Photocuring rapid prototyping system

A light-curing and fast technology, applied in the field of new light-curing rapid prototyping systems, can solve the problems of slow point scanning, high system and operating costs, and low forming efficiency, and achieve the effects of simple control, saving photosensitive resin, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

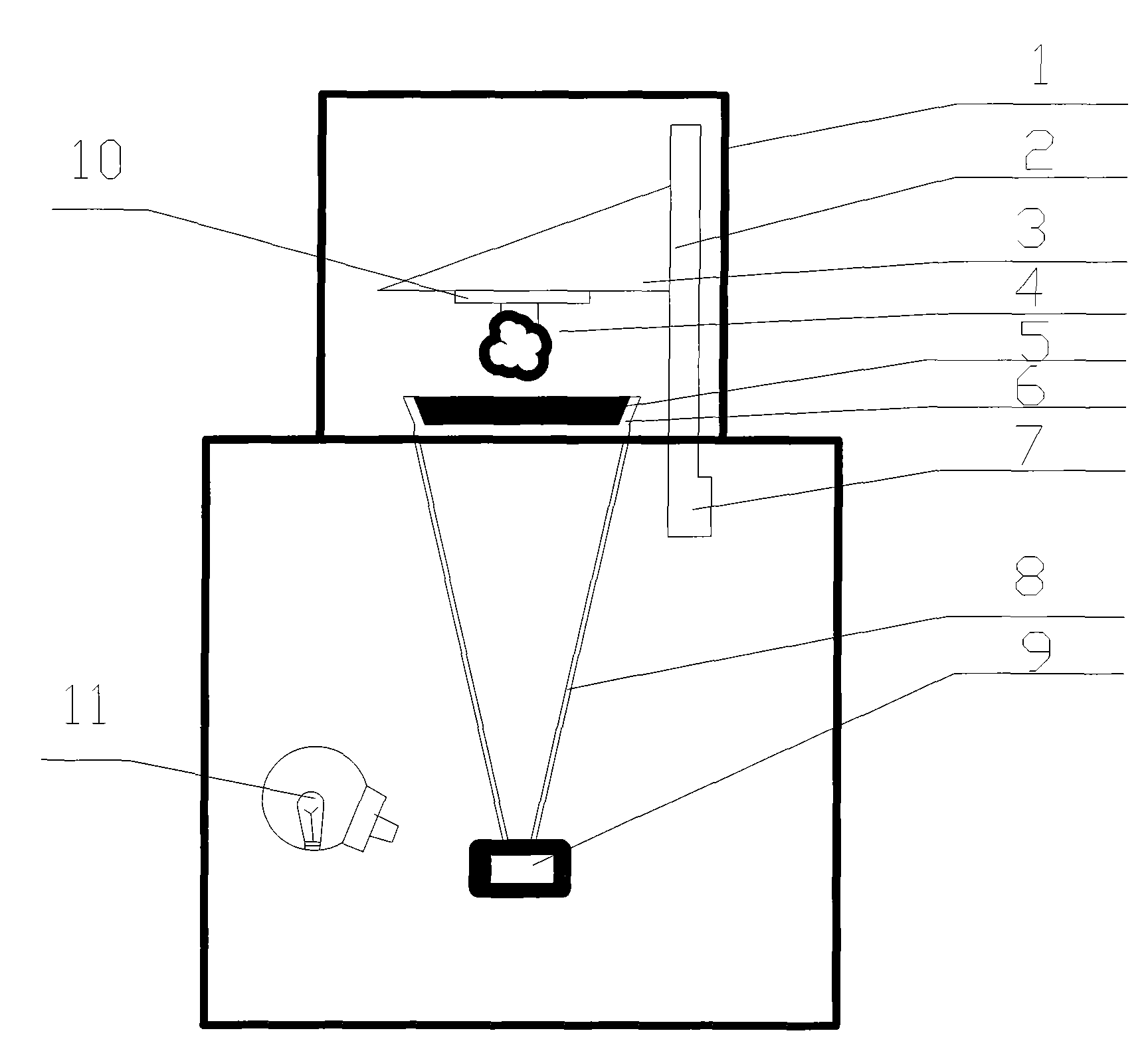

[0015] The invention discloses a new light-curing rapid prototyping system based on digital micromirror technology. The system consists of two parts: a processing and forming system and a digital micromirror device projection device. figure 1 And example the present invention is described in further detail.

[0016] like figure 1 As shown, the first part is a processing and forming system, including a protective cover 1 , a slider 2 , a guide rod 3 , a transparent material tray 6 , a stepping motor 7 and a forming table 10 .

[0017] The transparent material tray 6 is used to hold the liquid photosensitive resin 5, the guide rod 3 is located next to the transparent material tray 6, the slider 2 is installed on the guide rod 3, the forming table 10 is installed on the slider 3, and is located above the transparent material tray 6, The guide rod 3 and the stepping motor 7, the slide block 2, the guide rod 3, the transparent material disc 6 and the forming table 10 are all locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com