Manufacturing method of radiating module

A manufacturing method and technology of heat dissipation module, applied in ion implantation plating, metal material coating process, coating and other directions, can solve problems such as inability to weld, and achieve the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

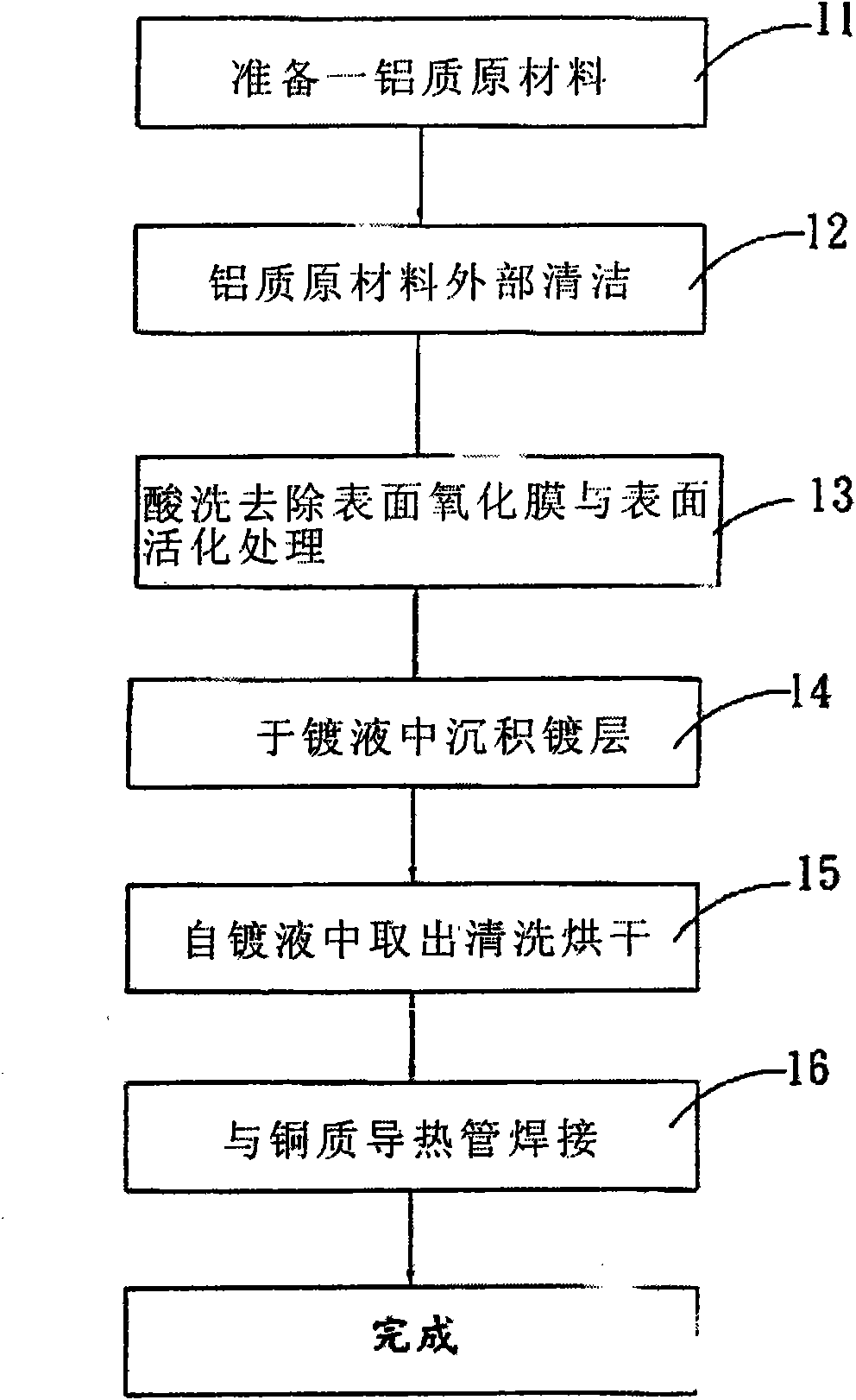

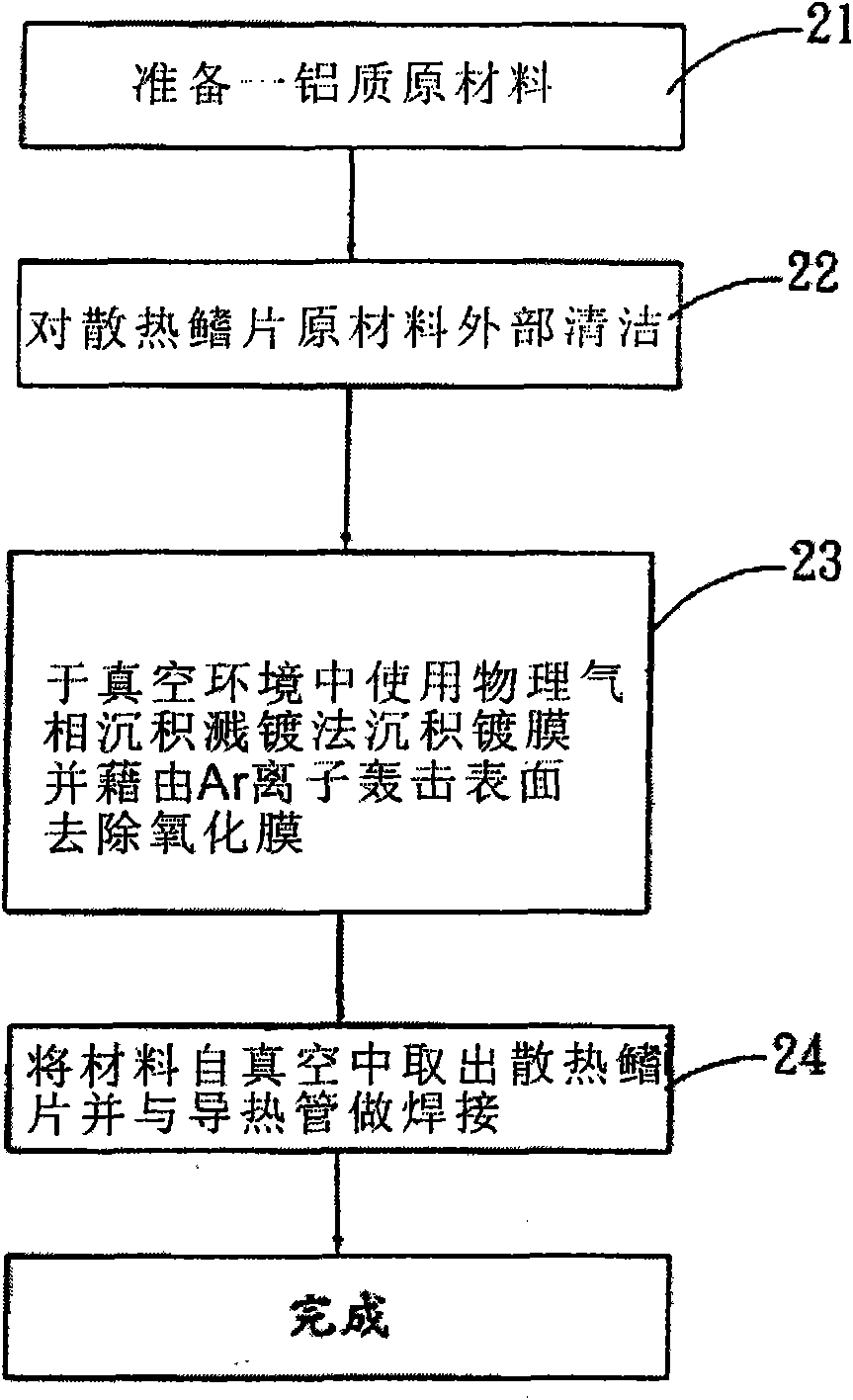

[0061] In order to achieve the above-mentioned purpose and effect, the technical means and structure adopted by the present invention are hereby illustrated in detail with respect to the preferred embodiments of the present invention. Its features and functions are as follows, so that it can be fully understood.

[0062] However, in the present invention, the aluminum heat dissipation fins in the heat dissipation module are partially plated with nickel by physical vapor deposition. In the present invention, the plasma sputtering method is preferably used for illustration.

[0063]The PVD method uses methods such as vacuum, sputtering, ionization, or ion beams to volatilize pure metals and interact with gases such as hydrocarbons and nitrogen, while plasma sputtering is a partially ionized gas. By applying a voltage on two corresponding metal electrode plates, if the concentration of gas molecules between the electrode plates is in a certain range, the secondary electrons genera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com