Independent pitch control method for large wind turbine

A technology of independently variable pitch and wind turbines, which is applied in the direction of wind motor combination, wind engine control, wind power generation, etc., and can solve the problems that the unbalanced load and fatigue load of the impeller cannot be effectively reduced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

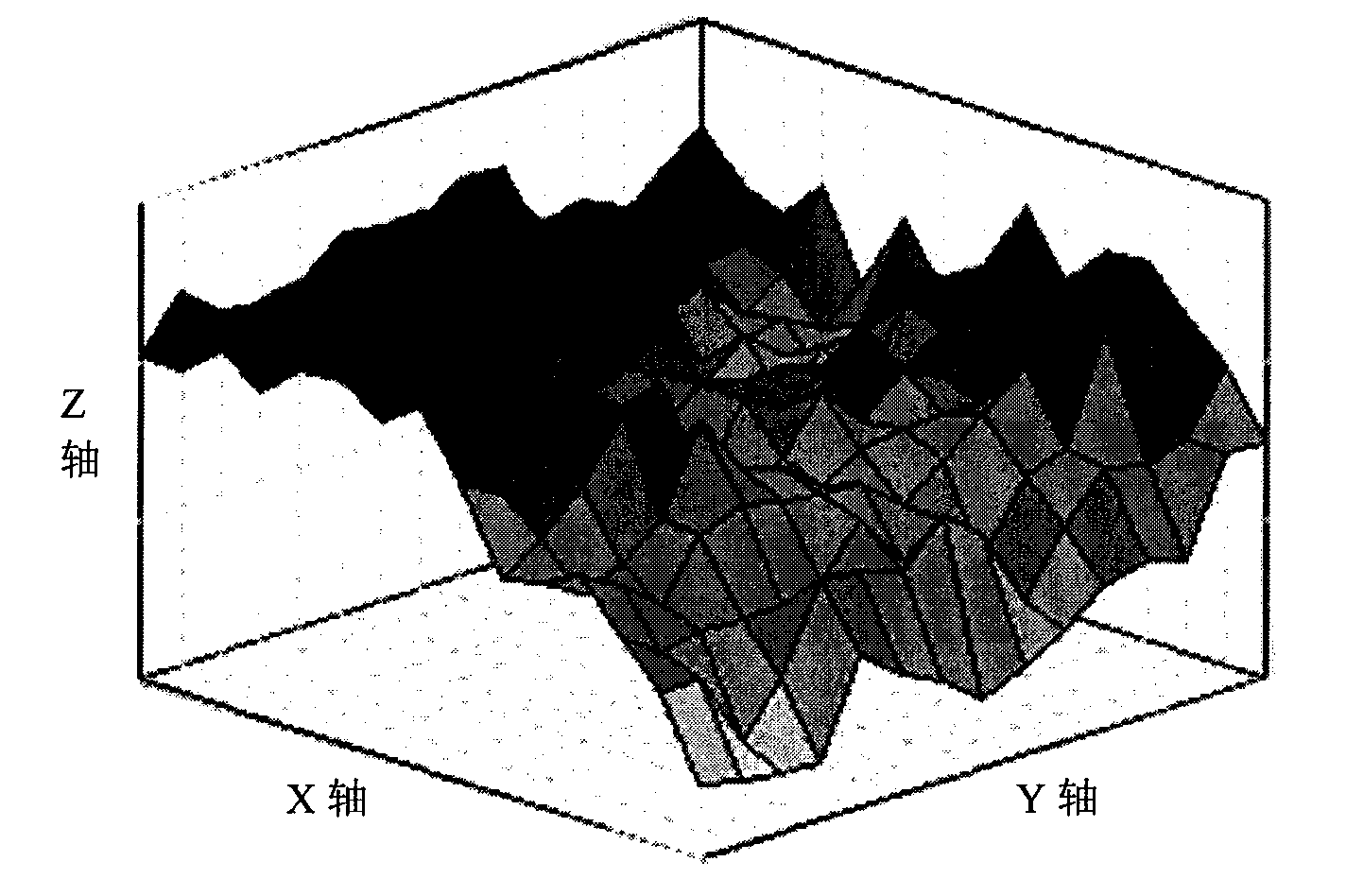

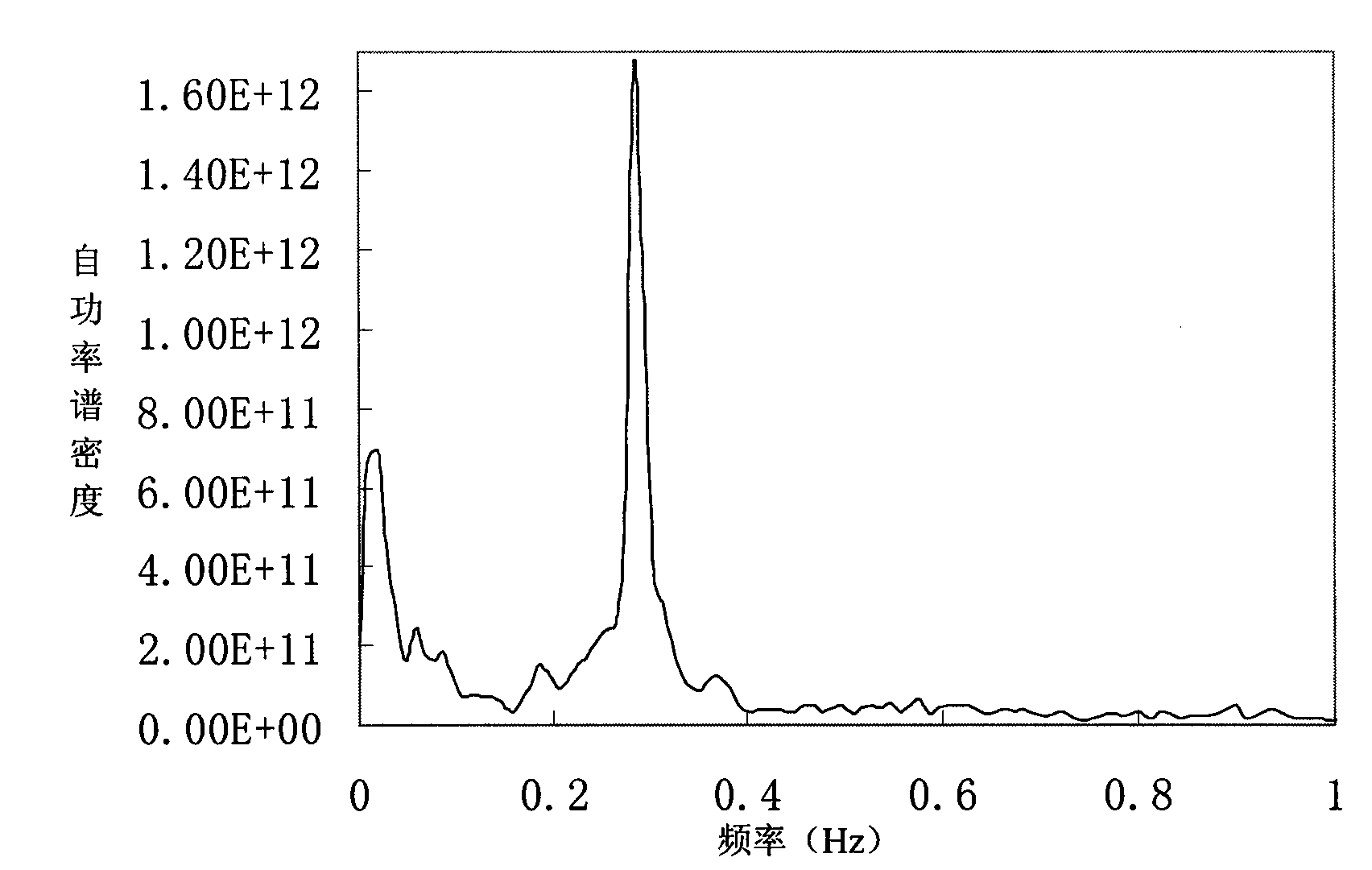

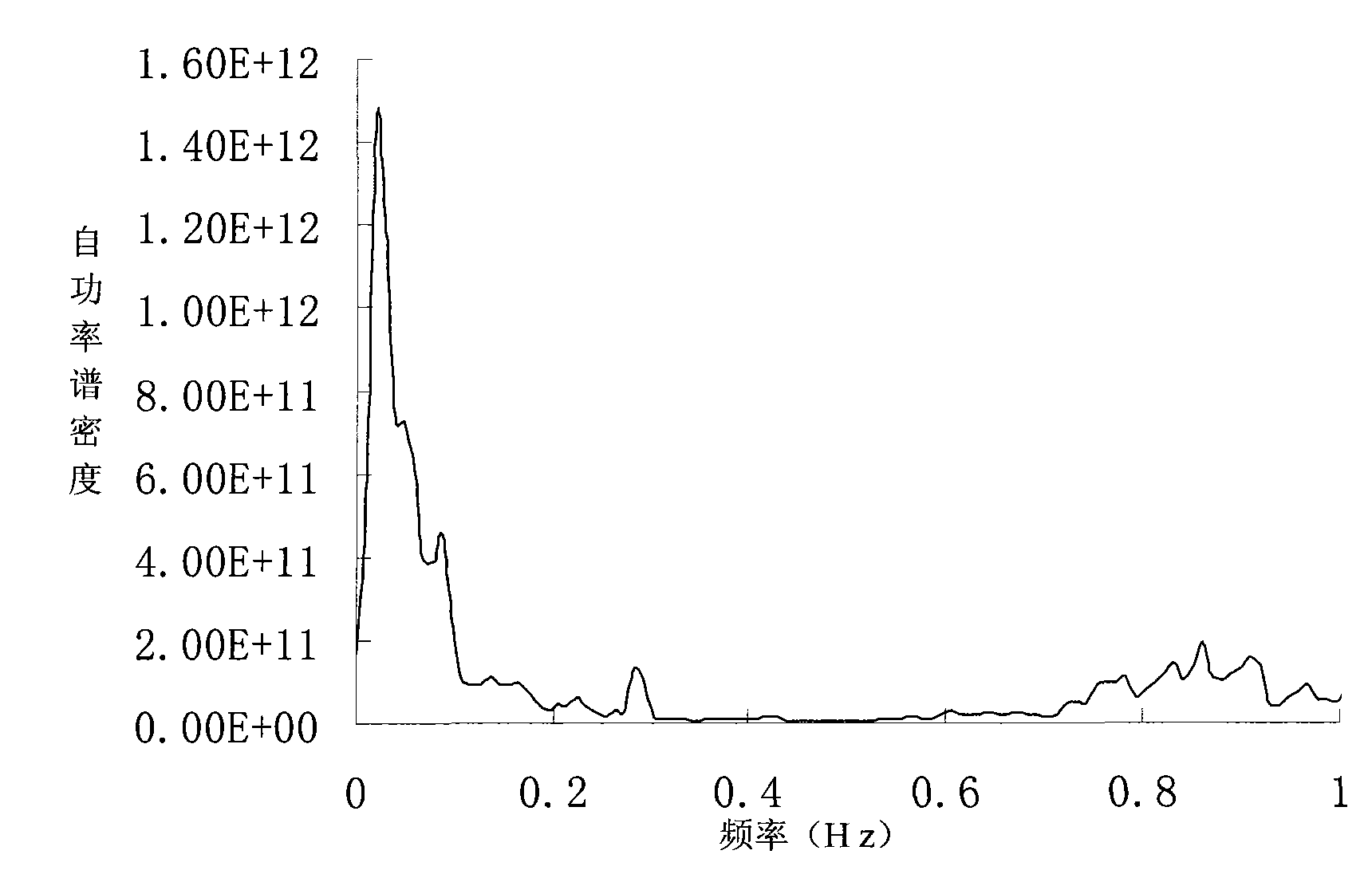

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] refer to Figure 1 to Figure 5 , a large-scale wind turbine independent pitch control method, including a coordinated pitch control process, the coordinated pitch control process is: detecting the generator speed ω g , and the reference speed ω ref The rotational speed deviation Δω is obtained by subtraction, and the cooperative pitch angle β of the expected output of cooperative pitching is obtained according to the following Laplace relation c : β c ( s ) Δω ( s ) = K c s T c ( ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com