Preparation and application of CeVO4/BiVO4 heterojunction with visible-light response

A heterojunction and microsphere technology, applied in the fields of light water/sewage treatment, chemical/physical process, water/sludge/sewage treatment, etc., can solve the problems of BiVO4 photocatalytic application limitation and other problems, and achieve the effect of easy industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] CaVO 4 / BiVO 4 The preparation steps of the heterojunction are:

[0031] Step 1, 0.001mol cerium nitrate Ce (NO 3 ) 3 ·6H 2 O and 0.002mol cerium nitrate Bi(NO 3 ) 3 ·5H 2 O was added to 20ml ethylene glycol solution, and magnetically stirred until dissolved;

[0032] Step 2, 0.015mol ammonium metavanadate NH 4 VO 3 Add to 25ml of distilled water at 50°C, stir magnetically until dissolved;

[0033] Step 3. Slowly drop the product of step 2 into the mixed solution of step 1, adjust the pH of the solution to 1, and sonicate at room temperature for 30 minutes;

[0034] Step 4: Add the product of Step 3 into a 100ml hydrothermal reactor, and react at a reaction temperature of 100°C for 4h.

[0035] Step 5: After step 4 is completed, filter, wash with distilled water and absolute ethanol respectively, then dry the product at 120°C for 12h, and then roast at 200°C for 5h.

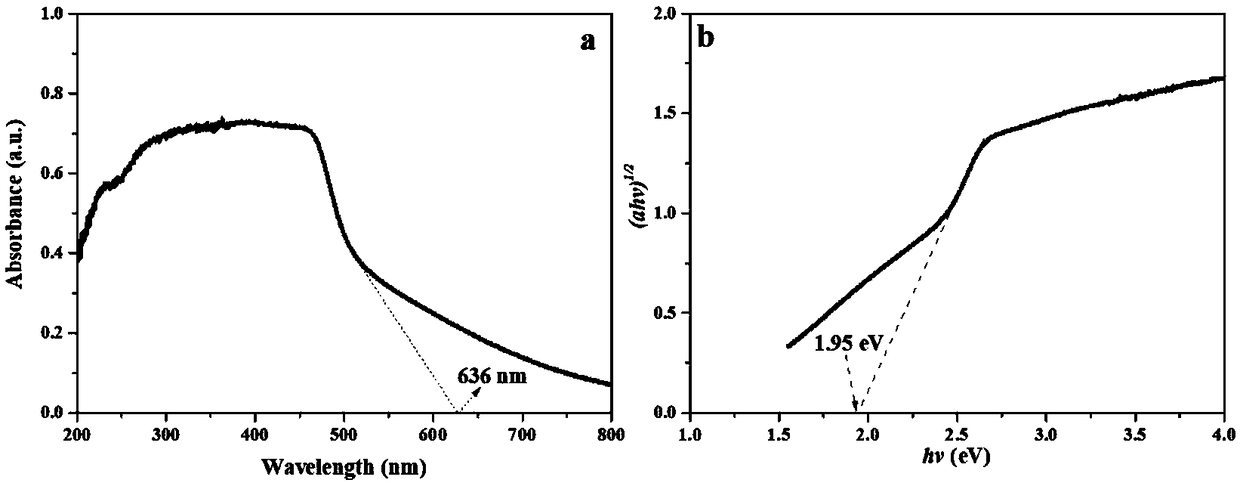

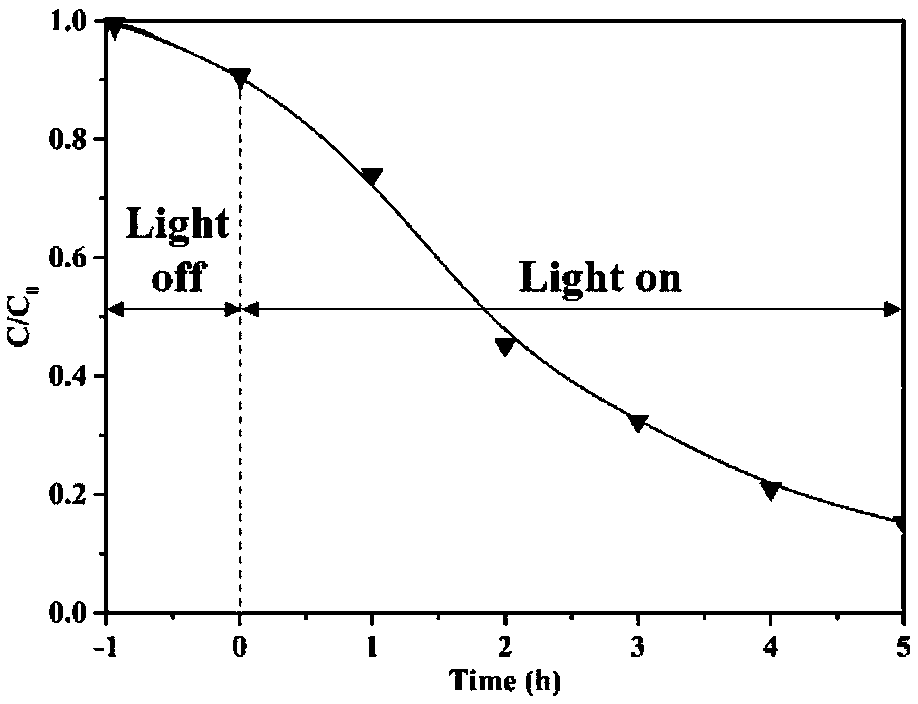

[0036] From figure 1 It can be seen that the prepared CeVO 4 / BiVO 4 heterojunction, wh...

Embodiment 2

[0039] CaVO 4 / BiVO 4 The preparation steps of the heterojunction are:

[0040] Step 1, 0.001mol cerium nitrate Ce (NO 3 ) 3 ·6H 2 O and 0.01mol cerium nitrate Bi(NO 3 )3 ·5H 2 O was added to 65ml of glycerin solution, magnetically stirred until dissolved;

[0041] Step 2, 0.011mol ammonium metavanadate NH 4 VO 3 Add to 15ml of distilled water at 100°C, stir magnetically until dissolved;

[0042] Step 3. Slowly drop the product of step 2 into the mixed solution of step 1, adjust the pH of the solution to 6, and sonicate at room temperature for 120 minutes;

[0043] Step 4: Add the product of Step 3 into a 100ml hydrothermal reactor, and react at a reaction temperature of 200°C for 2h.

[0044] Step 5: After step 4 is completed, filter, wash with distilled water and absolute ethanol respectively, then dry the product at 120°C for 12h, and calcinate at 500°C for 1h.

Embodiment 3

[0046] CaVO 4 / BiVO 4 The preparation steps of the heterojunction are:

[0047] Step 1, 0.001mol cerium nitrate Ce (NO 3 ) 3 ·6H 2 O and 0.002mol cerium nitrate Bi(NO 3 ) 3 ·5H 2 O was added to 30ml propanol solution, and magnetically stirred until dissolved;

[0048] Step 2, 0.015mol ammonium metavanadate NH 4 VO 3 Add to 25ml of distilled water at 50°C, stir magnetically until dissolved;

[0049] Step 3. Slowly drop the product of step 2 into the mixed solution of step 1, adjust the pH of the solution to 1, and sonicate at room temperature for 30 minutes;

[0050] Step 4: Add the product of Step 3 into a 100ml hydrothermal reactor, and react at a reaction temperature of 100°C for 4h.

[0051] Step 5: After step 4 is completed, filter, wash with distilled water and absolute ethanol respectively, then dry the product at 120°C for 12h, and then roast at 200°C for 5h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com