Gear rack reciprocating motion mechanism and engine thereof

A reciprocating mechanism, rack and pinion technology, applied in the direction of machines/engines, belts/chains/gears, mechanical equipment, etc., can solve the problems of long service life, stroke loss, etc., and achieve extended working time and compression time Effect of shortening and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

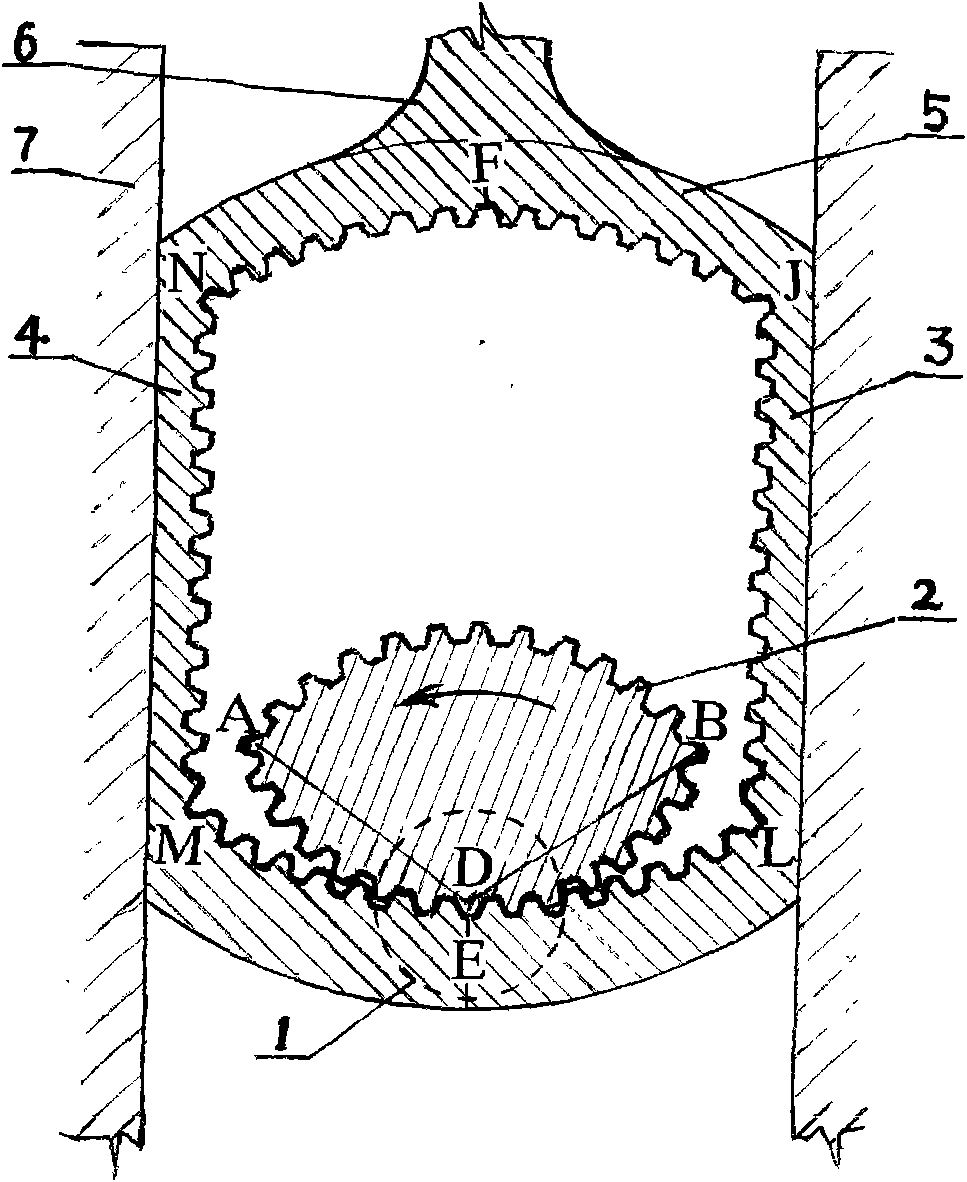

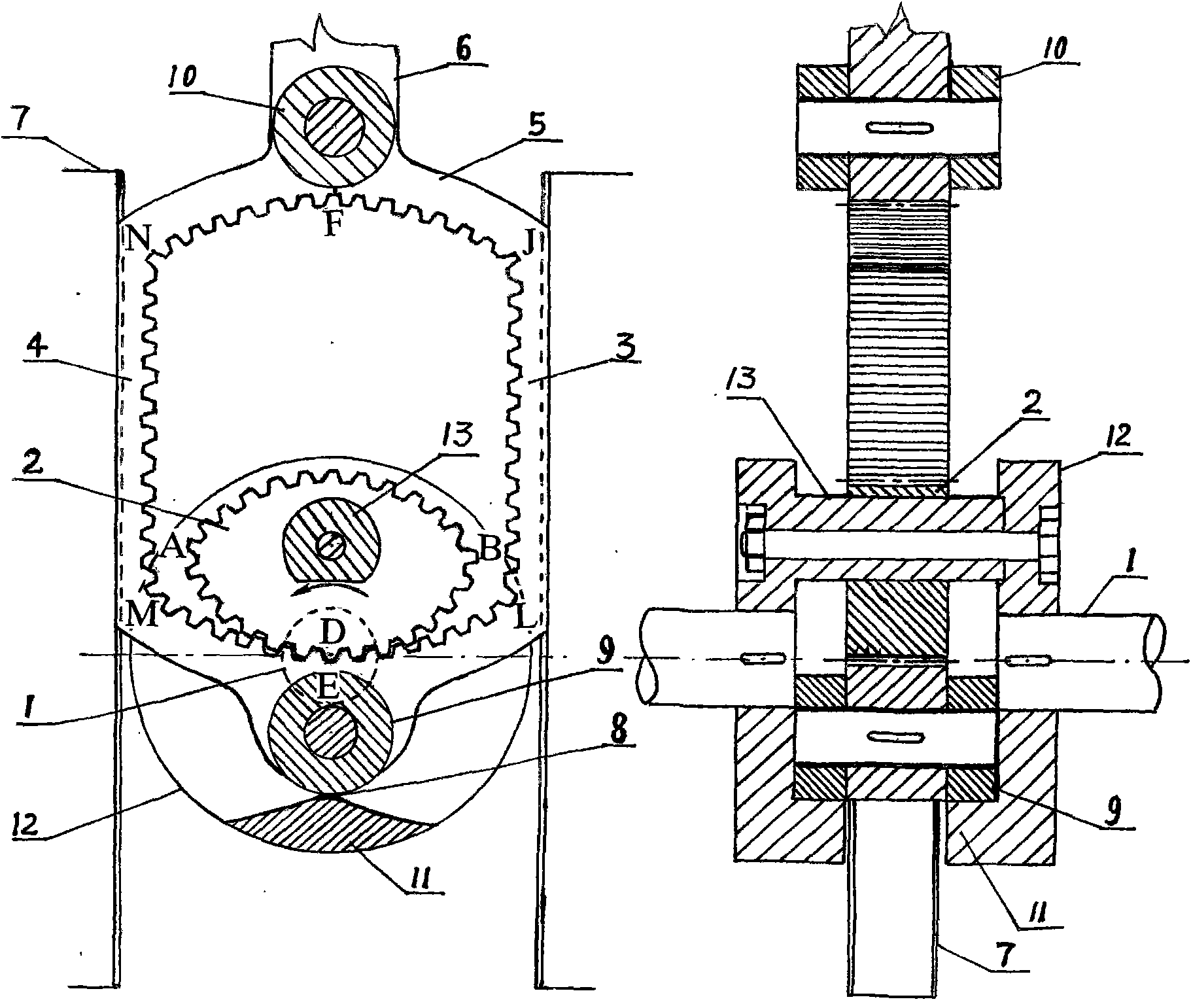

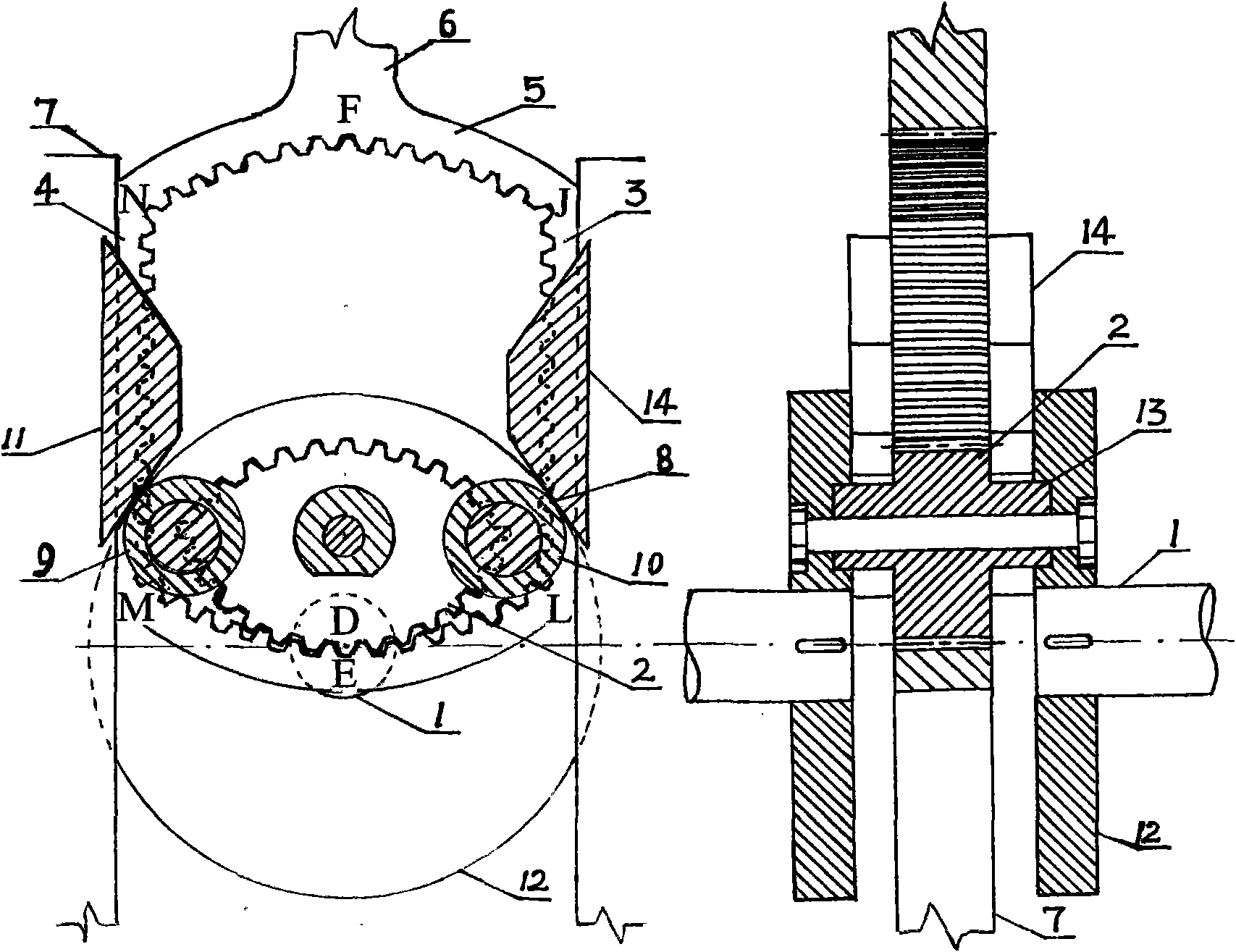

[0033] Such as figure 1 , the half-circular gear (2) installed on the rotating shaft (1) is a gear composed of a part circular gear and a part non-circular gear: the teeth of the part circular gear are the teeth of section AB in the figure, and it is the same as The teeth of ordinary circular gears are arranged in the same way, that is, the distance from each tooth to point D of the gear's rotation center (axis center) is constant. This constant distance is the constant radius of the semicircular gear. That is, the linear distance from D to B or from D to A in the figure; the gear teeth of the non-circular part are the gear teeth of DA and BD two sections, since D is the rotation center of the semicircular gear (2), the A gear tooth with a gear radius of zero. Therefore, the gear teeth of the DA segment, the gear radius from D to A, gradually increases from zero until it is equal to the constant radius, while the gear teeth of the BD segment, the gear radius from B to D, is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com