Spherical Bi3O4Cl/BiOCl (bismuth-based oxychloride/bismuth oxychloride) visible light catalyst and preparation method thereof

A photocatalyst and catalyst technology, used in physical/chemical process catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of complicated preparation steps and high energy consumption, and achieve good repeatability and product yield. High efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Bi 3 o 4 The preparation steps of Cl / BiOCl photocatalyst are:

[0023] Step 1: Add bismuth nitrate pentahydrate and sodium chloride of 2:1 molar ratio in the mixed solution of 10ml of ethylene glycol and 5g of polyvinylpyrrolidone (PVP), wherein 1g of bismuth nitrate pentahydrate is stirred at room temperature to nitric acid pentahydrate Bismuth and sodium chloride are completely dissolved;

[0024] Step 2: Use Na(CO 3 ) 2 Adjust the pH value of the above solution to 6, and stir at room temperature for 30 minutes;

[0025] Step 3: Add the product of step 2 and 0.5g of urea into a 100ml hydrothermal reactor, and react at 140°C for 6h;

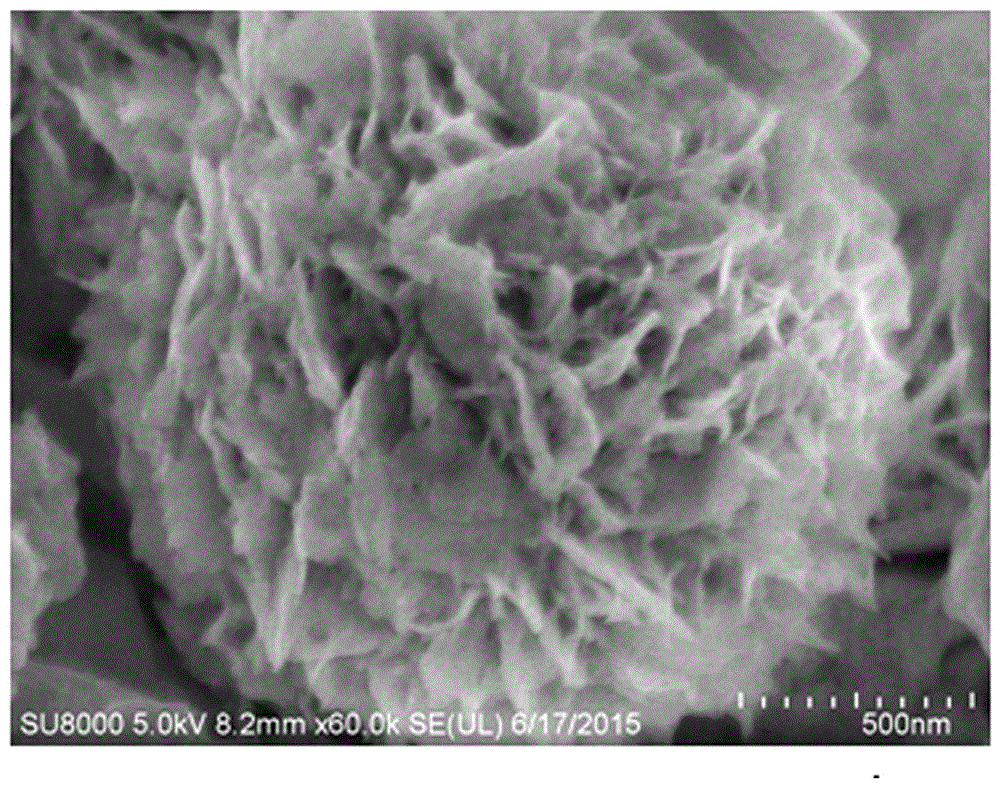

[0026] Step 4: After step 3, after centrifugal filtration, wash with distilled water and absolute ethanol three times respectively, and dry at 120°C for 12 hours to obtain Bi 3 o 4 Cl / BiOCl photocatalyst, the catalyst is a microsphere with a diameter of 1-2 μm.

Embodiment 2

[0028] Bi 3 o 4 The preparation steps of Cl / BiOCl photocatalyst are:

[0029] Step 1: Add bismuth nitrate pentahydrate and sodium chloride at a molar ratio of 3:2 in the mixed solution of 10ml of ethylene glycol and 5g of polyvinylpyrrolidone (PVP), wherein 1g of bismuth nitrate pentahydrate is stirred at room temperature until nitric acid pentahydrate Bismuth and sodium chloride are completely dissolved;

[0030] Step 2: Use Na(CO 3 ) 2 Adjust the pH value of the above solution to 6, and stir at room temperature for 30 minutes;

[0031] Step 3: Add the product of step 2 and 0.5g of urea into a 100ml hydrothermal reactor, and react at 140°C for 6h;

[0032] Step 4: After step 3, after centrifugal filtration, wash with distilled water and absolute ethanol three times respectively, and dry at 120°C for 12 hours to obtain Bi 3 o 4 Cl / BiOCl photocatalyst, the catalyst is a microsphere with a diameter of 1-2 μm.

Embodiment 3

[0034] Bi 3 o 4 The preparation steps of Cl / BiOCl photocatalyst are:

[0035] Step 1: Add bismuth nitrate pentahydrate and sodium chloride in a molar ratio of 5:2 to 10ml of ethylene glycol and 5g of polyvinylpyrrolidone (PVP) mixed solution, wherein 1g of bismuth nitrate pentahydrate, stir at room temperature until the pentahydrate Bismuth nitrate and sodium chloride are completely dissolved;

[0036] Step 2: Use Na(CO 3 ) 2 Adjust the pH value of the above solution to 6, and stir at room temperature for 30 minutes;

[0037] Step 3: Add the product of step 2 and 0.5g of urea into a 100ml hydrothermal reactor, and react at 140°C for 6h;

[0038] Step 4: After step 3, after centrifugal filtration, wash with distilled water and absolute ethanol three times respectively, and dry at 120°C for 12 hours to obtain Bi 3 o 4 Cl / BiOCl photocatalyst, the catalyst is a microsphere with a diameter of 1-2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com