Ultrathin steel-socket prestress longitudinal bar steel-fiber concrete pipe

A technology of steel fiber concrete and prestressed steel wire, applied to pipes, rigid pipes, pipes/pipe joints/pipe fittings, etc., can solve the problems of increasing the transportation cost and construction cost of concrete pipes, the weight of concrete pipes, and the high cost of raw materials. Good water-tightness of joints, thin tube core wall, and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

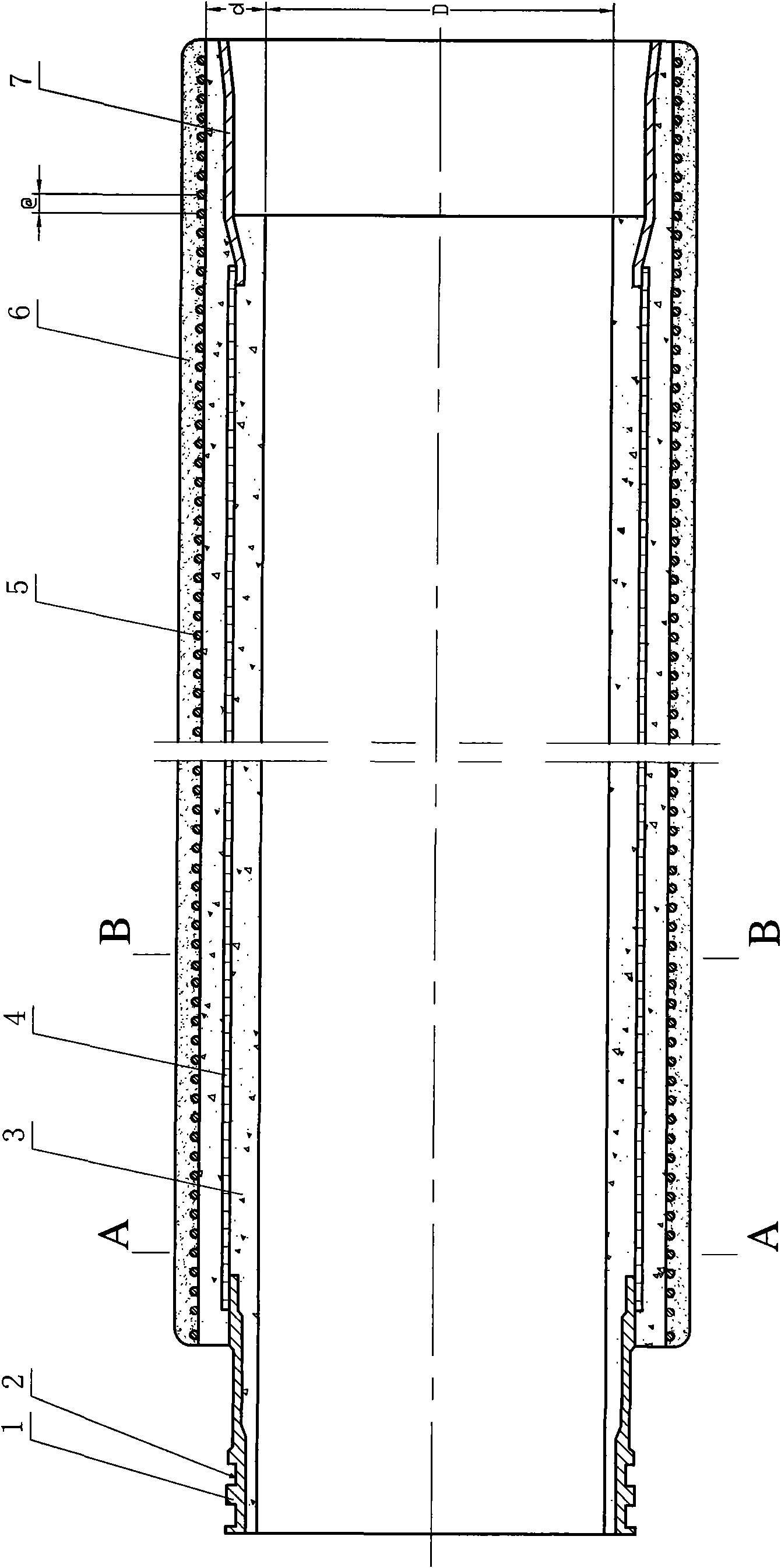

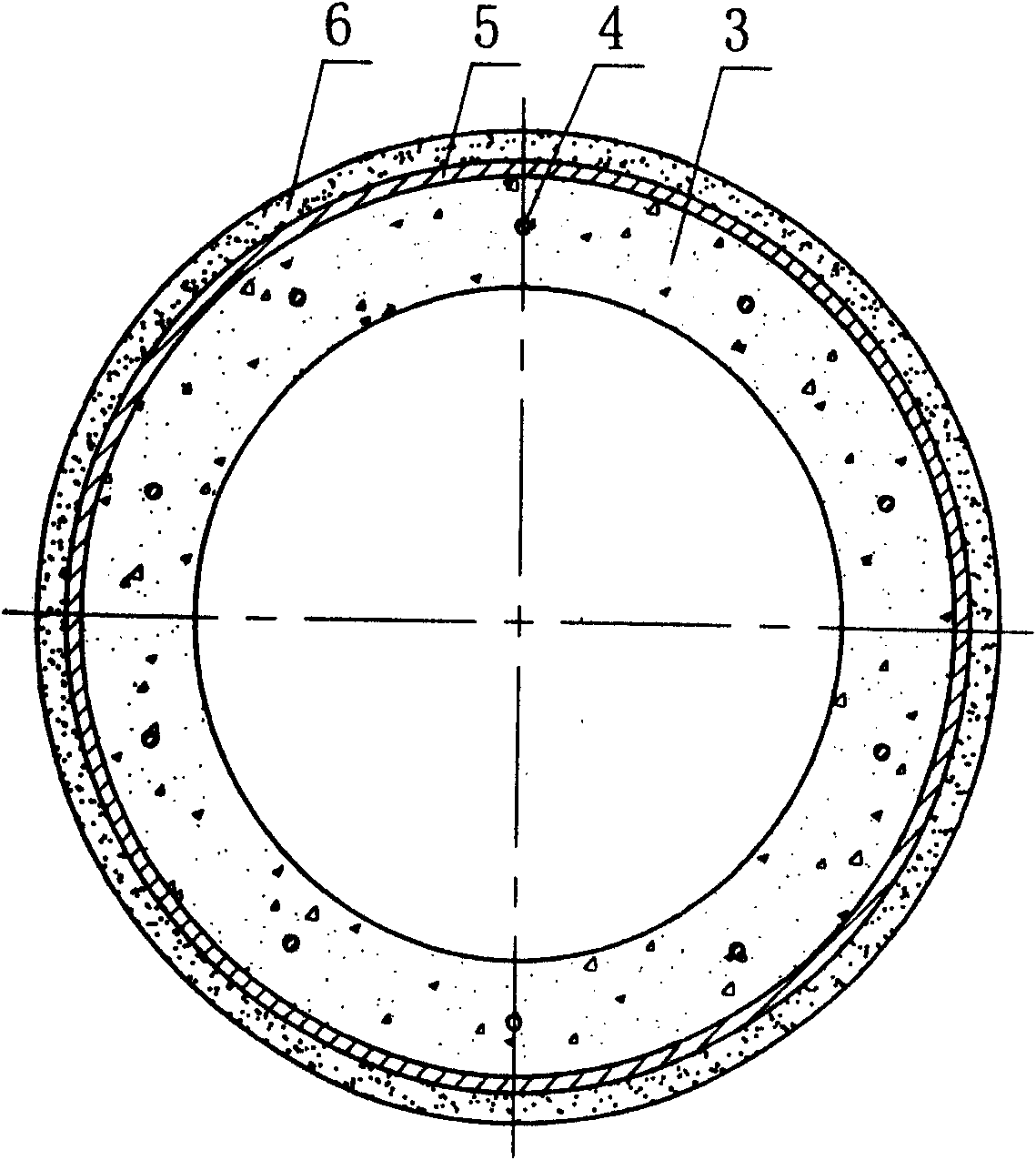

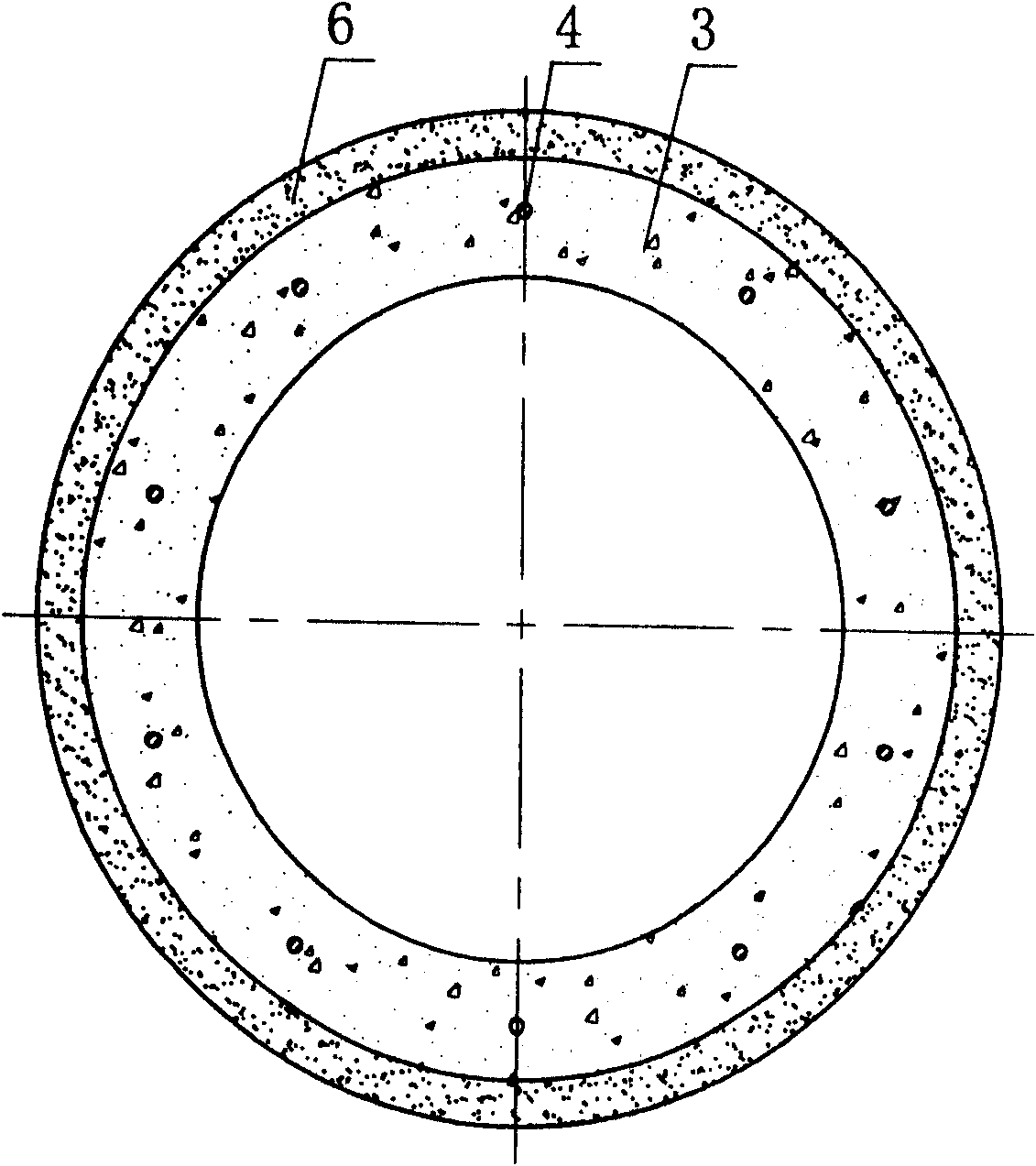

[0027] 1. Concrete pipe, pipe inner diameter D: 2000mm, pipe core wall thickness d: 40mm, prestressed steel wire diameter φ: 4mm, prestressed steel wire pitch @: 8mm.

[0028] 2. Concrete pipe, pipe inner diameter D: 2400mm, pipe core wall thickness d: 75mm, prestressed steel wire diameter φ: 6mm, prestressed steel wire pitch @: 18mm.

[0029] 3. Concrete pipe, pipe inner diameter D: 2600mm, pipe core wall thickness d: 50mm, prestressed steel wire diameter φ: 10mm, prestressed steel wire pitch @: 48mm.

[0030] The socket and socket of the invention is a flexible interface and has good water tightness, which can effectively ensure the tightness of the whole pipeline even in the case of foundation settlement, and prevent the leakage of sewage. Since the present invention adopts reinforced concrete structure, it can resist a considerable external pressure load, and the depth of soil covering during construction is small, which reduces construction difficulty and construction cos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com