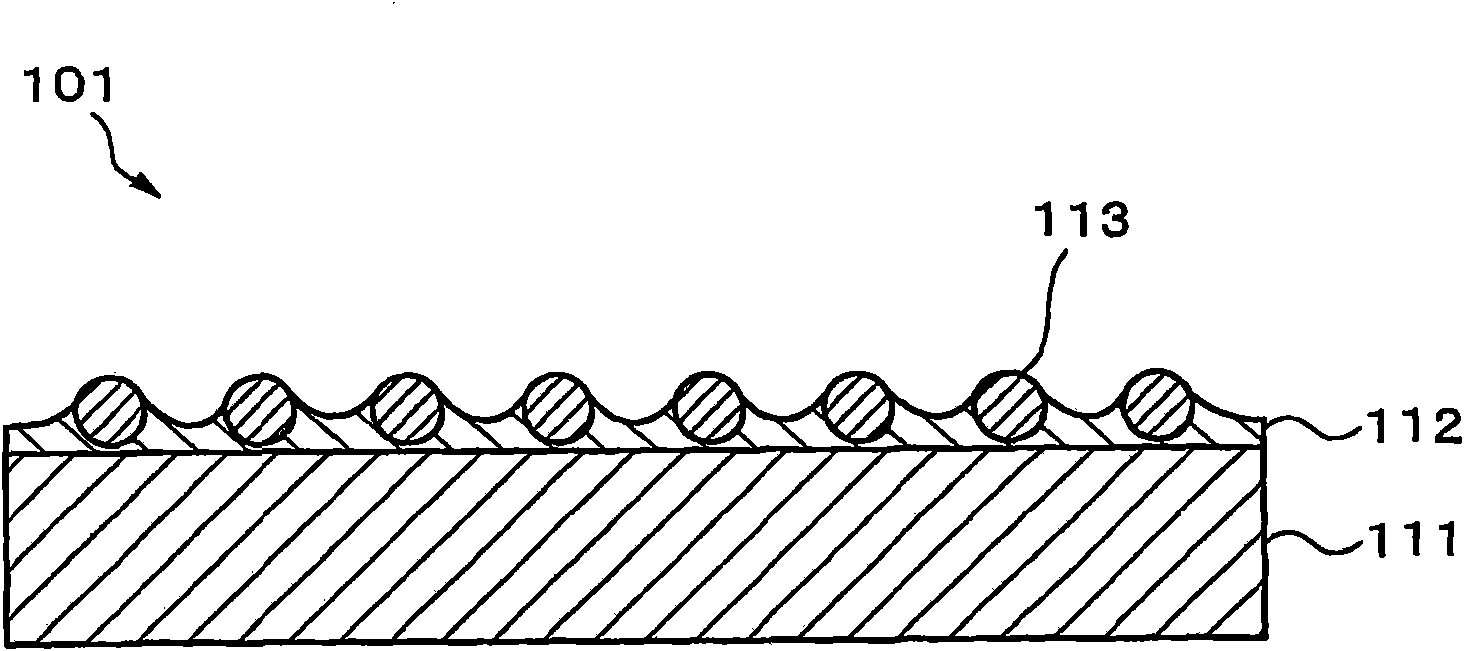

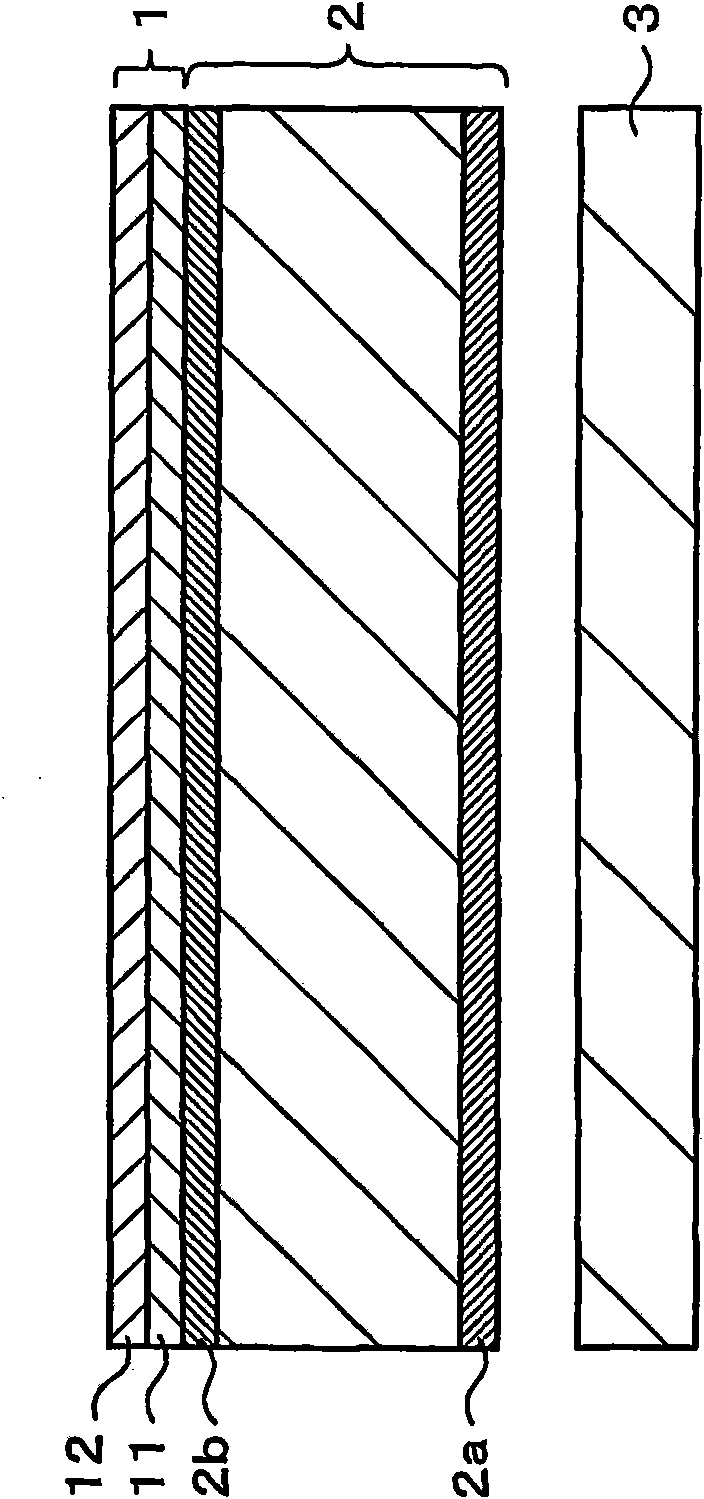

[0103] (1-1) Structure of liquid crystal display device

[0104] image 3 One example of the configuration of the liquid crystal display device according to the first embodiment of the present invention is shown. Such as image 3 As shown, the liquid crystal display device includes: a backlight 3 for emitting light; and a liquid crystal panel 2 for temporally and spatially adjusting the light emitted from the backlight 3 and displaying an image. Polarizers 2a and 2b are provided on both surfaces of the liquid crystal panel 2, respectively. The anti-glare film 1 is provided on the polarizing plate 2 b provided on the display surface side of the liquid crystal panel 2 .

[0105] As the backlight 3 , for example, a direct type backlight, an edge type (edge type) backlight, or a planar light source type backlight can be used. The backlight 3 includes, for example, a light source, a reflection plate, an optical film, and the like. As the light source, for example, CCFL (Cold...

no. 2 approach

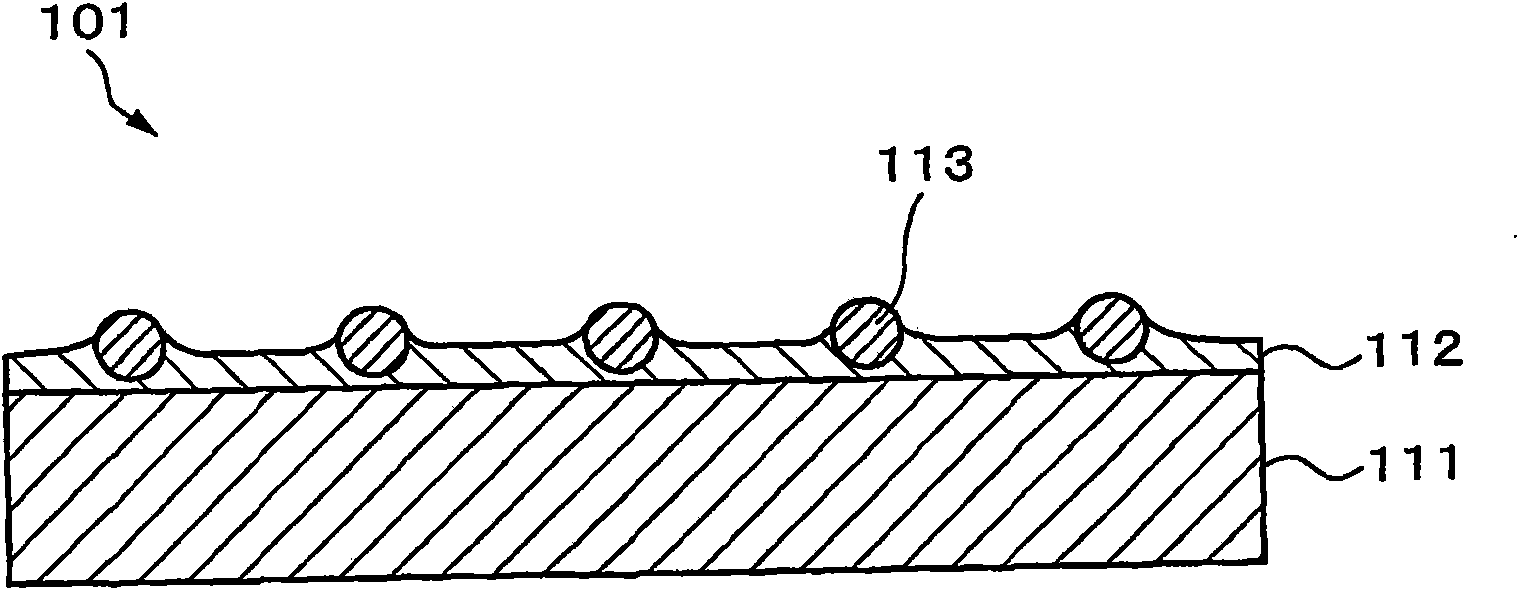

[0201] Next, a second embodiment of the present invention will be described. Although the case where the fine unevenness is formed on the surface of the anti-glare layer 12 by the fine particles 13 has been described in the foregoing first embodiment, the second embodiment will describe the formation of fine unevenness on the anti-glare layer 12 by shape transfer. The case where fine unevenness is formed on the surface.

[0202] (2-1) Structure of anti-glare film

[0203] Figure 12 One example of the structure of the antiglare film 1 according to the second embodiment of the present invention is shown. Such as Figure 12 As shown, the antiglare film 1 includes a substrate 11 and an antiglare layer 12 formed on the substrate 11 . Its structure is similar to that of the first embodiment except that the antiglare layer 12 does not include the fine particles 13 .

[0204] (2-2) Manufacturing method of anti-glare film

[0205] Next, one example of a method of manufacturing t...

no. 3 approach

[0217] (3-1) Structure of touch screen

[0218] Figure 14 is a sectional view of one example of the structure of the touch panel according to the third embodiment of the present invention. The touch screen is a resistive film type touch screen. It is set on various display devices, such as image 3 The display surface side of the illustrated liquid crystal display device constitutes a touch panel display.

[0219] The lower substrate 62 is a light-transmitting substrate such as glass. A transparent electrode film 64 is formed on the lower substrate 62 . Dot spacers 67 are formed on the transparent electrode film 64 . The insulating spacer 66 is arranged on the peripheral portion of the lower substrate 62 . The transparent film 63 is arranged to face the lower substrate 62 via the air layer 68 . The transparent film 63 becomes the surface of the touch panel that is pressed by a finger, a pen, or the like. It is a flexible film that deforms in response to pressure from a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com