Electronic tag storage management system

A warehouse management system and electronic label technology, applied in the direction of instruments, computer parts, collaborative operation devices, etc., can solve the problems of increased distribution quantity and frequency, difficulty in meeting the real-time performance of warehouse management, and affecting operation efficiency, etc. The effect of preventing counterfeiting and selling counterfeit goods, improving informatization level and management ability, and improving accident handling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1. Cargo storage management

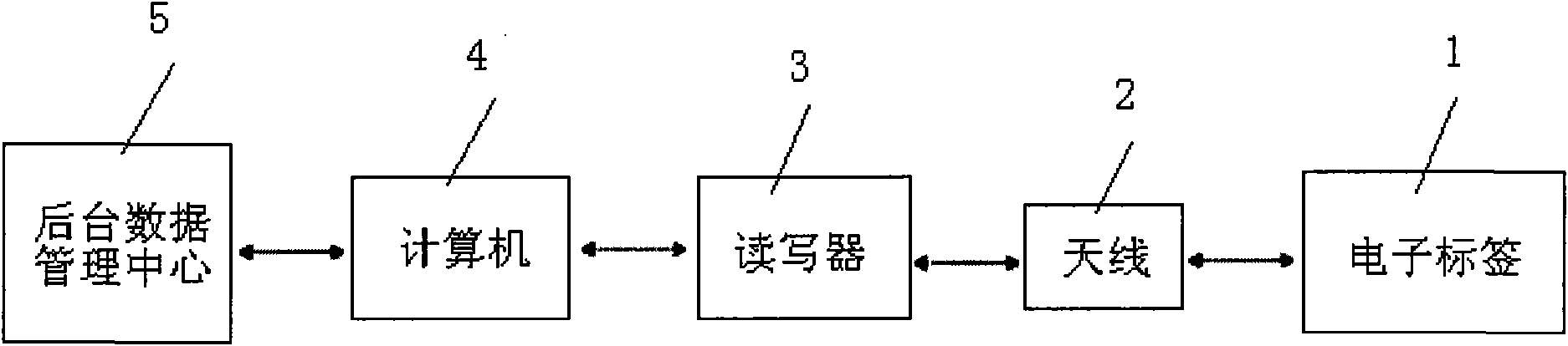

[0043] When the goods enter the warehouse, the reader 2 installed at the entrance of the warehouse automatically reads and recognizes the information on the goods labels 11 attached to the large packaging boxes of the goods, and the read label information is transmitted to the computer 4 through the data transmission network for preliminary processing. Processing, after confirmation by the goods warehousing software, the confirmation data will be automatically uploaded to the background data management center 5, and the goods will enter the warehouse at the same time.

Embodiment 2

[0044] Embodiment 2. Goods on-shelf management

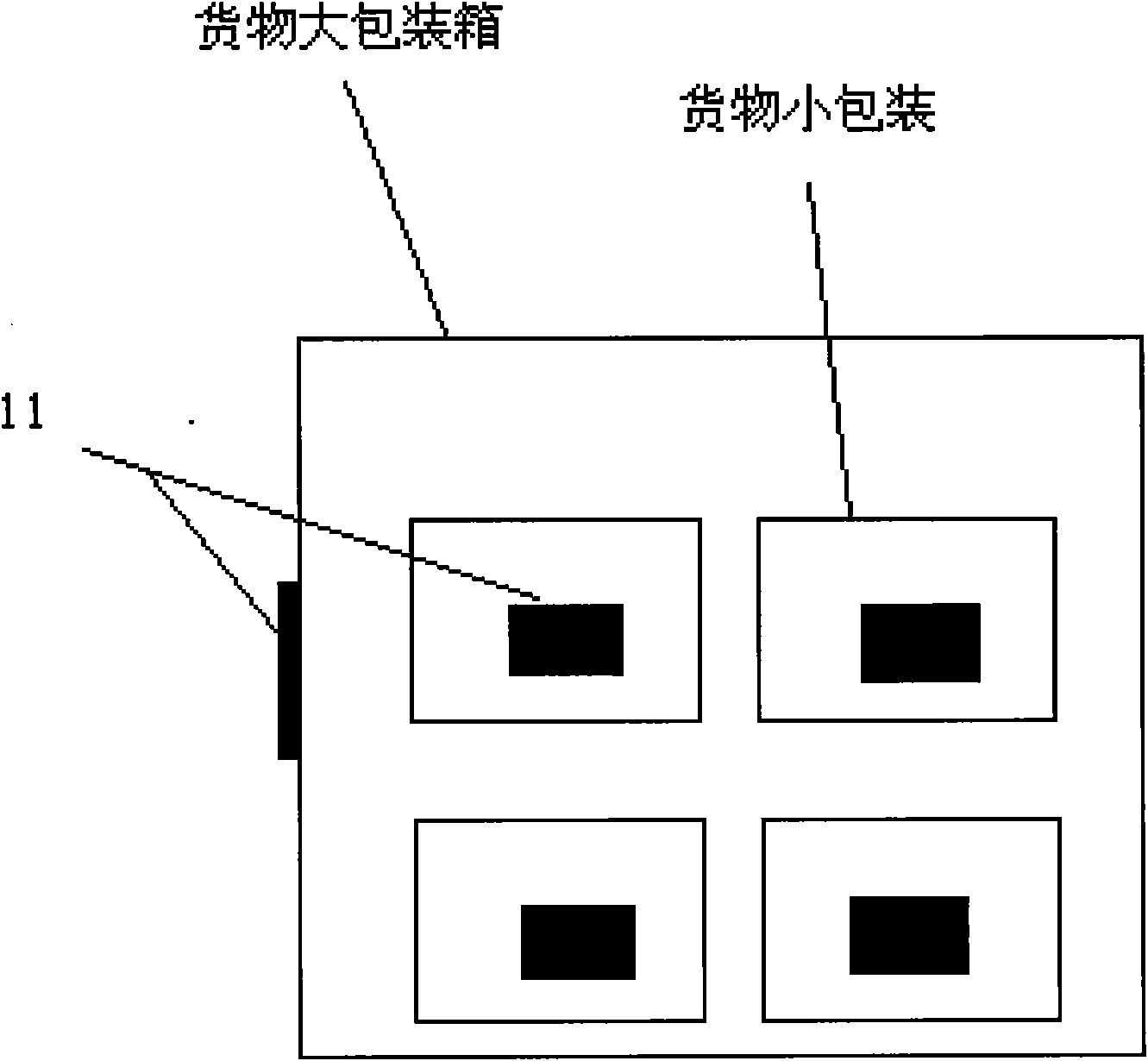

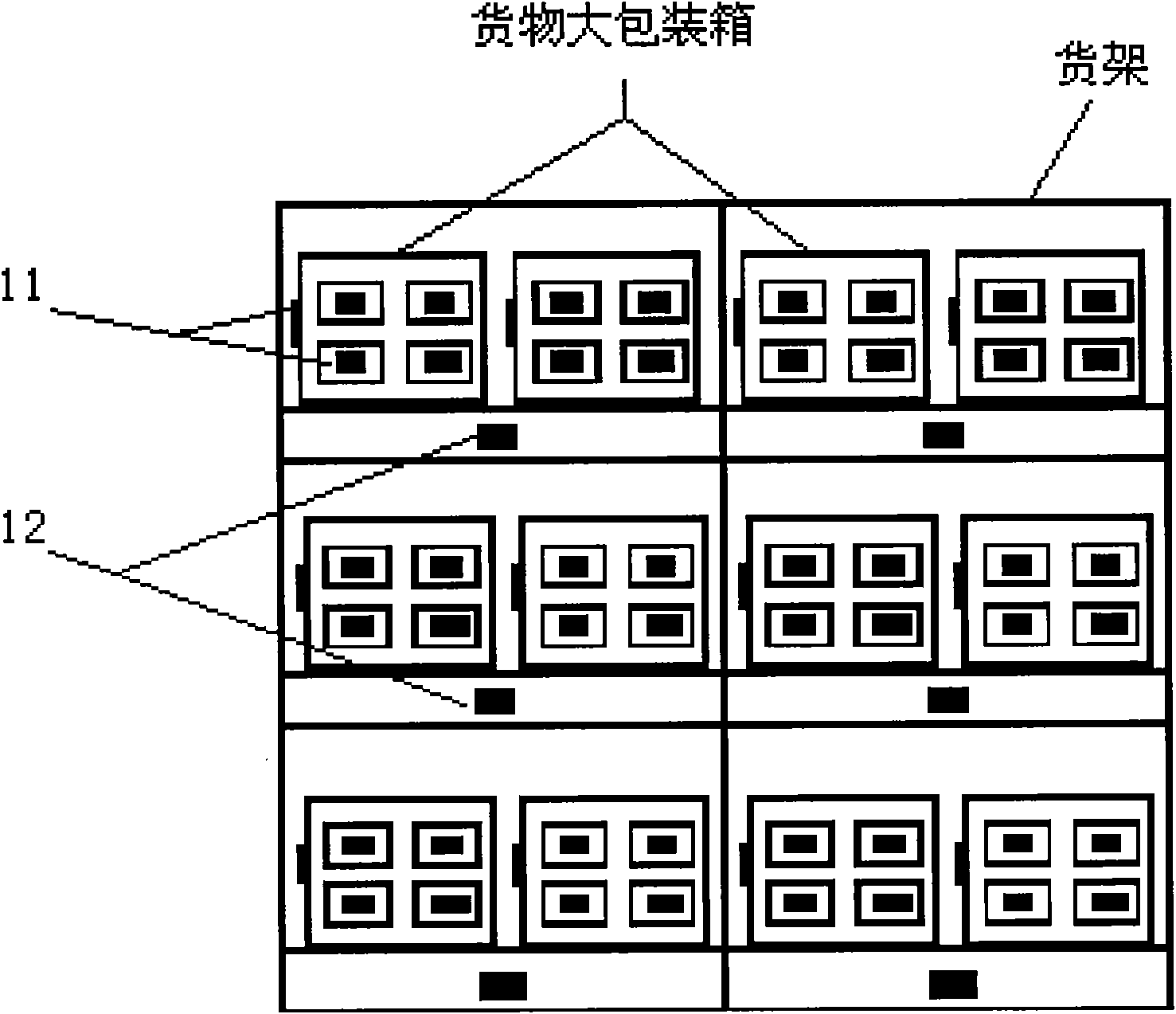

[0045] Before the goods are put on the shelf, the reader 2 installed on the forklift automatically reads and recognizes the information on the goods label 11 attached to the large box of the goods, and the read information is sent to the background data management center 5 in time after preliminary processing by the computer 4 , the background data management center 5 assigns the cargo location number according to the specific conditions of the cargo. When the forklift is placing the goods, the reader 2 reads the location label 12 attached to the shelf, and the read location information is sent to the computer 4, and compared with the location number assigned by the background data management center, if it is correct, then Place the goods in this location.

Embodiment 3

[0046] Embodiment 3. Cargo Sorting Management

[0047] When the goods are sorted, the computer 4 calls the goods information and location information of the goods to be sorted from the background data management center 5 to determine the sorting line, and the fixed reader or handheld reader 2 installed near the sorting line Carry out automatic information reading and identification on the goods label 11 or the location label 12 of the sorted goods, and transmit the read information to the computer 4, and the computer 4 processes the sorting confirmation information of the goods in time, and the confirmation data will be automatically uploaded to the background data Management Center5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com