Cleaning method of grinded silicon wafer

A silicon wafer cleaning and pre-cleaning technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems affecting the service life of the cleaning machine, wasted thickness of silicon wafer raw materials, and short cleaning life, so as to save manufacturing costs. As well as the later detection and maintenance costs, reducing the harm of ultrasound to the human body, and improving the effect of cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

[0034] The present invention will be described in detail below in conjunction with examples.

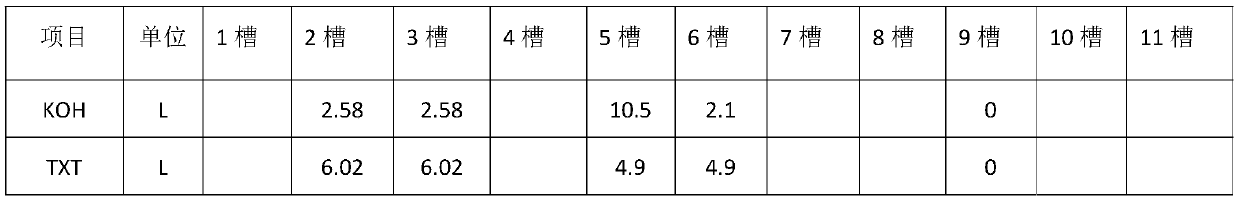

[0035] The purpose of this process is to remove impurities such as corundum, silicon powder, silicon oxide, and metal oxide remaining on the surface of the ground silicon wafer.

[0036] It includes pre-cleaning and cleaning steps in sequence, wherein the pre-cleaning sequentially includes bubbling, pre-cleaning solution cleaning and pure water cleaning; cleaning includes ultrasonic cleaning and pure water cleaning, wherein ultrasonic cleaning and pure water cleaning Alternate several times....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com