Method for testing flame retardant property of asphaltum

A test method and flame retardant performance technology, which is applied in the field of asphalt flame retardant performance testing, can solve problems such as the inability to reflect the combustion process of road asphalt well, and achieve the effects of easy research, simple process, and low requirements for production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

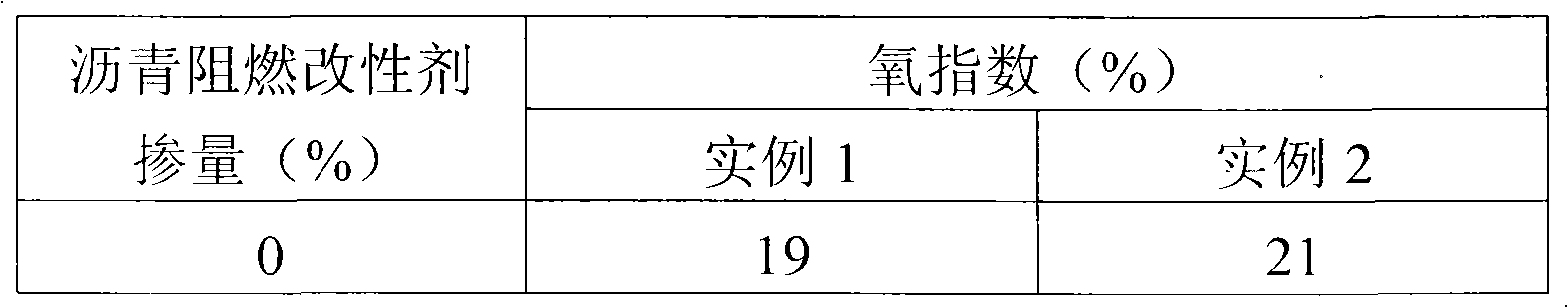

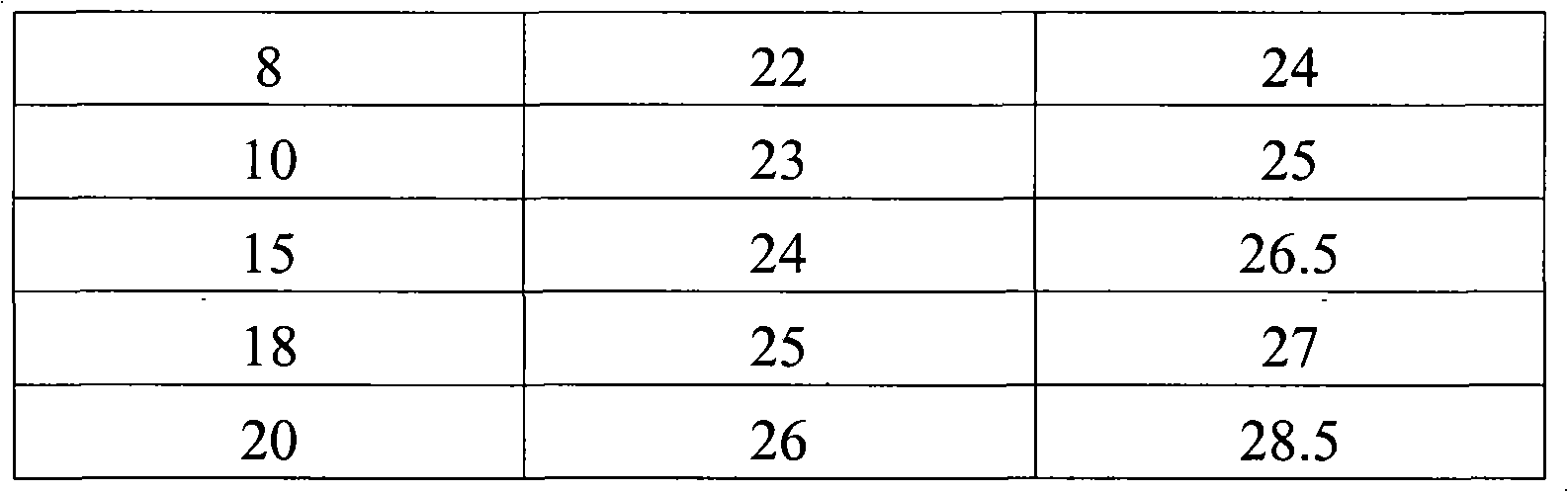

[0044] Example 1: Preparation of flame-retardant asphalt sample by glass fiber mat method

[0045] a. Weigh the molten asphalt and stir it at a constant speed at a constant temperature of about 160°C;

[0046] b. Weigh the asphalt flame retardant modifier (refer to Table 3 for the amount of the asphalt flame retardant modifier), and add it to the asphalt in step a and stir evenly. After completion, continue to stir for 0.5h, and keep the temperature at about 160°C, then Cut for 50min;

[0047] c. Cut a piece of 140×140 glass fiber mat with a weight of (8±0.5) g, place it horizontally on a glass plate coated with a release agent, and pour (80±2) g of the above-mentioned asphalt on the glass evenly fiber mat;

[0048] d. After cooling to room temperature, cut it into 80-120mm long and (6.5±0.5)mm wide samples, and each group of samples should not be less than 15 pieces.

example 2

[0049] Example 2: Adopt the method of the present invention (mineral powder method) to prepare flame-retardant asphalt sample

[0050] (i) Weighing the molten pitch and stirring at a constant speed at a constant temperature of about 160°C;

[0051] (ii) be 1: 1 to take by weighing mineral powder by the rubber powder ratio (weight ratio) of asphalt and mineral powder, and take by weighing asphalt flame retardant modifier (the amount of asphalt flame retardant modifier is referred to Table 3), asphalt Add the flame retardant modifier to the asphalt in step i and stir evenly. After completion, continue to stir for 0.5h to fully dissolve the asphalt flame retardant modifier masterbatch. Keep the temperature at about 160°C, and then cut for 50 minutes;

[0052] (iii) Add mineral powder and stir evenly, cool to about 60°C, roll it into a stainless steel mold with a width of 10mm, a length of 340mm, and a thickness of 5mm and take it out;

[0053] (iv) After cooling to room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com