Air suspension for trailer capable of improving anti-roll capability

A technology of air suspension and capability, applied in the direction of suspension, elastic suspension, vehicle components, etc., can solve the problem of general anti-roll ability, and achieve the effect of improving anti-roll ability and improving handling stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

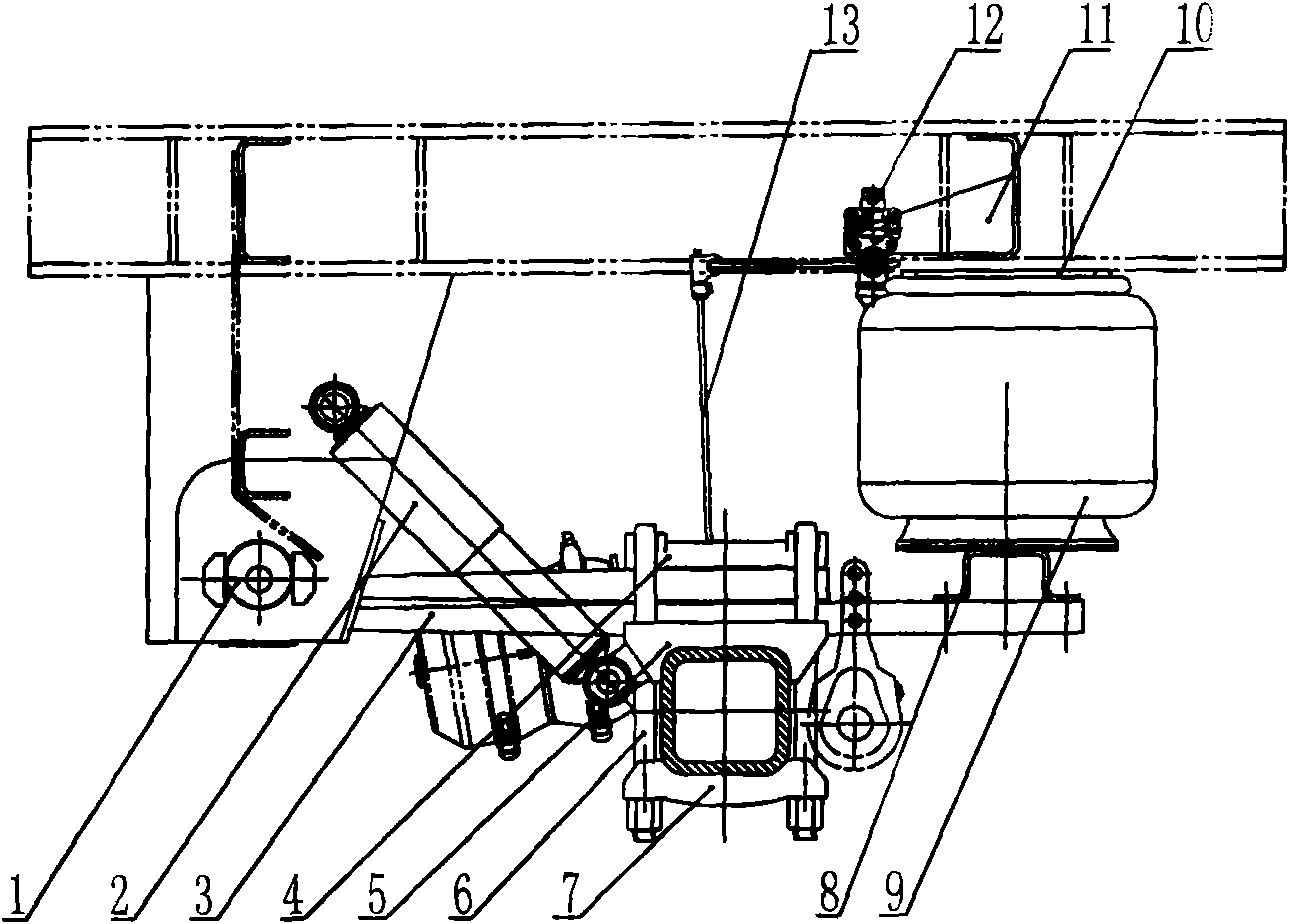

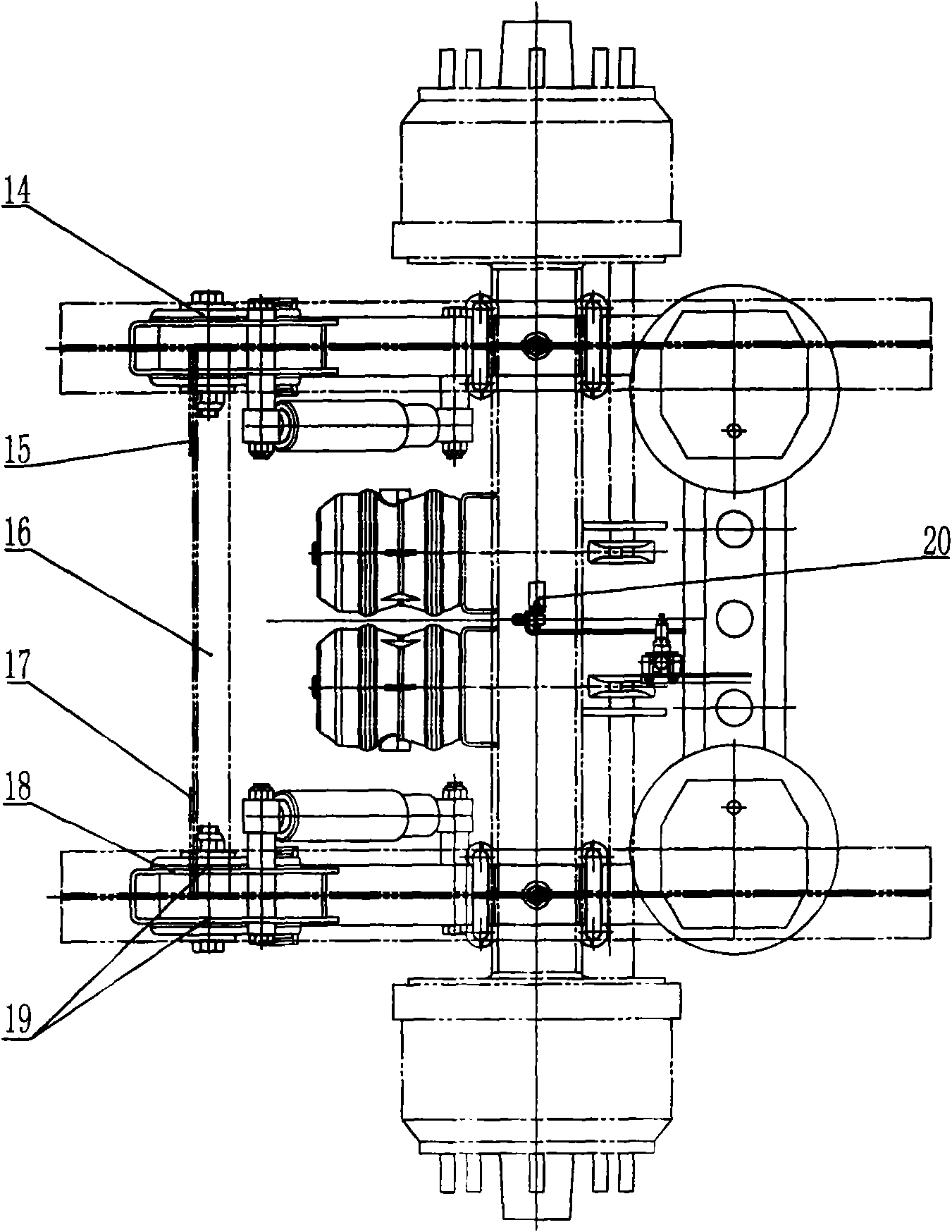

[0011] Below in conjunction with accompanying drawing, the utility model is further described.

[0012] Refer to attached figure 1 , 2 , the left and right bracket assemblies 18, 14 are welded on both sides of the vehicle frame, the upper ends of the left and right reinforcement plates 17, 15 are welded with the frame beams on both sides, and the lower ends are welded with the left and right bracket assemblies 18, 14 respectively, and the reinforcement beams 16 and left and right support assembly 18,14 and left and right reinforcing plate 17,15 welding make it become a whole.

[0013] The two guide arm assemblies 3 are respectively loaded into the inner openings of the left and right bracket assemblies 18, 14, and adjusting spacers 19 are respectively installed between them to adjust their relative gaps; the left bracket assembly 18 and the guide arm assembly 3 pass through The eccentric bushing 1 is connected with bolts to realize front and rear position adjustment during i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com