Process for treating spraying granulation aerosol smoke of fermentation waste liquor and dregs in pharmaceutical industry

A technology for fermentation waste liquid and shotcrete granulation, which is applied in the separation of dispersed particles, chemical instruments and methods, electrostatic effect separation, etc. The effect of operation and management, simple processing flow, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

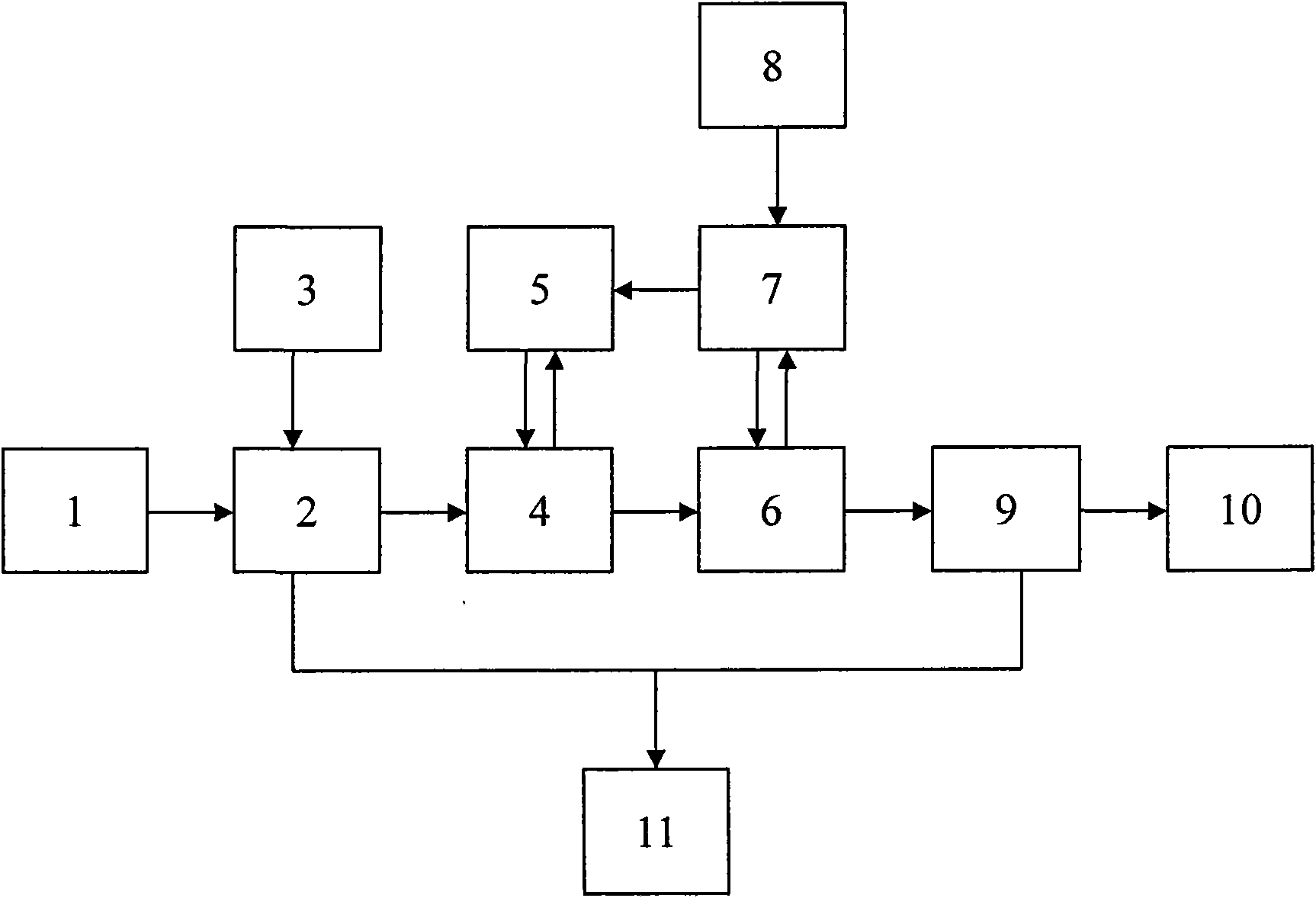

[0022] The aerosol flue gas 1 is firstly subjected to Venturi washing 2 by using the fermentation waste liquid 3; the washed flue gas is then subjected to the first-level spray washing 4 by using the water in the first-level spray circulation storage tank 5, and the water lost by the circulation washing Supplemented by the secondary circulation washing storage tank 7; after the primary spray washing, continue to use the water in the secondary circulation washing storage tank 7 to carry out the secondary spray washing 6, and the water lost by the secondary spray washing is taken from the clear water pool 8 Supplement; the aerosol flue gas enters the electrostatic processor for treatment 9 after three-stage washing; a clean gas 10 is formed; finally, the organic solution captured by the electrostatic treatment 9 and the washing waste that uses the fermentation waste liquid 3 to pass through the Venturi washing 2 The liquid is returned to the concentrated production process 11 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com