Through electromagnetic induction heating pipe structure

A technology of electromagnetic induction heating and induction heating coil, applied in induction heating, induction heating device, surface pretreatment, etc., can solve the problems of easy mutual adhesion of workpieces, affecting product quality, long drying time, etc. High quality and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

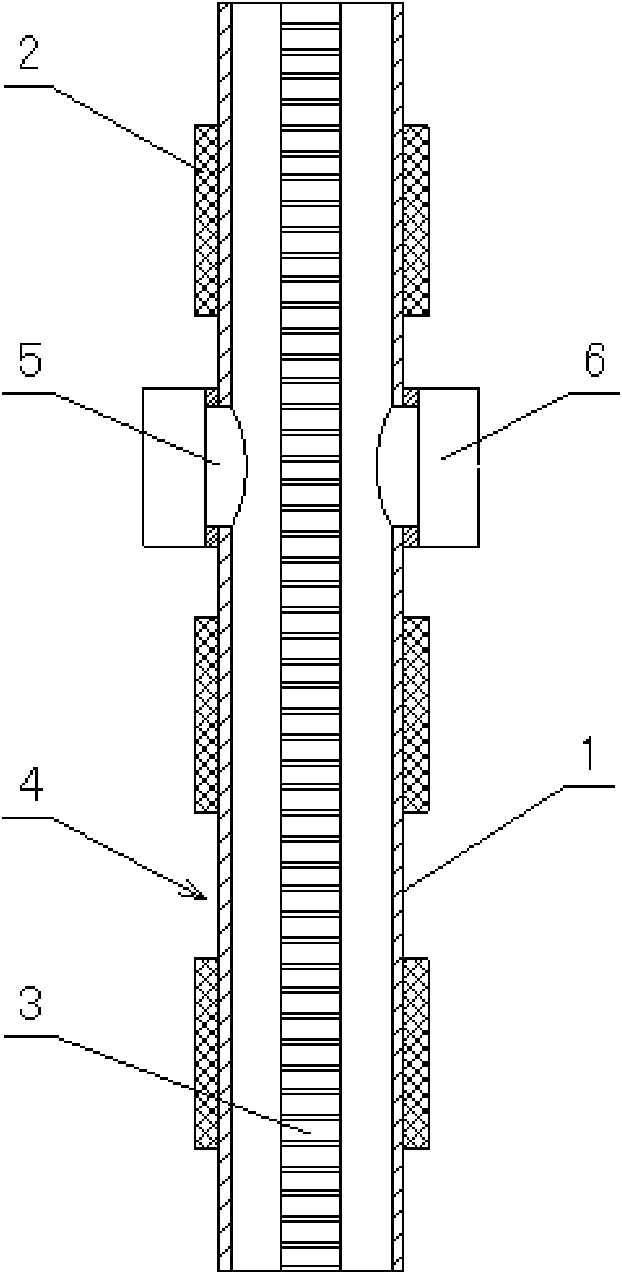

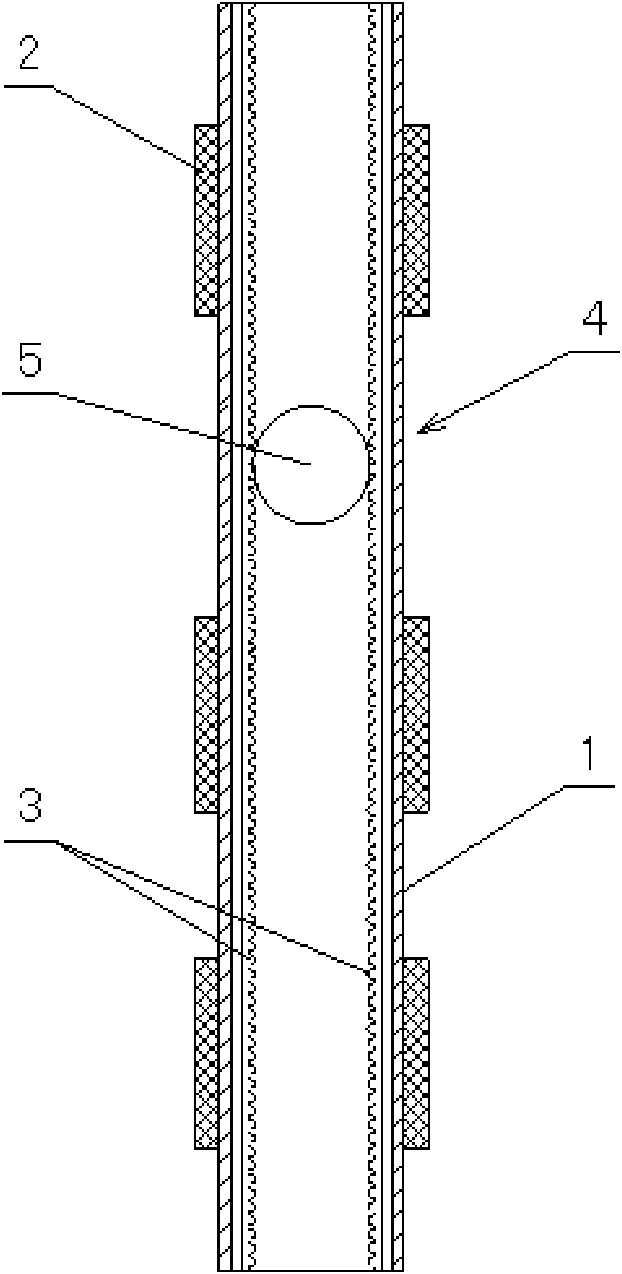

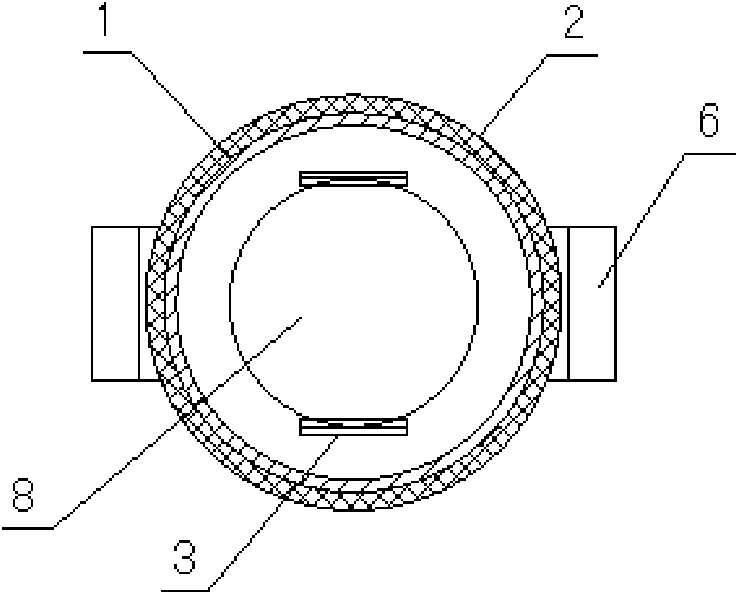

[0024] in such as figure 1 figure 2 In the shown embodiment 1, a through-type electromagnetic induction heating pipe structure includes a pipe body 1 and an induction heating coil 2 surrounding the periphery of the pipe body. The pipe body is arranged in a vertical state, and the inner cavity of the pipe body is horizontal. The cross-section is circular, suitable for circular workpieces, and the distance between the edge of the workpiece and the inner wall of the pipe is equal (see image 3); the body is provided with an induction heating coil, and there are 3 induction heating coils, which are arranged on the outer surface of the pipe body in sections, a buffer section 4 is provided between adjacent induction heating coils, and a buffer section of the pipe body is provided with There are two through holes 5, symmetrically arranged on both sides of the central axis of the pipe body, and a ventilation device 6 is arranged on the through hole, and the ventilation device is a f...

Embodiment 2

[0026] The cross-section of the inner cavity of the tube used in embodiment 2 is elliptical, which is compatible with the elliptical end workpiece, and the distance between the edge of the elliptical workpiece and the inner wall of the tube is equal (see Figure 4 ), the workpiece transmission device is two single-sided toothed synchronous belts, which are symmetrically arranged on the short side of the cross-section of the oval inner cavity of the pipe body. There is a partition 7 between them, and the tooth surface of the upward section of the single-sided toothed synchronous belt faces the center of the pipe body (see Figure 7 ), there are 4 induction heating coils, which are arranged on the outer surface of the pipe body, and the structure of the remaining pipe body parts is the same as that of embodiment 1.

Embodiment 3

[0028] Embodiment 3 The lumen cross-section of the pipe body is elliptical, and the length-to-short-side ratio of the lumen cross-section is greater than the length-to-short side ratio of the elliptical workpiece (see Figure 5 ), the workpiece transmission device is two double-sided toothed synchronous belts, which are symmetrically arranged in the direction of the short side of the inner cavity cross section. Separator, the structure of other pipe body parts is identical with embodiment 1.

[0029] When the through-type electromagnetic induction heating tube is working, the motor drives the synchronous belt arranged on the inner side of the tube body to move upward synchronously through the driving wheel 9, the driving wheel 10, and the driven wheel 11, and the iron sheet workpiece 8 such as the end cover passes through the lower part of the tube body. The inlet conveyor belt 12 at the port is transferred to the timing belt, and the workpiece is placed in the tooth grooves o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com