Method for roasting pyrite in sulfuric acid production

A technology for sulfuric acid production and pyrite, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

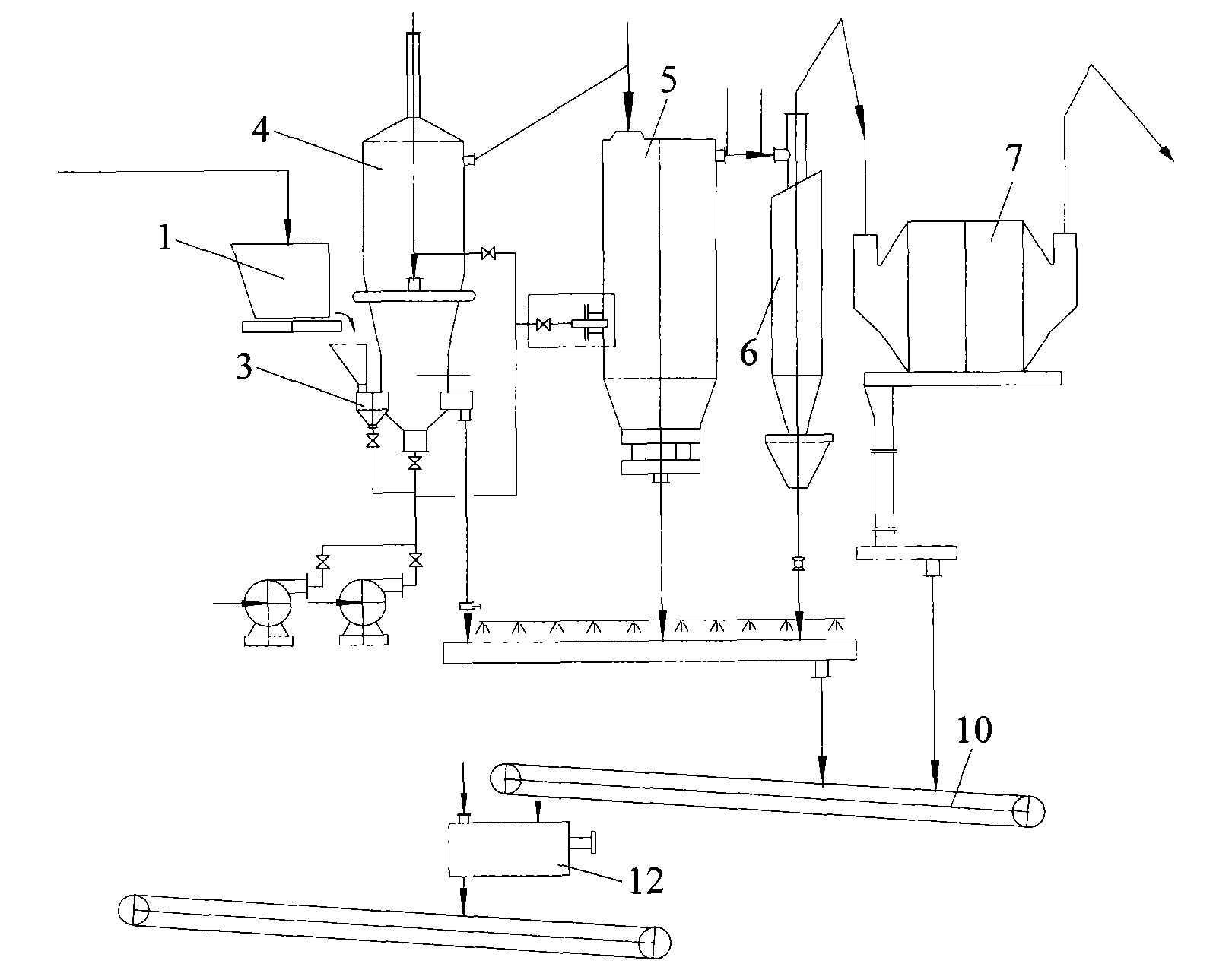

[0029] In the following instructions, you can also use the attached figure 1 To understand the general and preferred embodiments of the invention.

[0030] A design concept of the present invention is to obtain as much iron tetroxide as possible in the roasting stage of pyrite, and to ensure that the elemental sulfur produced in the fluidized furnace is completely oxidized into sulfur dioxide, so as to overcome the problems in the prior art. Technical problems that have long been desired to be solved but cannot be solved.

[0031] For this reason, one of the means that the contriver takes is, on the one hand, controls the oxygen supply of fluidized furnace, roasts pyrite in fluidized furnace at a higher first temperature, so that incomplete oxidation product Fe is obtained in slag. 3 o 4 , on the other hand, add at least one air supply link in the flow path after the fluidized furnace, and carry out secondary or multiple oxidations to the furnace gas (containing sulfur dioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com