Control method for processing five-rod five-ring parallel kinematic machine tool

A control method and motion control card technology, applied in the direction of digital control, electrical program control, etc., can solve problems such as ineffectiveness, and achieve the effect of reducing errors, simplifying the operation process, and solving the corresponding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Please refer to the accompanying drawings for a further description of the present invention.

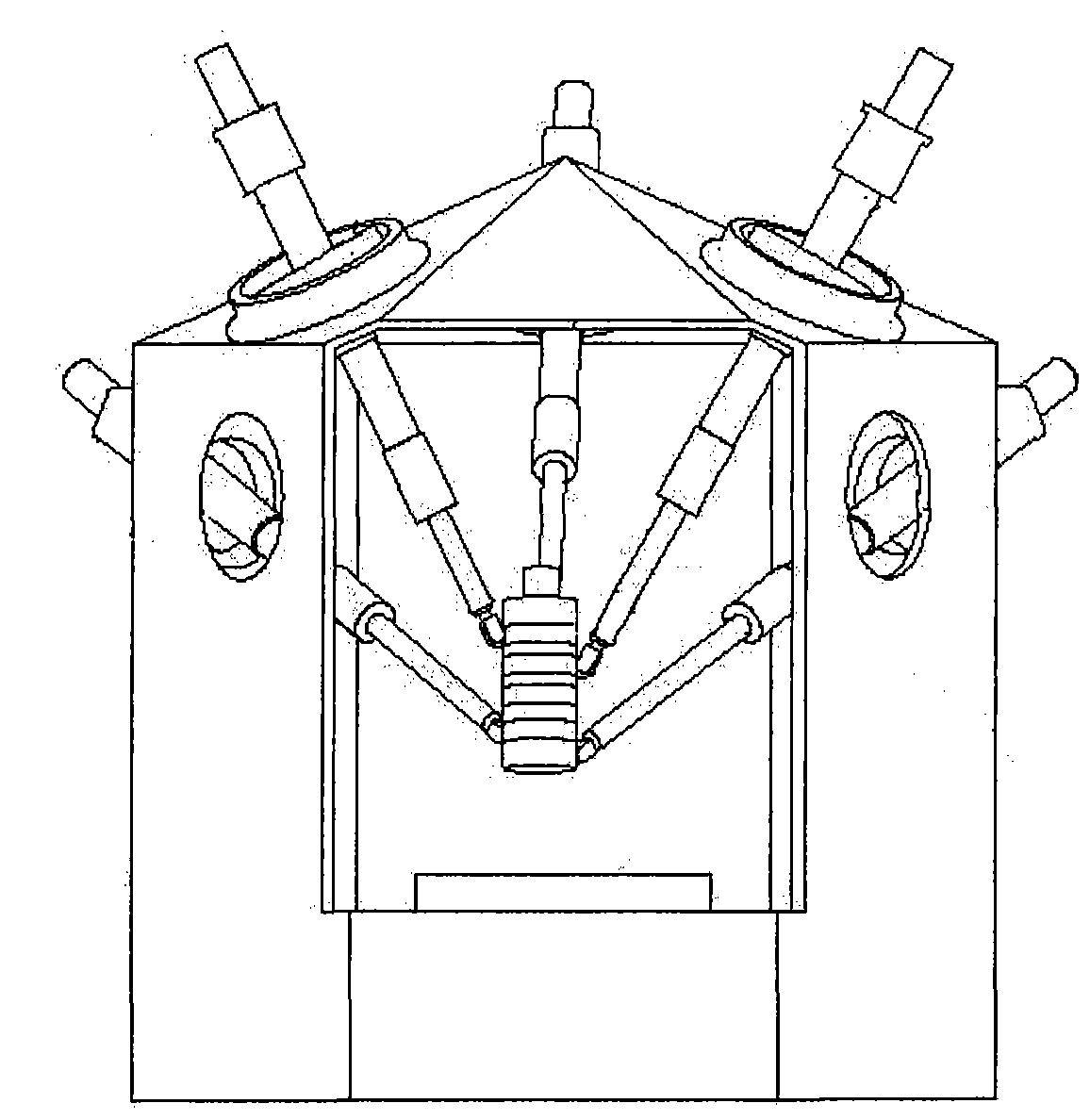

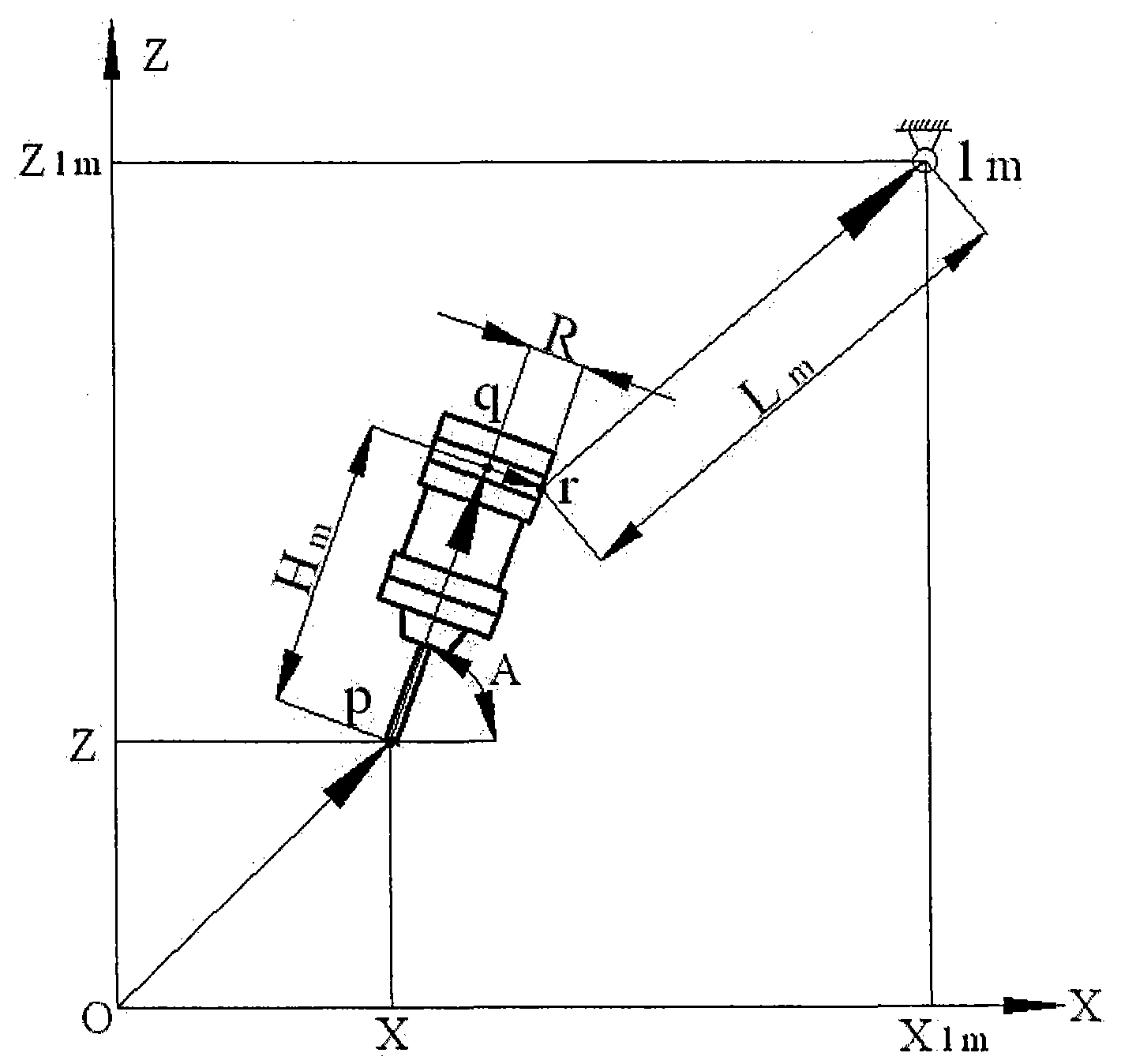

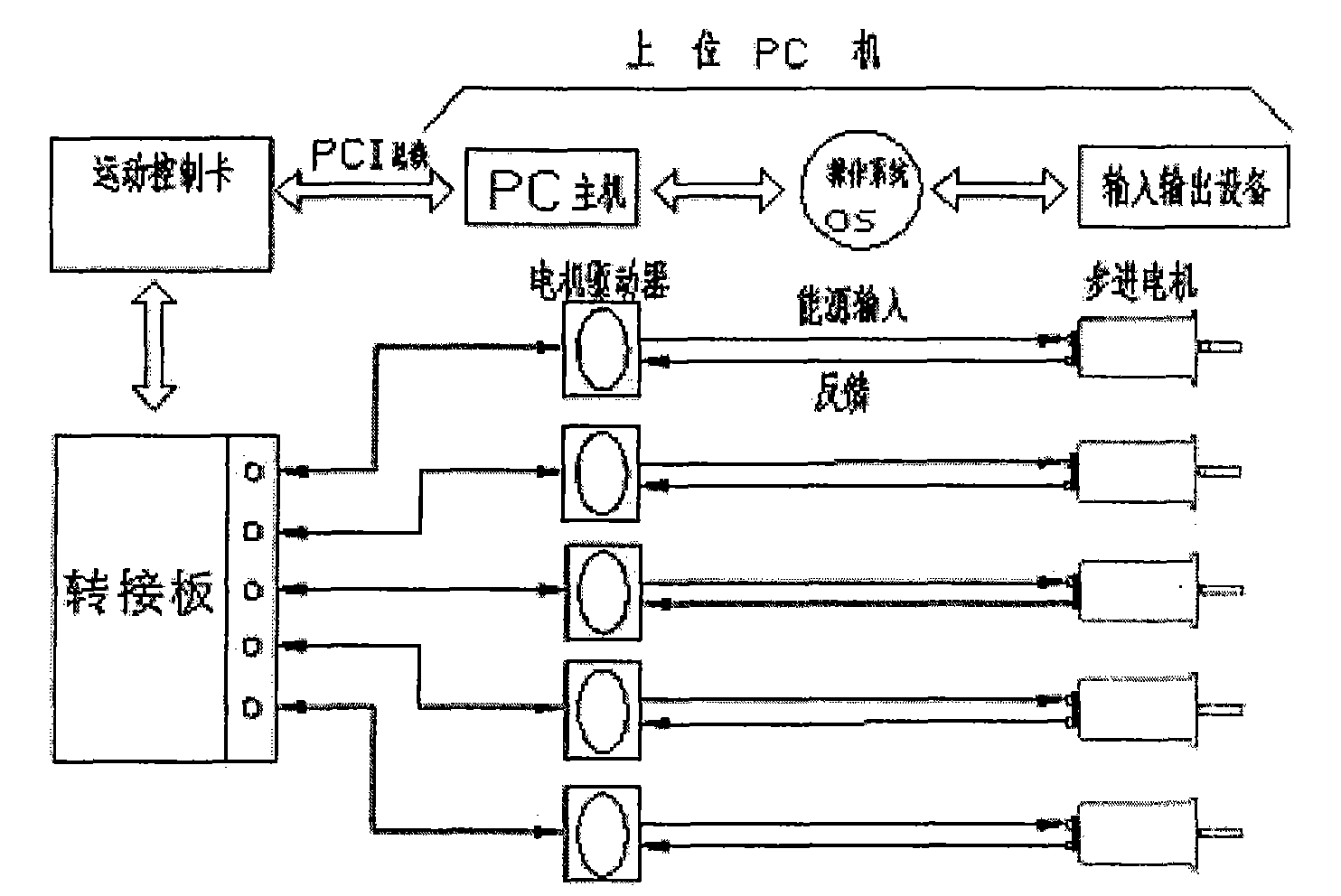

[0046] Such as image 3 As shown, the present invention provides a five-bar five-ring parallel kinematic machine tool processing control method. The numerical control system of the five-bar five-ring parallel kinematic machine tool is bidirectionally connected with the upper PC and the servo control system by a motion control card. The control method includes the following steps: (1) Establishing a control model, which forms a one-to-one functional relationship between the structural geometric parameters of the five-bar five-ring parallel machine tool, the size of the tool, and the mathematical model of the surface of the workpiece to be machined, such as figure 2 As shown, the rod length function is obtained;

[0047] combine Figure 5A , Figure 5B and Figure 5C Introducing the specific implementation of the present invention, the structural dimensions include the rad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com