Wire cable rupture protection system

A protection system, wire rope technology, used in transportation and packaging, load hanging elements, safety devices, etc., can solve problems such as wire rope breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

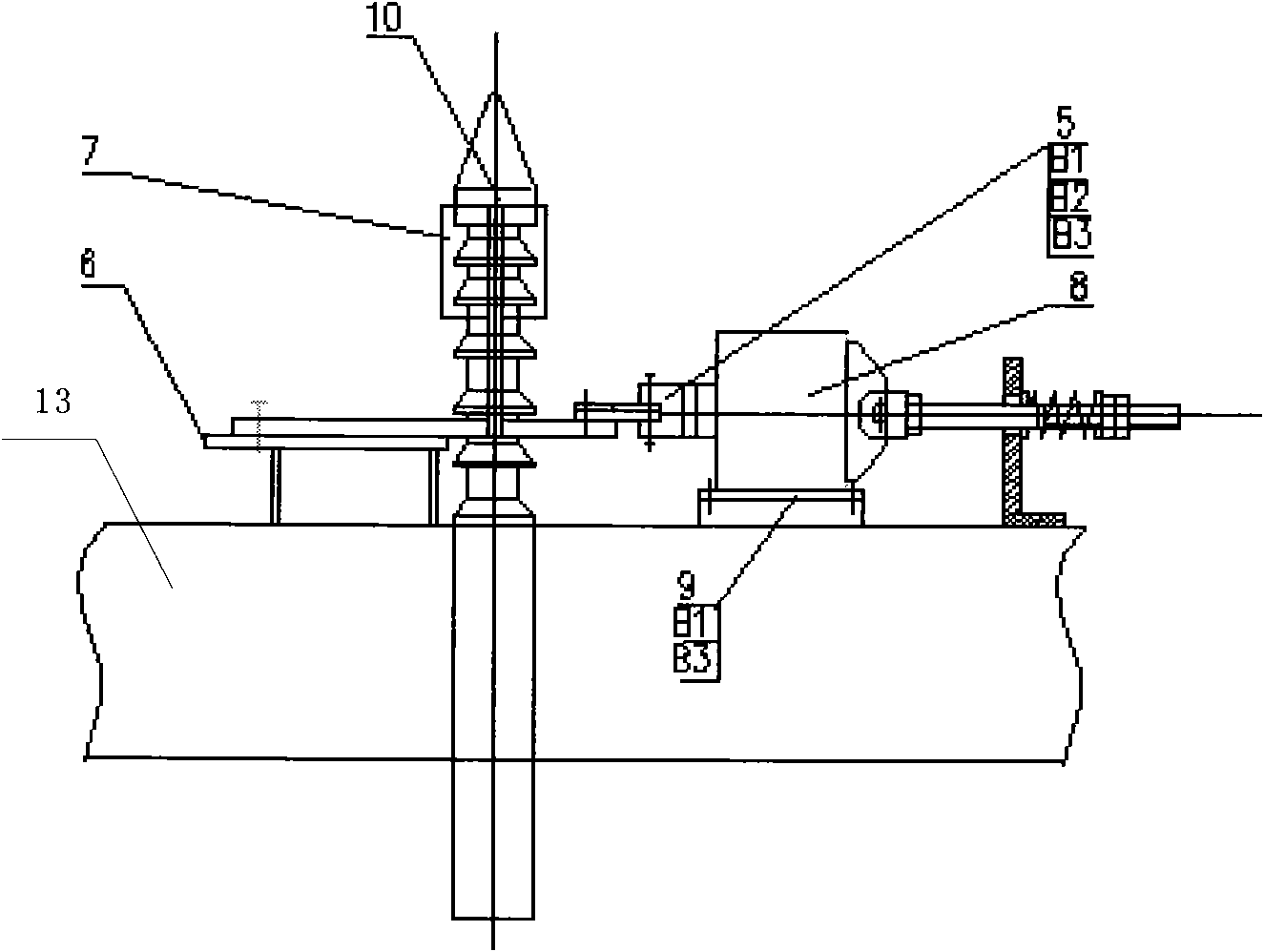

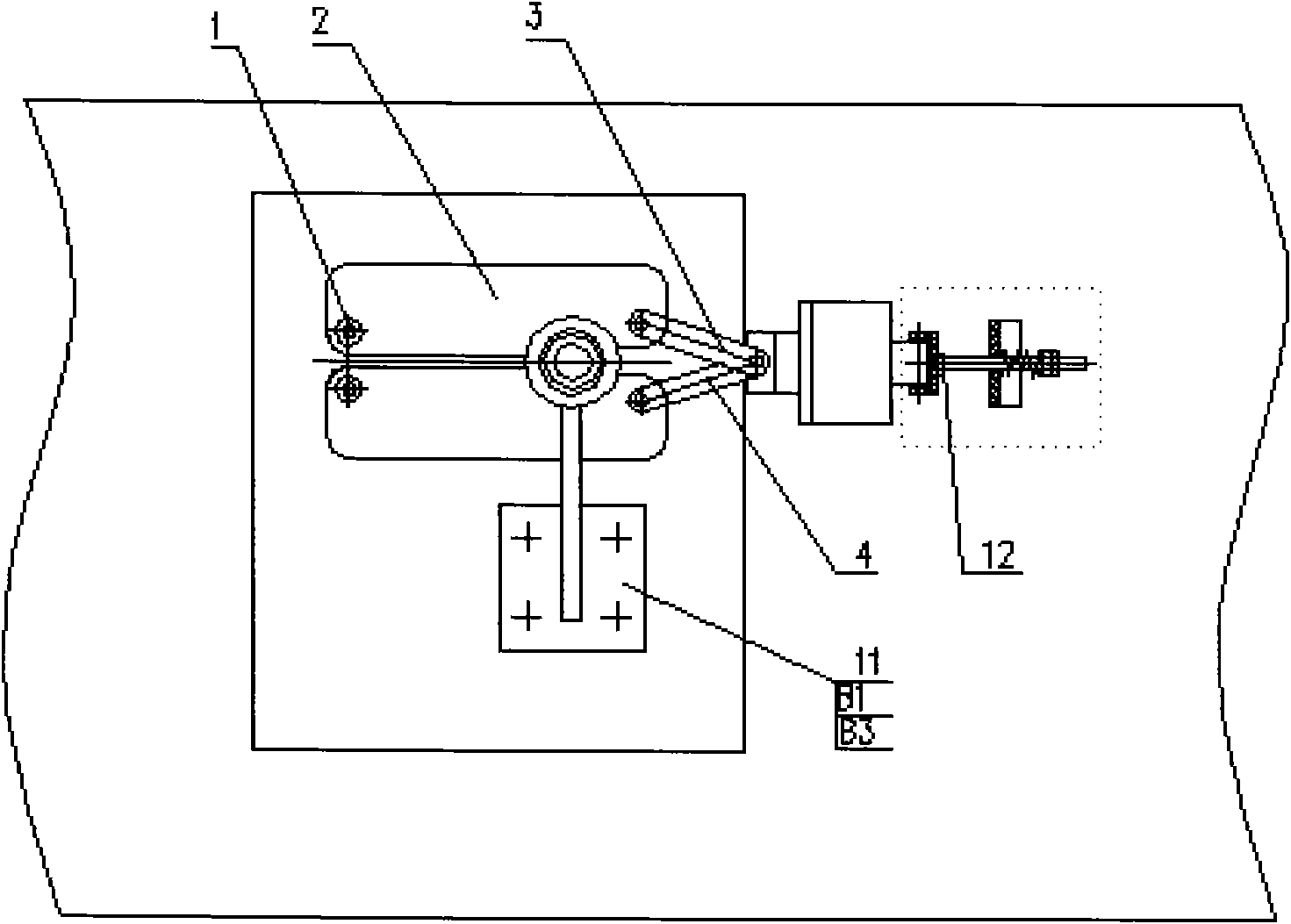

[0015] Such as figure 1 , 2 Shown in the middle: The wire rope break protection system has a safety rod device for synchronous lifting with the clamp suspension beam, a locking mechanism for tightening and releasing the safety rod device, and a control device for controlling tightening and releasing. A sensing device that provides a wire rope break signal to the control device; the lifting safety rod device is a cylindrical safety rod 13 surrounded by layers of annular bosses, each boss has a trapezoidal cross-section; the safety rod The lower end is fixed on the clamp beam or hanging beam. The safety rod is covered with an upper guide sleeve 7. The upper guide sleeve is a cylindrical hollow sleeve, which is always sleeved on the safety rod, which ensures that the safety rod is always up and down in the vertical direction mobile. The upper guide sleeve is fixed on the workbench 13 by bolts B1, nuts B2, and washers B3 through the upper guide sleeve backing plate. The safety lever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com