Hydraulic control circuit for construction machine

A technology of oil pressure control and construction machinery, applied in mechanical equipment, construction, servo meter circuits, etc., can solve problems such as poor workability and achieve good workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

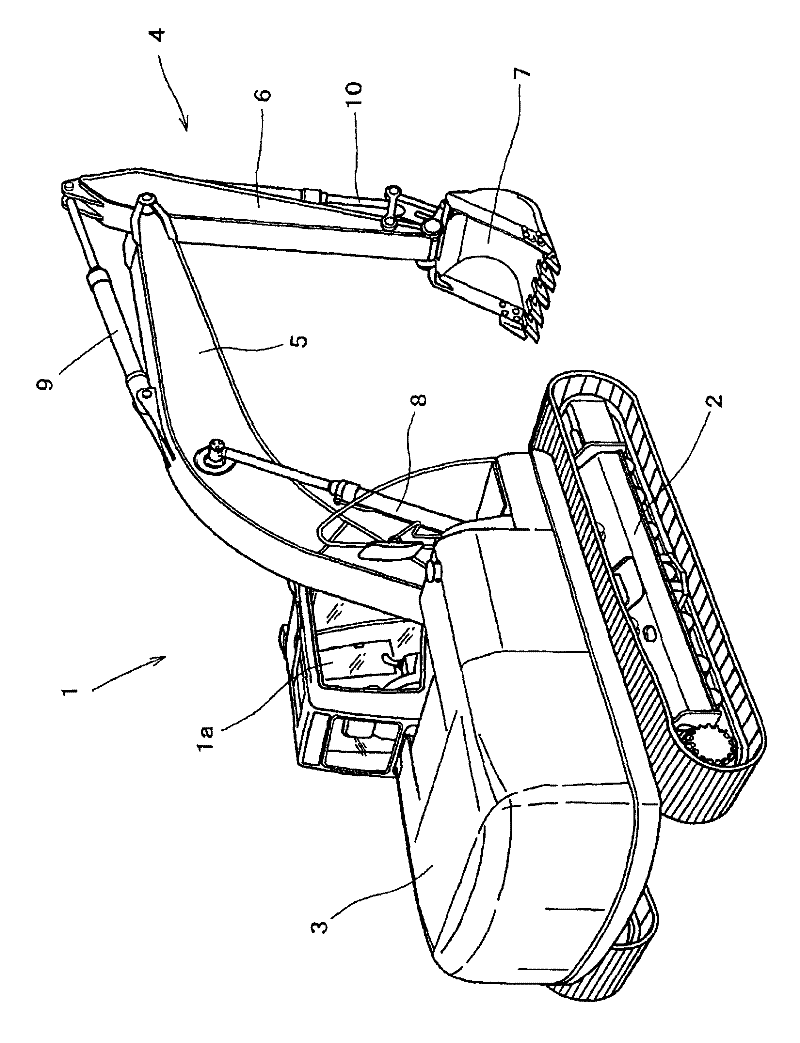

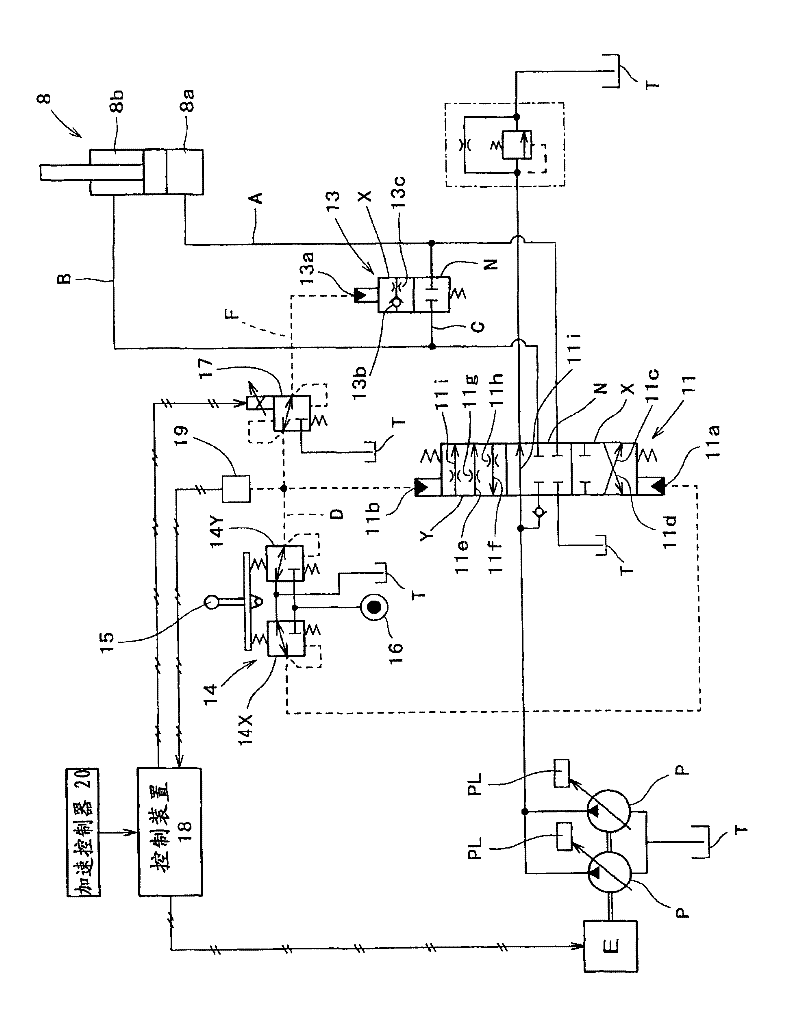

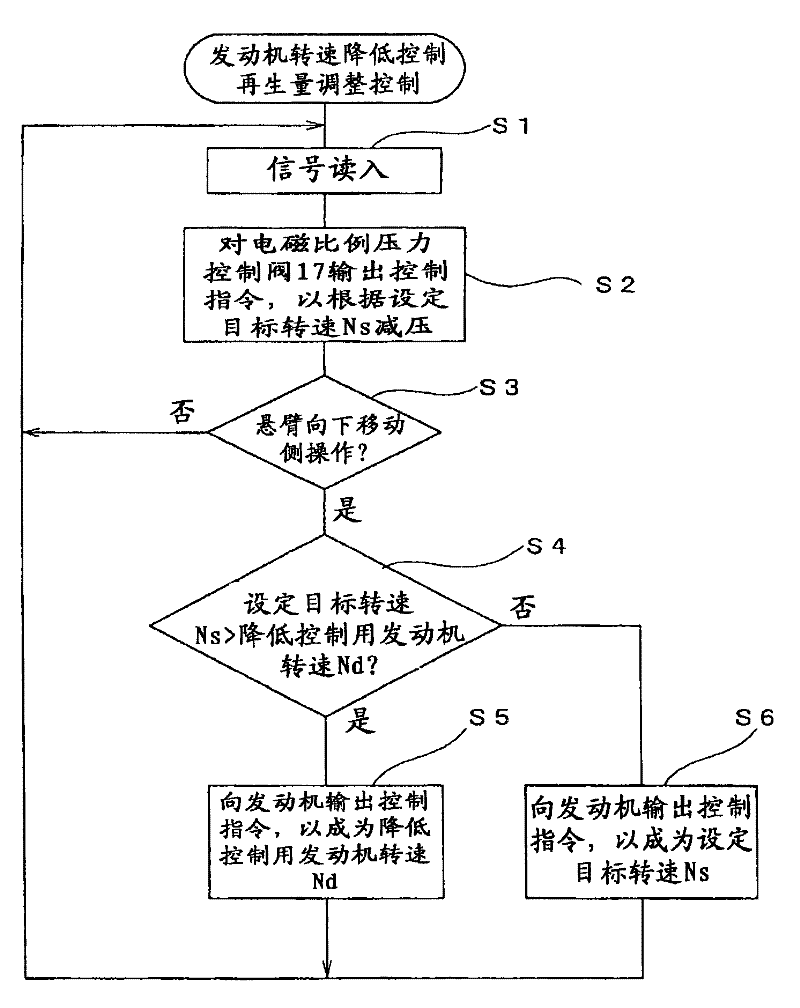

[0033] Next, according to Figure 1 ~ Figure 3 The first embodiment of the present invention will be described. in figure 1 Among them, 1 is a hydraulic excavator. The hydraulic excavator 1 includes: a crawler-type lower running body 2; an upper rotating body 3 rotatably supported on the lower running body 2; and an upper rotating body 3 mounted on it The front working machine 4, etc., and the front working machine 4 includes: a cantilever 5 supported on the upper rotating body 3 movably at its base end; an operating lever 6 supported at the front end of the cantilever 5 freely swinging back and forth; The bucket 7 and other parts attached to the front end of the operating lever 6 are provided with left and right traveling motors, rotating motors, boom cylinders 8, operating lever cylinders 9, and bucket cylinders 10 (not shown). The basic structure of the hydraulic actuator is the same as before. In addition, in figure 1 Among them, 1a is the space of the operator's cab.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com