Non-contact angle/placement detection sensor

A displacement detection, non-contact technology, applied in the field of optoelectronics, can solve the problems of complex structure, small adjustment angle and poor stability of the photoelectric encoder, and achieve the effect of low cost, high precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

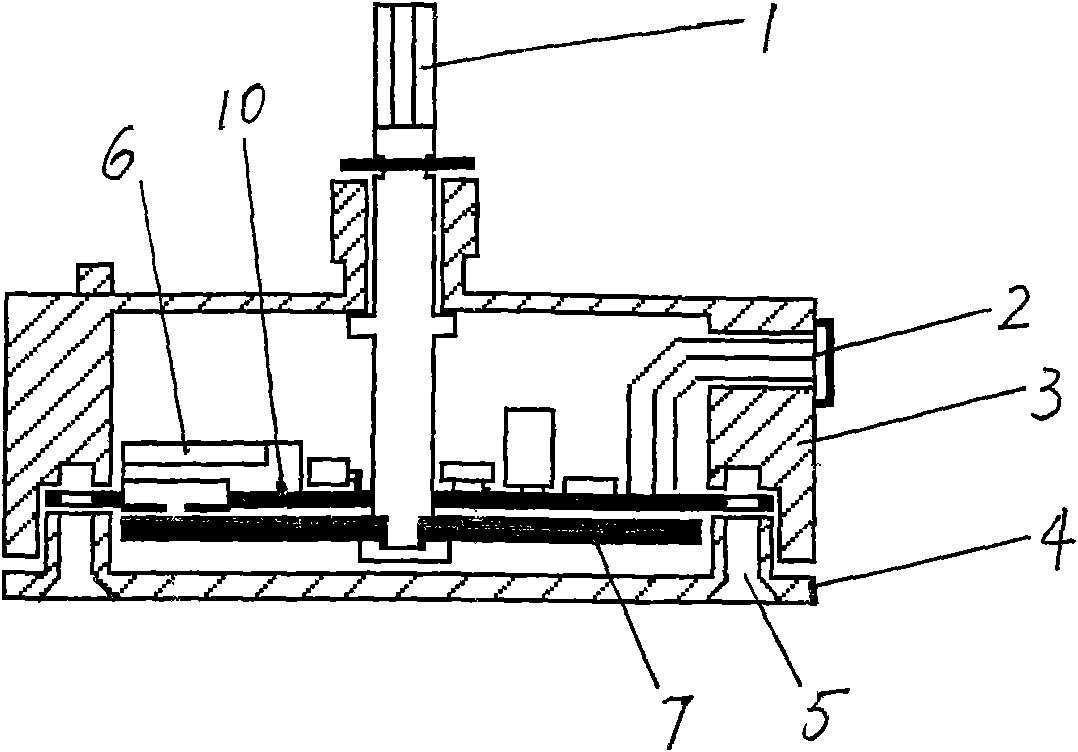

[0026] see figure 1 , the present invention has a cylindrical housing 3, a rotating shaft 1 is installed at the center of the housing 3, and the rotating shaft 1 is designed in a potentiometer damping manner to prevent the rotating shaft from freely rotating. In particular: an image sampling processing system 6 is fixedly installed in the housing 3, and a signal output interface 2 is also installed on the side wall of the housing 3, which is connected to the serial communication circuit of the CPU in the image sampling processing system; 3, the tail end of the rotating shaft 1 is fixedly installed with a special reflector 7; finally, three screws 5 are used to integrate the cover plate 4 and the housing 3, which constitutes the present invention.

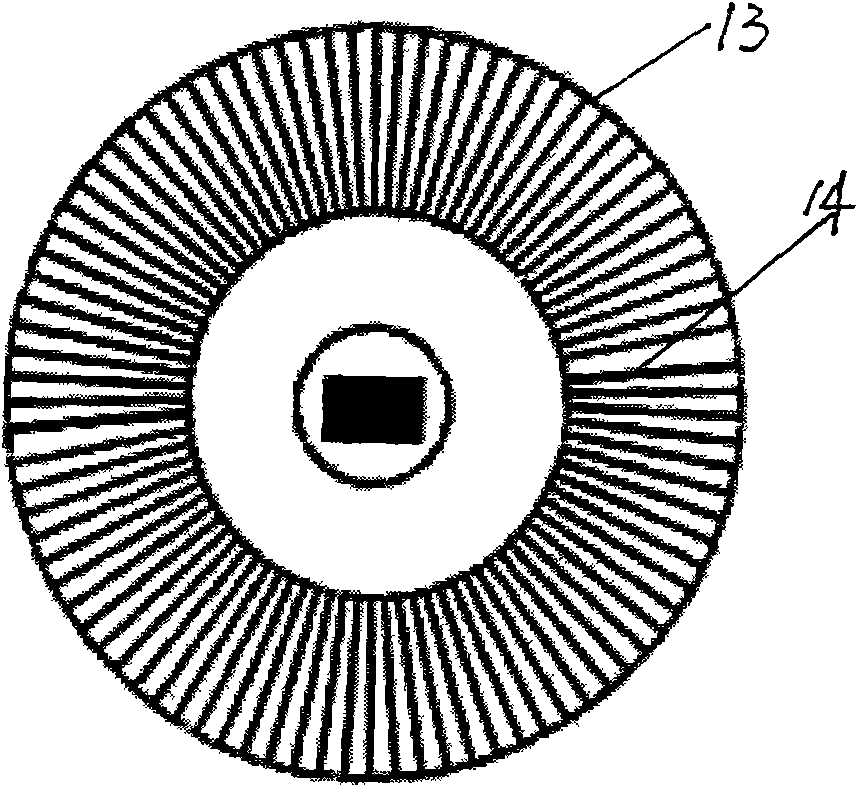

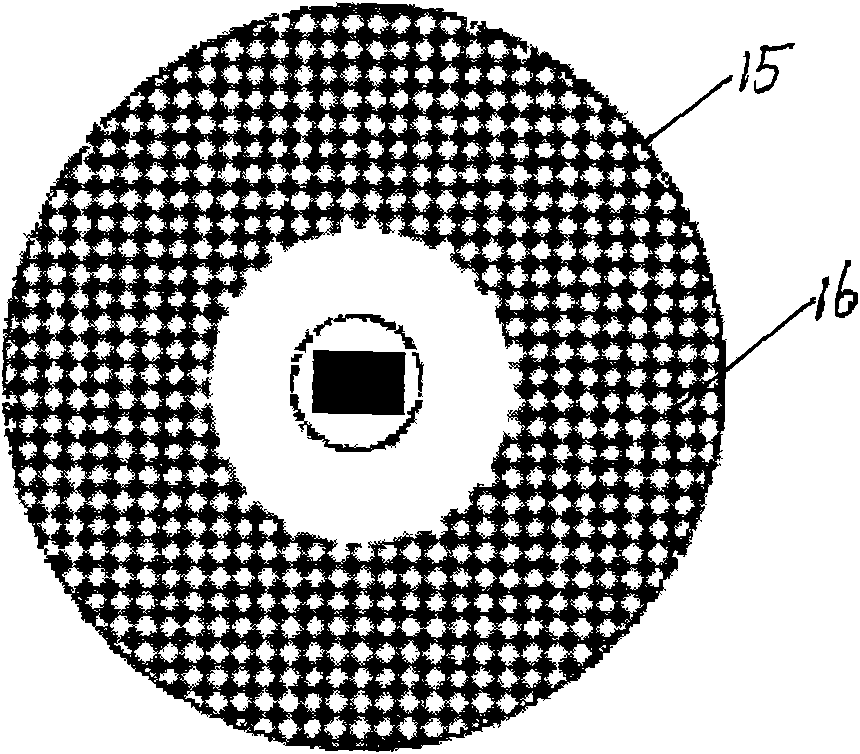

[0027] The reflecting plate 7 among the present invention can have multiple structures, wherein one of structure sees figure 2 , it adopts an epoxy substrate 13 as a substrate, and there are gold-plated fine radiation lines 14 eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com