Railway ballastless track bridge kerbstone cast-in-situ construction method

A ballastless track and construction method technology, applied to bridges, bridge parts, bridge materials, etc., can solve the problems of high transportation costs, difficult installation, affecting the appearance of bridges, etc., achieve clear force, safe and fast construction, and simplify intermediate transportation link effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

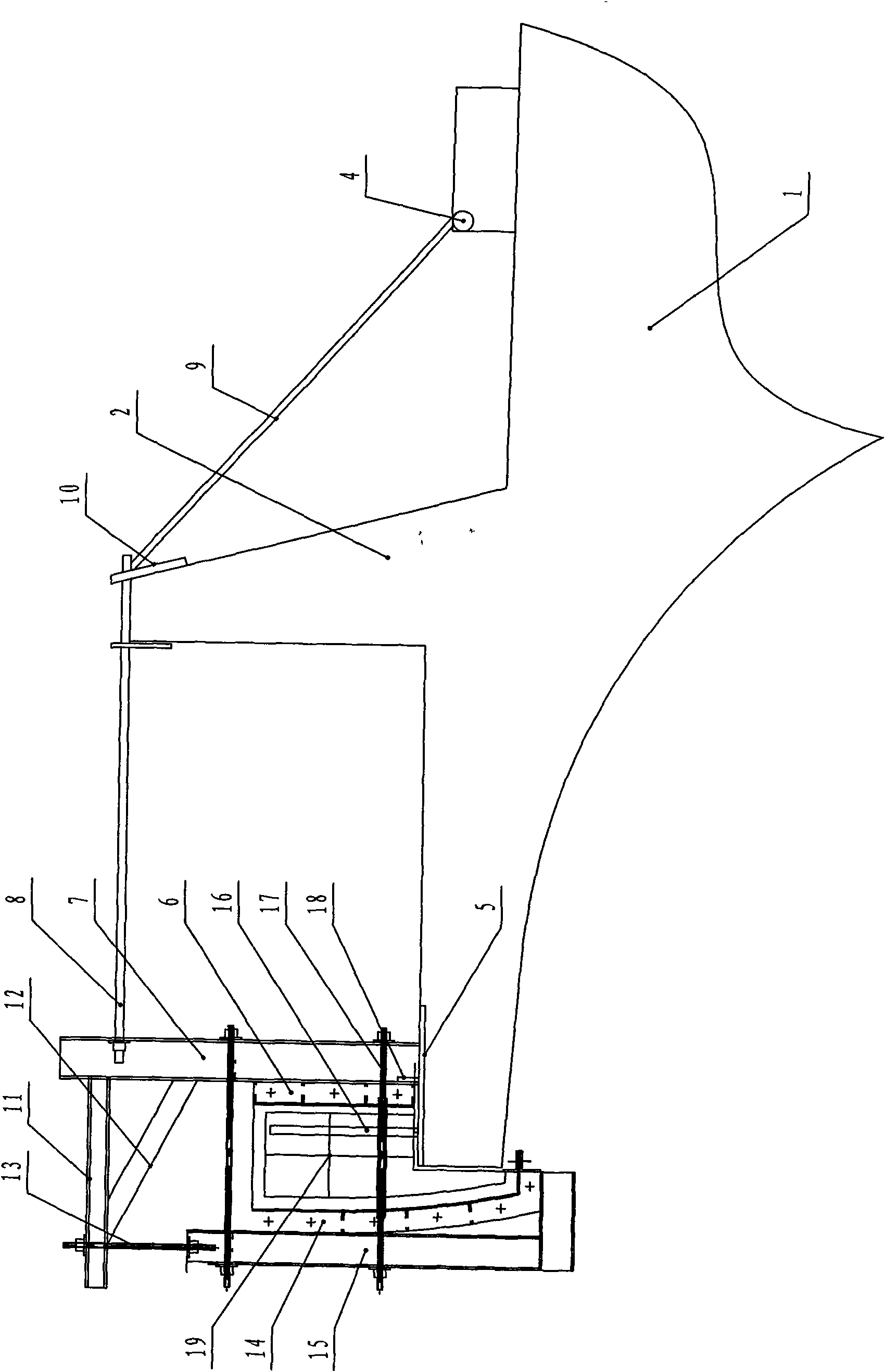

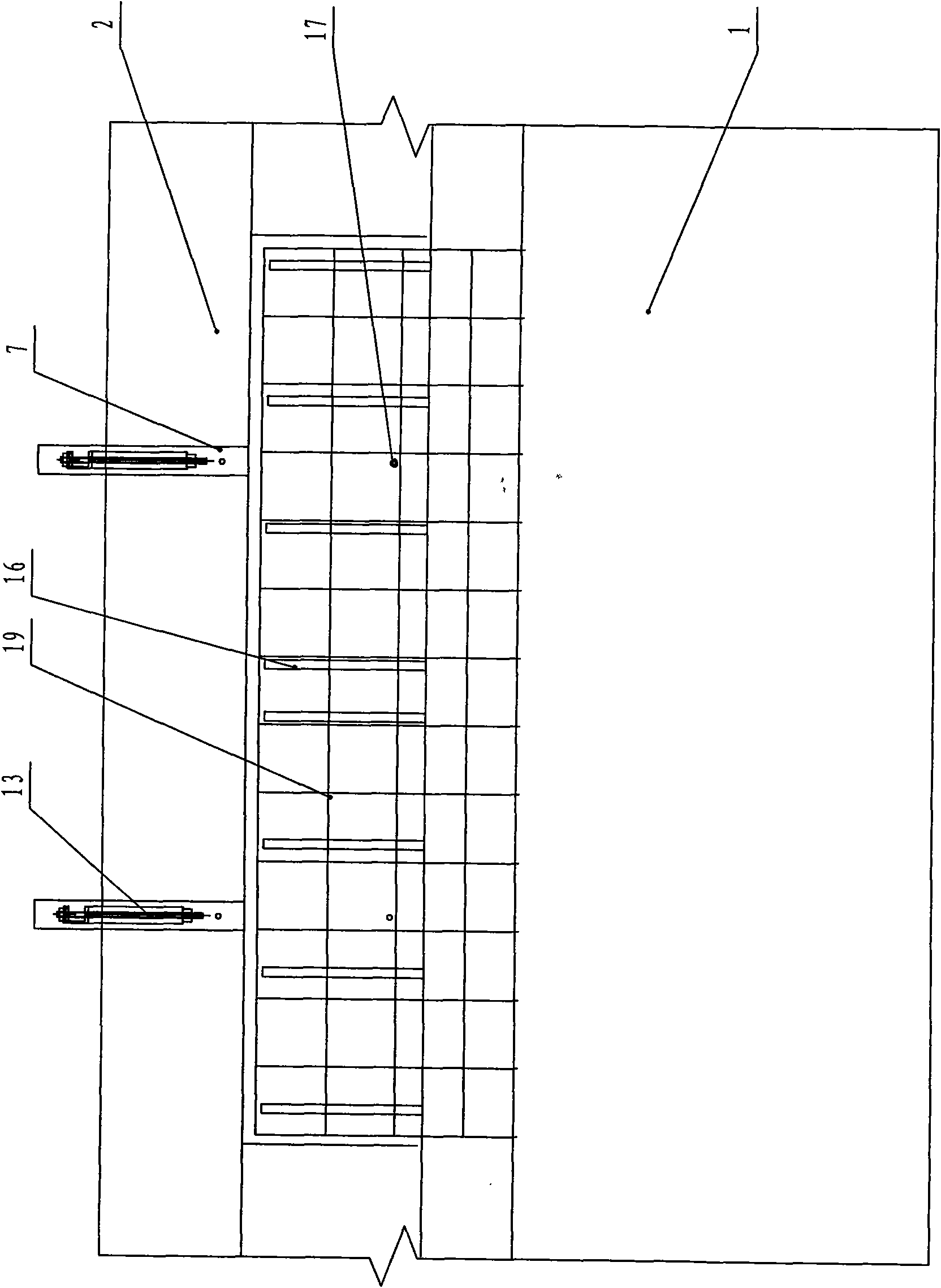

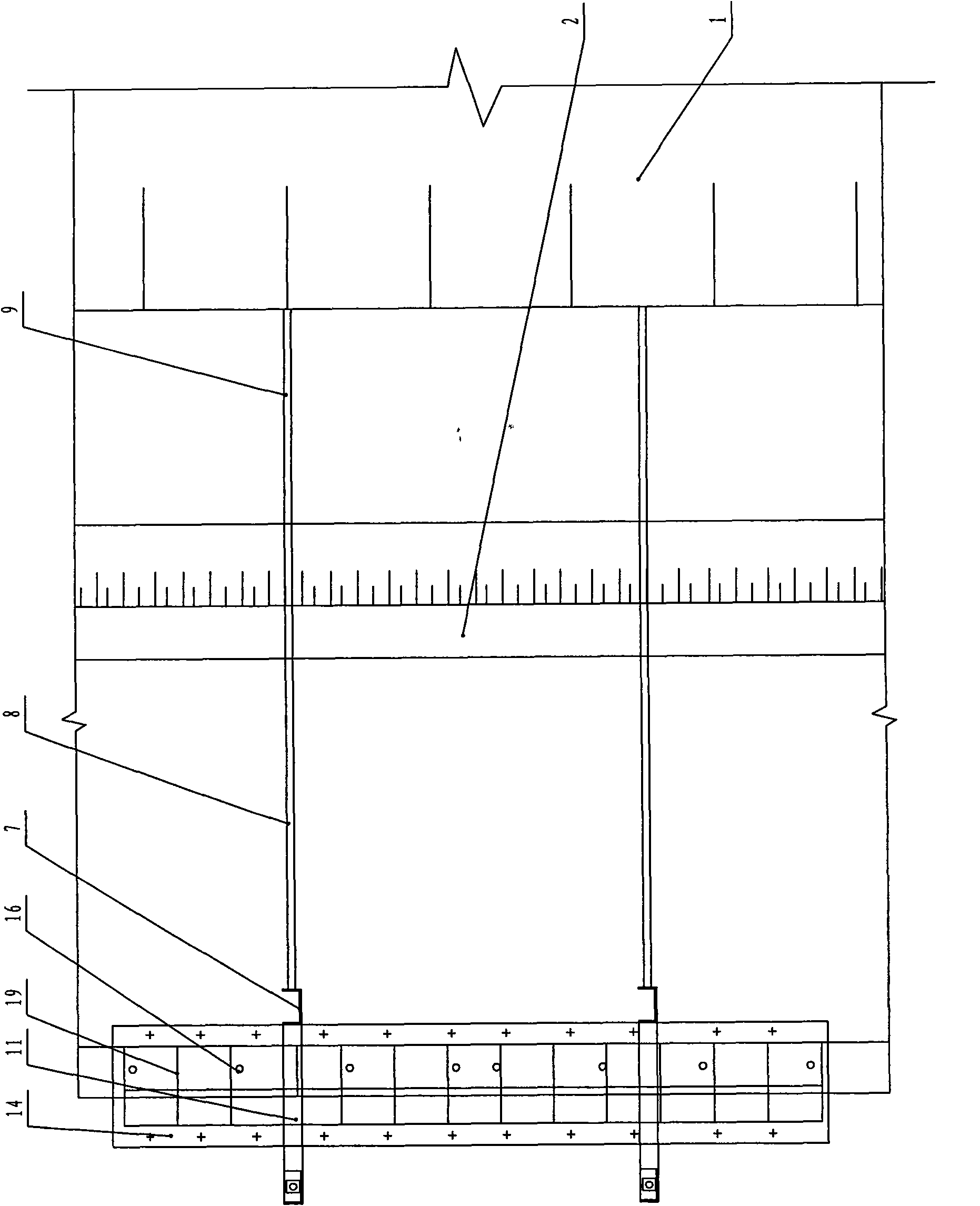

[0024] Embodiments of the present invention will be further described in conjunction with the accompanying drawings.

[0025] like figure 1 , figure 2 , image 3 Shown, construction main points of the present invention are as follows:

[0026] ①Clean up bridge flange plates and embedded bolt holes

[0027] Clean up the debris on the flange plate and the embedded bolt holes to facilitate the installation of the inner formwork bracket and its connection with the beam body.

[0028] ② Install the inner mold and its bracket

[0029] After the bridge flange plate and the pre-embedded bolt holes are cleaned up, the inner mold support 7 and the inner mold 6 are first installed (the inner mold and the inner mold support can be used as a whole), and the lower part of the inner mold support and the inner mold are made of steel bars. The L-shaped fastener 18 is firmly connected to the pre-embedded steel plate 5 of the curb, and then the front tie rod 8 (round steel of Φ20mm) is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com