Rotary piston engine

A technology of rotating pistons and engines, which is applied to internal combustion piston engines, combustion engines, machines/engines, etc., and can solve problems such as high fuel consumption, large volume, and reduced smoothness of engine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

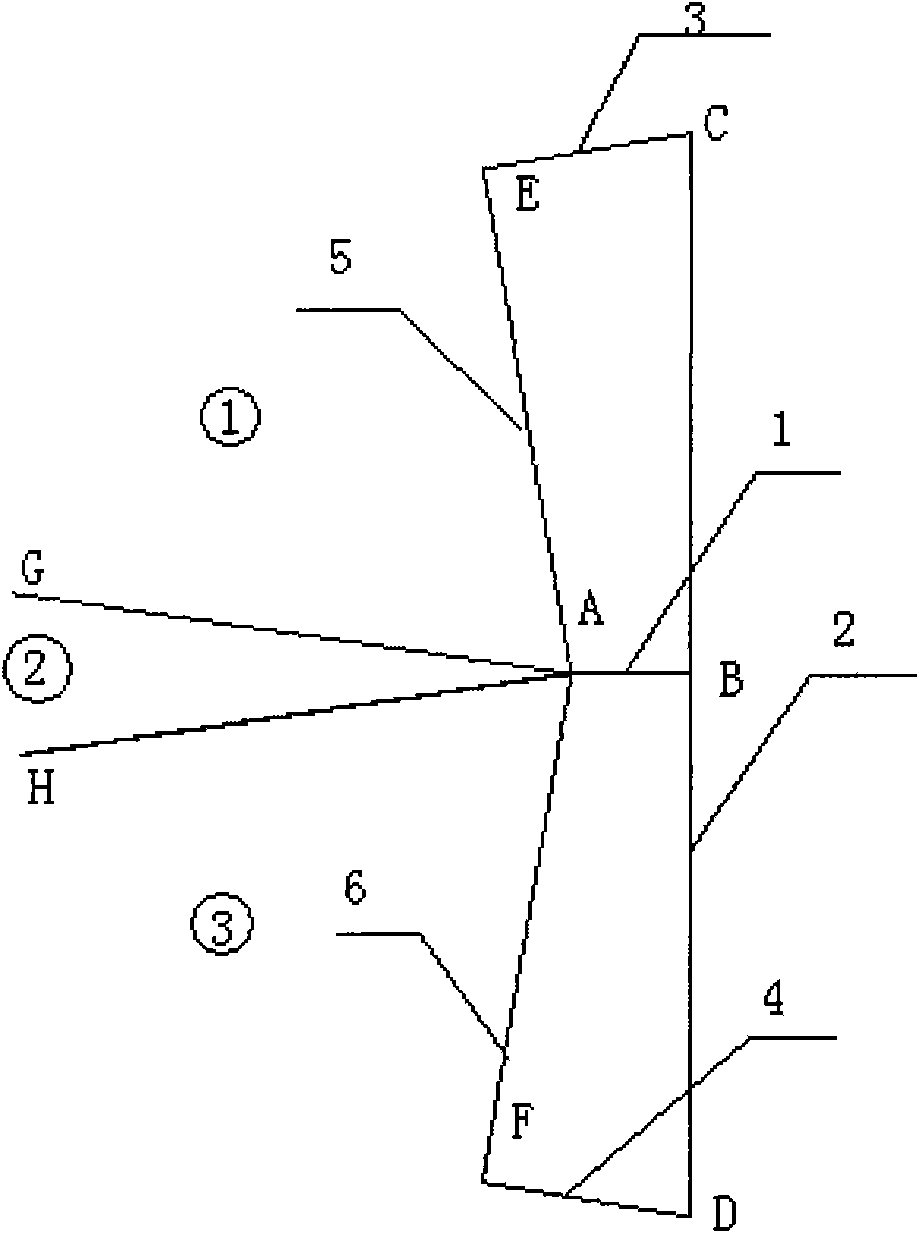

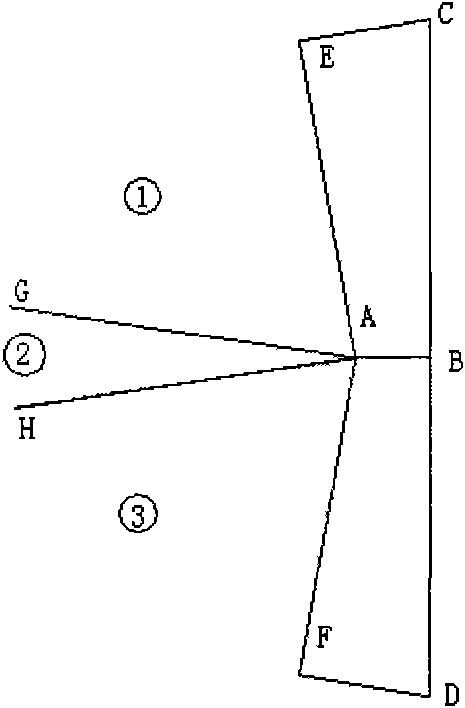

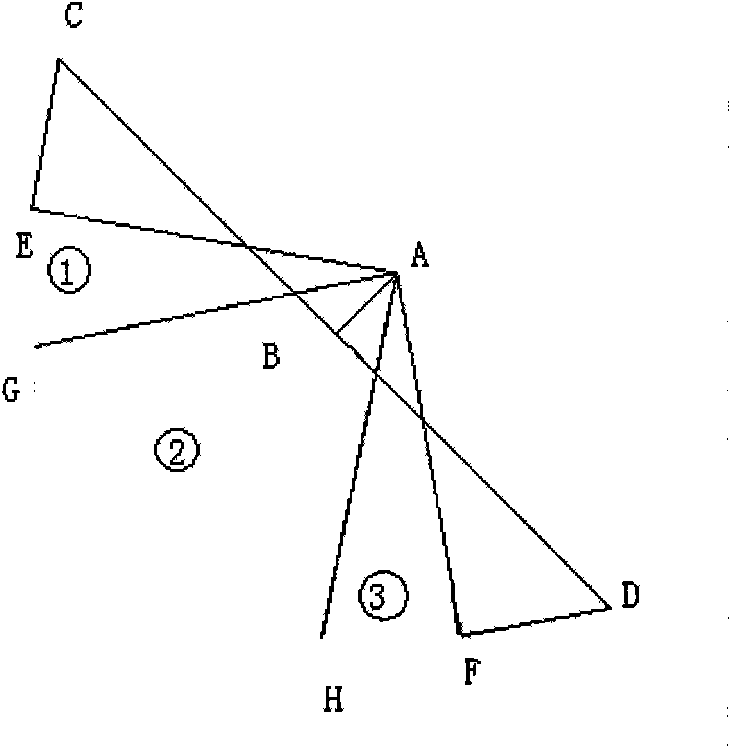

[0024] In the structure shown in Figure 1, if the speed ratio of the output shaft 1 around point A relative to the fixed cylinder and the speed ratio of the rotor 2 around point B relative to the output shaft 1 is 1:-1, then the rotor 2 relative to the fixed cylinder The rotational speed of the body is zero, so the motions of the two ends C and D on the rotor are similar to those of B, and they all do circular motion. The length of the crankshaft 3 is CE, the length of the crankshaft 4 is DF, the length of the push rod 6 is FA, and the length of the push rod 5 is EA. The above points are the hinge centers of the corresponding two parts, and BD=BC, CE =DF, FA=EA. If the output shaft and the rotor rotate continuously, the rotor will drive the two push rods to swing back and forth within a certain range through the two crankshafts. The angle ∠FAE is the largest when the rotor moves to the extreme right, and the angle ∠FAE is the smallest when the rotor moves to the extreme left....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com