Armrest apparatus

A technology of handrails and rolls, which is applied in the directions of handrails, transportation and packaging, special positions of vehicles, etc., can solve problems such as troublesome operation, and achieve the effects of easy production, size reduction and weight reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

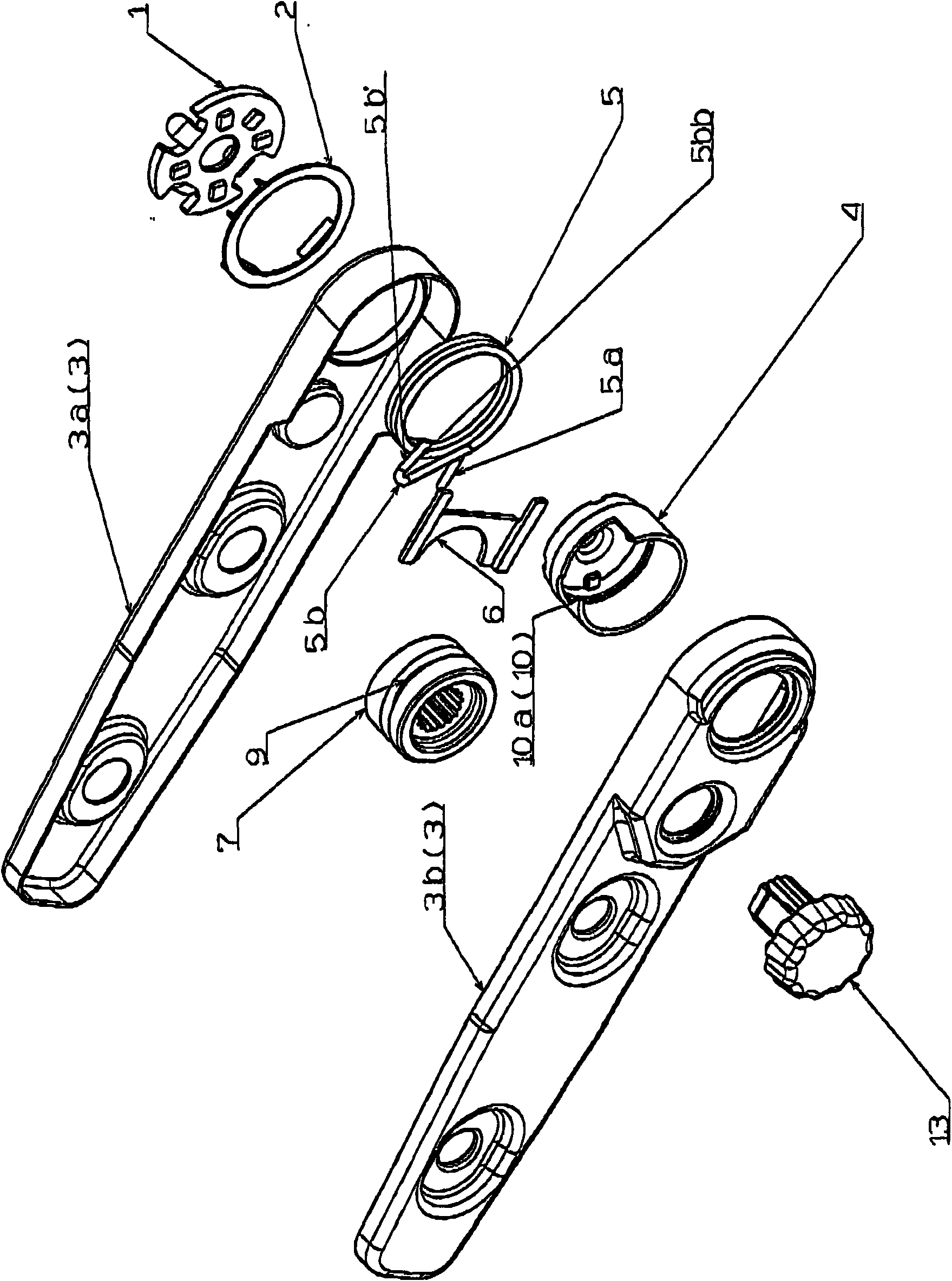

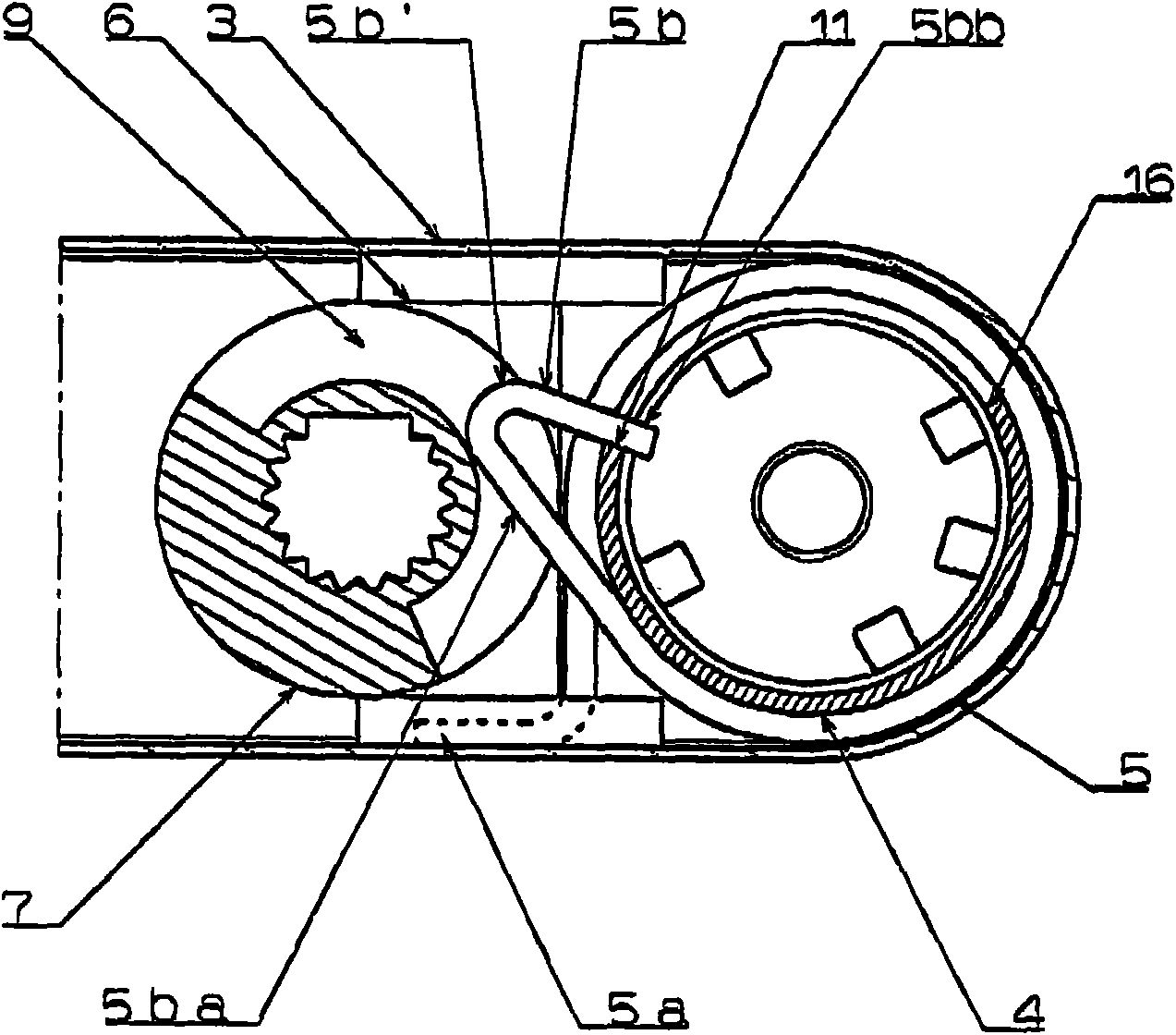

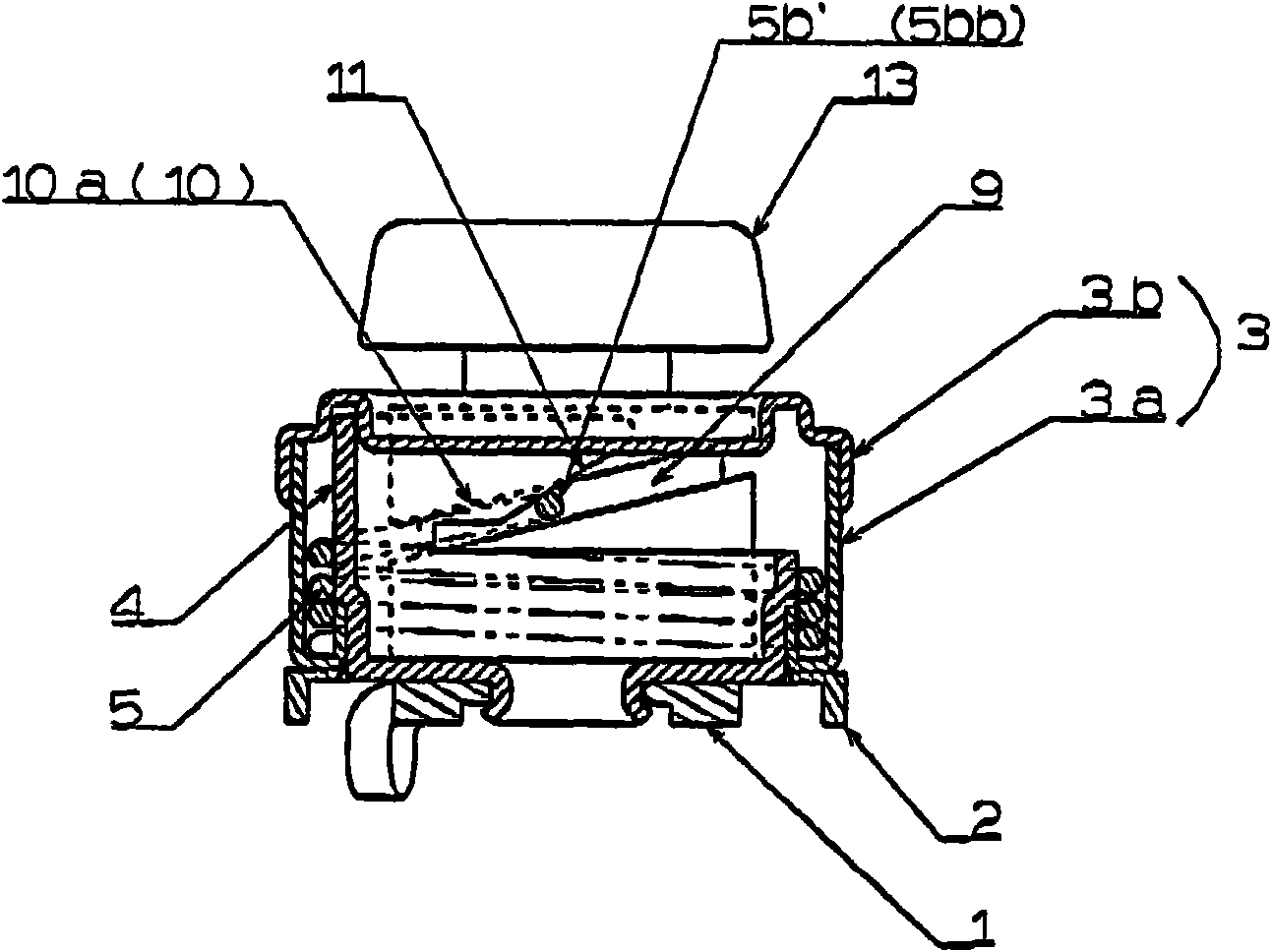

[0018] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is an exploded perspective view of the armrest device of the present invention, figure 2 is a longitudinal sectional view of the main part, image 3 is a transverse sectional view of the main part, Figure 4 It is an expanded view of a part of the reel with the support surface formed on the reel side, and the armrest device is composed of a mounting piece 1, a washer 2, a combined half arm 3a, a reel 4, a coil spring 5, a housing 3b, a reinforcing body 6, and an operating part 7 and operation button 13, etc., the mounting part 1 is fixed on the seat frame from the side of the seat frame (not shown), the combined half arm 3a constitutes the arm 3, and the reel 4 is fixed to the mounting part 1 through the washer 2 In this coil spring 5, one end is fixed on the combined half-arm 3a to form a fixed end 5a, and the other end forms a free end 5b, which is moved along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com