Method and device for improving operating efficiency of material handling equipment of bell type furnace units of steel enterprises

A technology of equipment operation and bell furnace, applied in the field of metallurgical information, can solve problems such as inability to grasp the overall situation, lack of rationality and scientificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0151] Embodiment 1: The initial state is the case where all resources are in an idle state

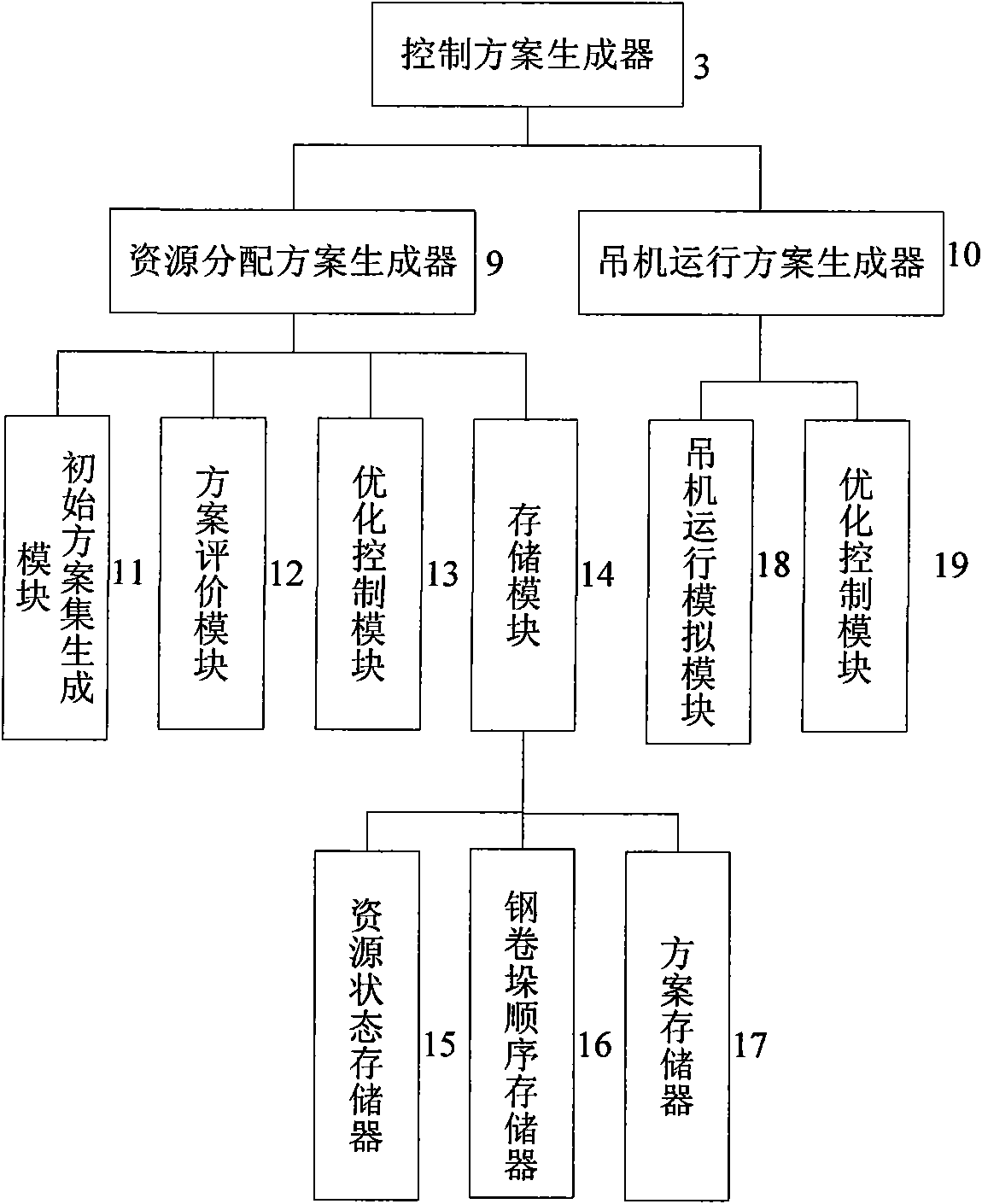

[0152] Figure 10 An example of a resource allocation plan for 3 stacks of steel coils to be processed, 3 hearths, 2 heating mantles, 1 cooling mantle, and 1 crane is given. After seeing the description of the following embodiments, it will be no problem for those skilled in the art to generalize to any number of steel coil stacks, hearths, heating mantles and cranes.

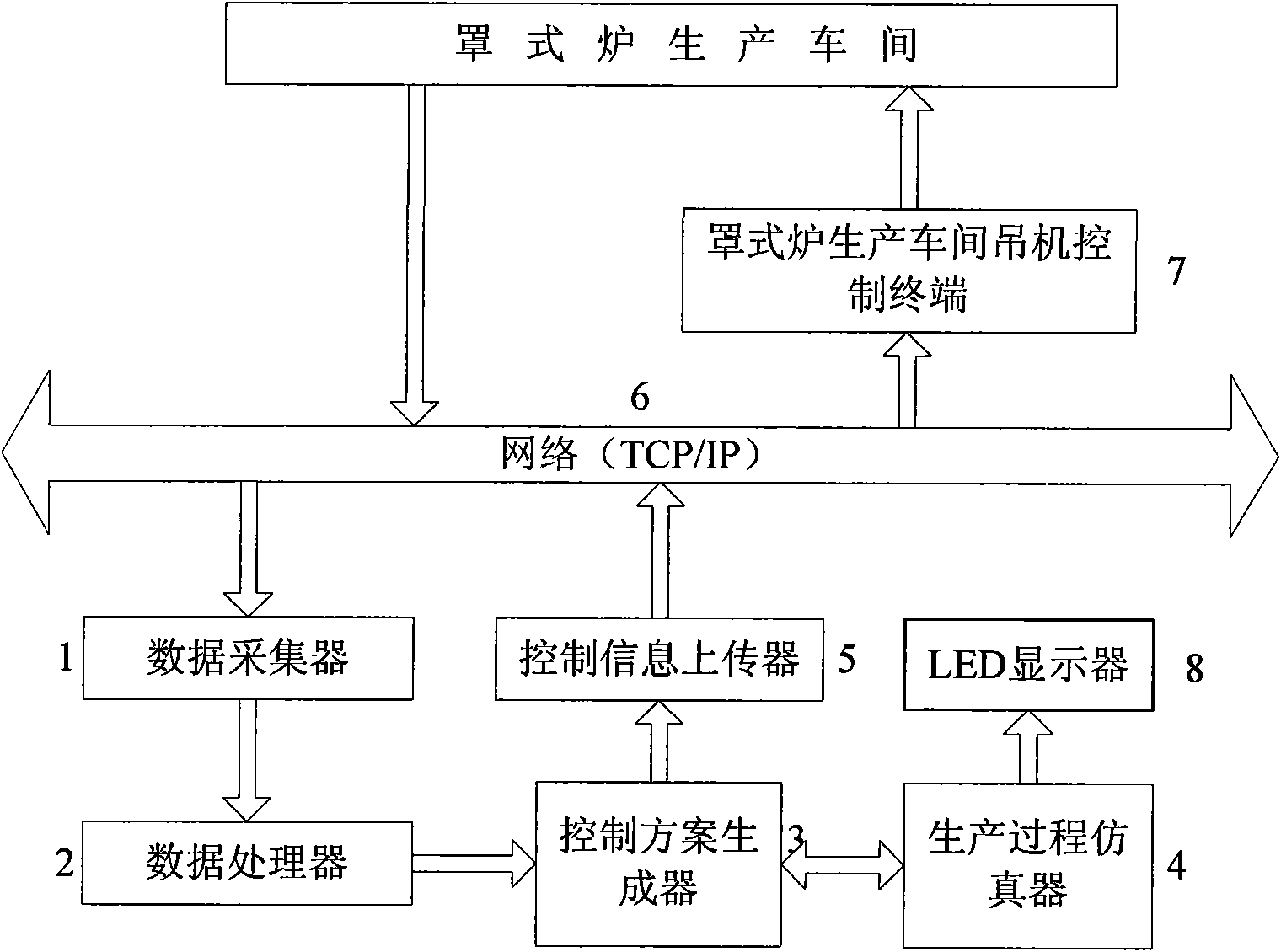

[0153] Step 1: When the steel coil stack information to be processed reaches the site, run the data collector 1 to collect real-time steel coil stacks and the occupancy of resources such as the hearth, heating mantle, cooling mantle, and crane in the bell-type furnace workshop, and transmit the collected information to to data processor 2;

[0154] The second step: according to the actual production situation, the input information can be analyzed in depth according to the data processor 2, and the processing time of...

Embodiment 2

[0177] Example 2: The initial state is the case where there is no idle stove available

[0178] When the steel coils to be processed are annealed, since there is no idle furnace base available, there is no idle furnace base available during the furnace loading stage. At this time, the steel coil needs to enter the stage of waiting for the furnace base. In order to shorten this waiting time, the resource allocation plan generator selects the earliest released furnace base allocation Stack the steel coils to meet the annealing requirements of the steel coils. , if multiple hearths are released at the same time, they will be allocated according to the principle of proximity, and if there is a situation where steel coil stacks compete for resources, they will be allocated in the order of steel coil stacks. Its specific implementation is the same as that of Example 1, and will not be repeated here.

Embodiment 3

[0179] Example 3: The initial state is the situation where no idle heating mantle is available

[0180] Since there is no idle heating mantle available, when the steel coil stack enters the heating mantle deduction stage, there may be no idle heating mantle available. At this time, the steel coil stack enters the waiting heating mantle stage, and the resource allocation plan generator selects the earliest released heating mantle Assigned to the steel coil stack to meet the requirements of steel coil annealing. If multiple heating mantles are released at the same time, they will be distributed according to the principle of proximity. In the event of steel coil stacks vying for resources, they will be allocated in the order of steel coil stacks. Its specific implementation is the same as that of Example 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com