Method for reducing disadvantageous temperature effect on main girder structure of bridge and deck pavement structure

A technology of temperature effect and bridge deck pavement, which is applied to bridges, bridge parts, bridge construction, etc., can solve the problems of increasing construction cost and unfavorable gradient temperature effect, so as to reduce construction cost, reduce gradient temperature load, and reduce the weight of the beam body. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Such as Figure 1-7 shown.

[0061] A method of reducing adverse temperature effects on bridge girder structures by at least one of the following methods:

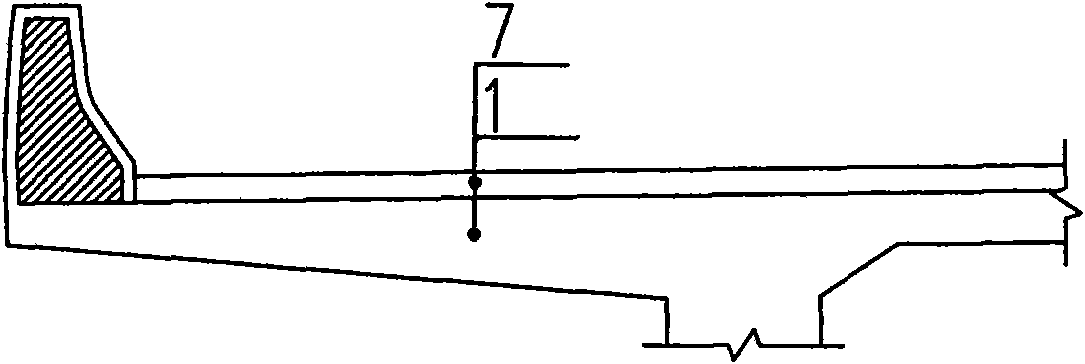

[0062] (1) add heat-insulating material in the waterproof concrete layer on the surface, so that form the pavement layer 7 with heat-insulating waterproof concrete on the bridge girder structure 1 top surface; figure 1 shown.

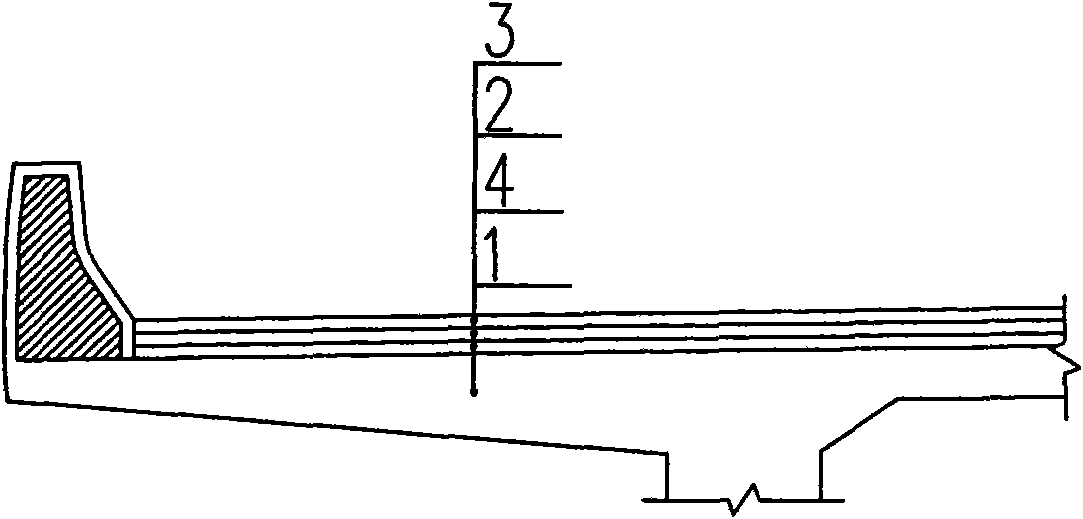

[0063] (2) Pave a layer of temperature insulation layer 4 composed of pressure-resistant materials between the main beam structure 1 of the bridge and the waterproof layer 2, so as to reduce or block the transfer of heat from the surface concrete pavement layer to the main beam structure 1 of the bridge ;Such as figure 2 shown.

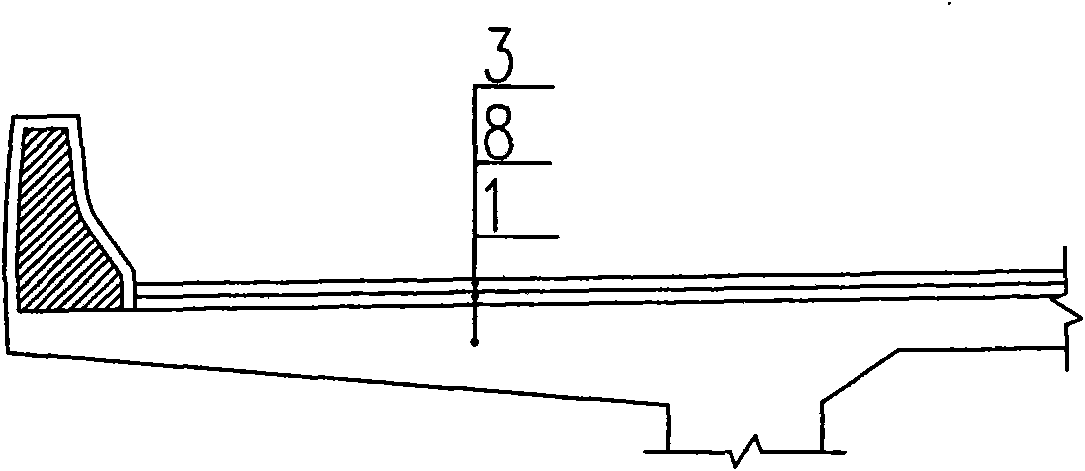

[0064] (3) Add heat insulating material to the waterproof layer between the bridge girder structure 1 and the concrete pavement layer 3, so as to form a barrier between the bridge girder structure and the concrete pavement layer that can reduce or block heat tra...

Embodiment 2

[0071] Such as figure 2 shown.

[0072] A bridge deck pavement structure for reducing the unfavorable temperature effect of a bridge girder structure, comprising a waterproof layer 2 and a concrete pavement layer 3 successively paved on a concrete bridge girder structure 1, and a waterproof layer 2 and a bridge girder structure 1 Between the waterproof layer 2 and the concrete pavement layer 3 there is a temperature insulation layer 4 at the same time or separately, the thickness of the temperature insulation layer 4 is 1-100mm, and the thermal conductivity is not greater than 0.8W / m·k.

[0073] During specific implementation, in order to improve the heat insulation effect, the heat insulation material that forms the heat insulation layer 4 can also be mixed in the concrete pavement layer 3 or the waterproof layer 2, such as figure 1 , 3 As shown, the amount of mixing can be less than the amount of materials used in the above-mentioned temperature insulation layer 4, and ca...

Embodiment 3

[0076] Such as Figure 5 shown.

[0077] A bridge deck pavement structure for reducing the unfavorable temperature effect of a bridge girder structure, comprising a concrete leveling layer 5, a waterproof layer 2 and an asphalt concrete pavement layer 6 sequentially paved on a concrete bridge girder structure 1, wherein:

[0078] (a) between the asphalt concrete pavement layer 6 and the waterproof layer 2;

[0079] (b) Between the waterproof layer 2 and the concrete leveling layer 5;

[0080] (c) Between the bridge girder structure 1 and the concrete leveling layer 5;

[0081] At least one of the above (a), (b) and (c) is provided with a temperature insulation layer 4, the thickness of the temperature insulation layer 4 is 1-100mm, and the thermal conductivity is not greater than 0.8W / m·k.

[0082] Same as above, in order to improve the heat insulation effect during specific implementation, at least one of the three of the asphalt concrete paving layer 6, waterproof layer 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com