Polarized spectacle lens structure and manufacturing method thereof

A technology of optical glasses and lenses, applied in glasses/goggles, chemical instruments and methods, optics, etc., can solve problems such as poor temperature resistance, abrasion, easy rebound deformation, etc., achieves improved peeling resistance, simple production process, Optical performance stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

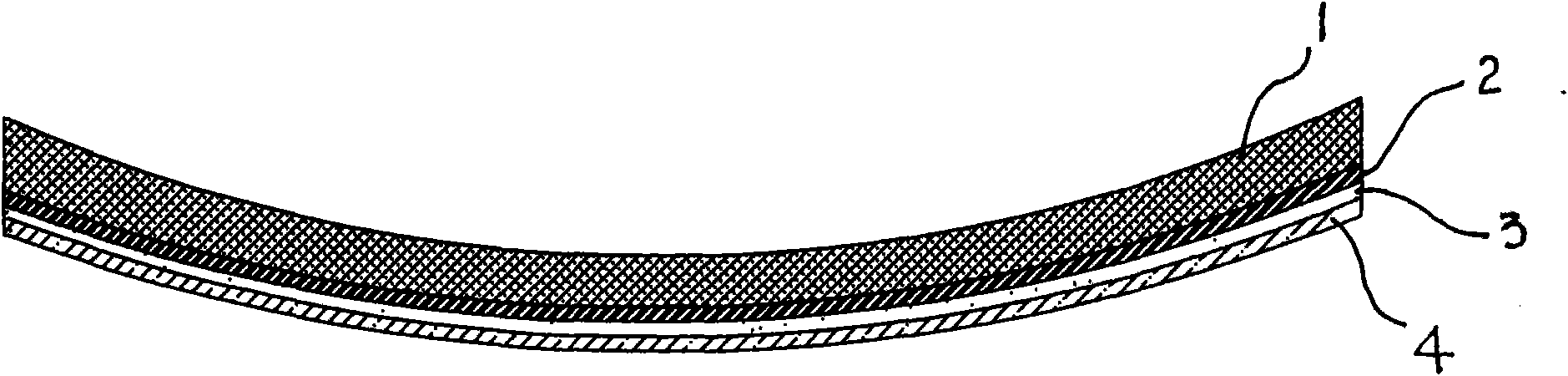

[0017] As shown in the figure, the present invention includes a thermoplastic resin lens layer 1 and a polarizing film combination, the polarizing film combination is composed of a bonding film layer 2, a polarizing film 3 and a protective film layer 4, and the bonding film layer 2 and the protective film layer 4 are bonded together. Agents are bonded on both sides of the polarizing film 3 respectively, and the bonding film layer 2 in the polarizing film combination is combined with the thermoplastic resin lens layer 1 through an injection molding process. The same resin material is used for the thermoplastic resin lens layer 1 and the bonding film layer 2. In the present invention, the thermoplastic resin lens layer 1 and the bonding film layer 2 are made of polycarbonate material, and the protective film layer 4 is made of triacetate fiber material. The concrete manufacturing process of the present invention is: 1, first stretch polyvinyl alcohol film and dye with dichroic dy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com