Receptacle optical module and method for manufacturing the same

A manufacturing method and technology of optical modules, applied in optics, light guides, lasers, etc., can solve the problem that the laser beam profile is not a perfect circle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

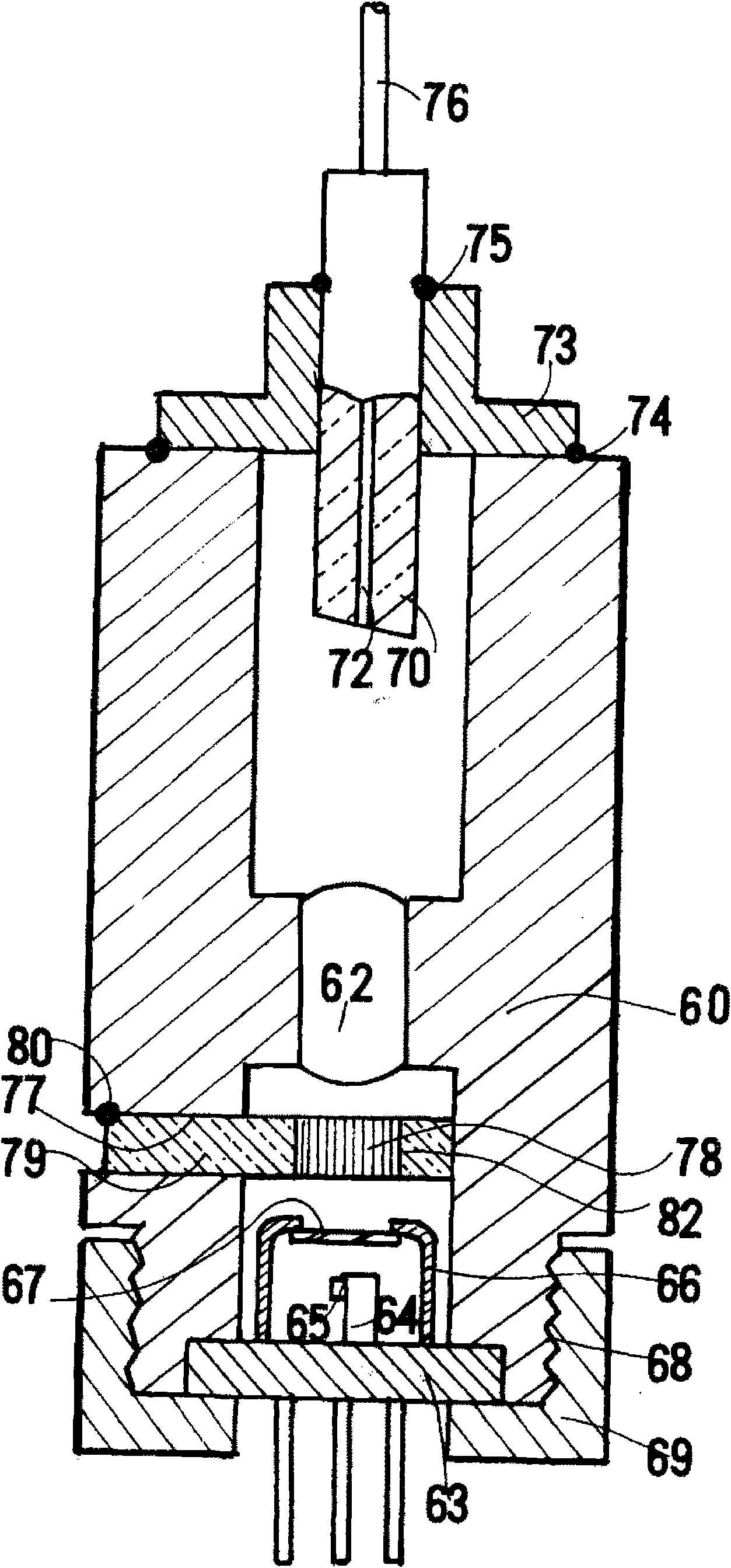

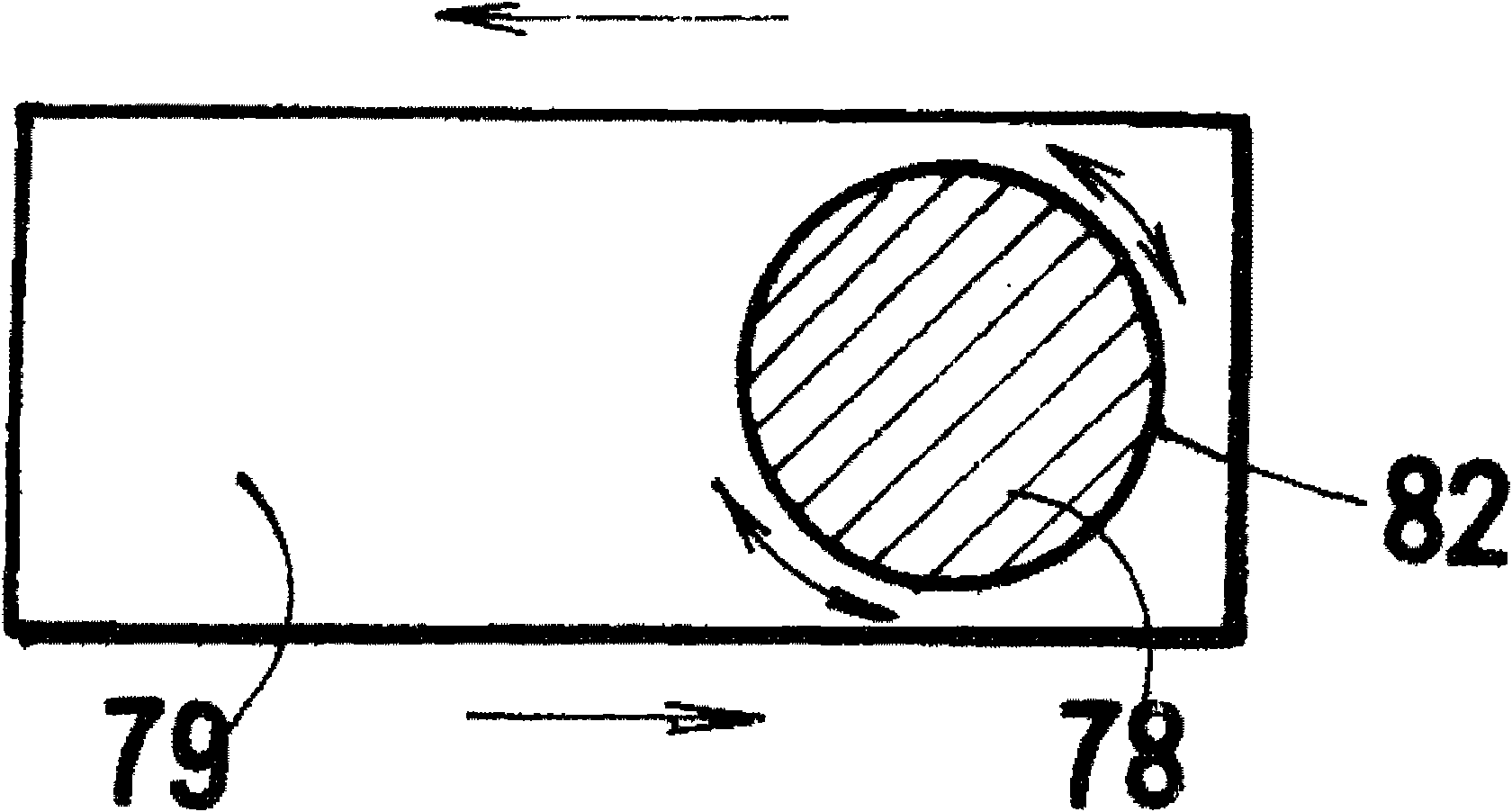

Embodiment 1

[0100] In the present invention, between the light-emitting light-concentrating part including the light-emitting element chip (LD) and the lens, and the socket part including the fiber stub (Fiber stub) and detachably holding the external optical fiber, a rotationally symmetrical shape is provided and maintained. Optical elements with polarization properties on the joint sleeve. First, adjust the positional relationship between the light-emitting concentrating system and the optical fiber ferrule to the quasi-optimum position (the point with the largest amount of light in the XY and R directions, and point G on the extension line of the concentrating point H in the Z direction). The rotation angle of the optical element with polarization characteristics that enables the external optical fiber to obtain a desired amount of light is obtained by rotating the splice sleeve and the optical element with polarization characteristics integrally. And, at this angle, the joint sleeve, ...

Embodiment 2

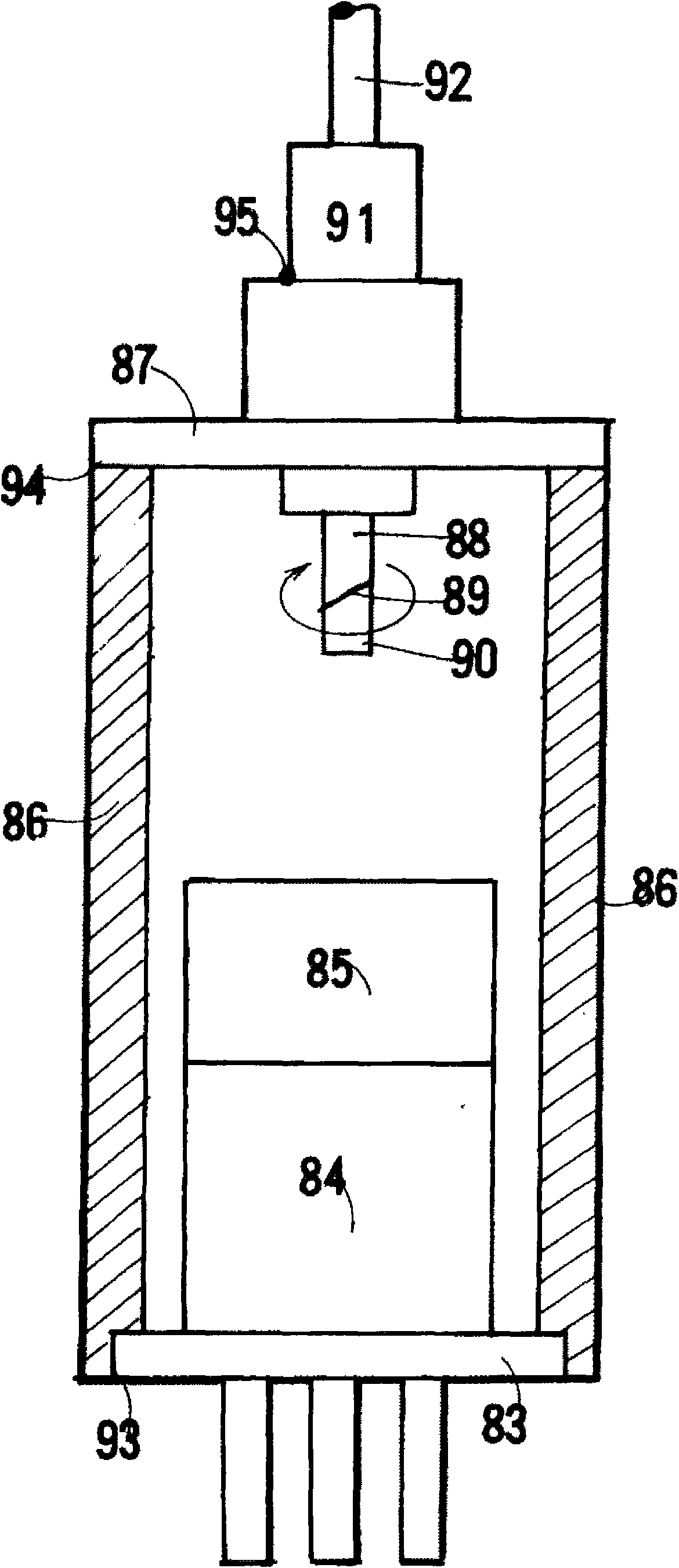

[0138] In the present invention, a splice sleeve held in a rotationally symmetrical shape is provided between the light-emitting converging section including the light-emitting element chip (LD) and the lens, and the socket section including the fiber ferrule and detachably holding the external optical fiber. Optical elements with polarization properties. Adjust the positional relationship between the light-emitting concentrating system and the optical fiber ferrule to the quasi-optimum position (the point with the largest amount of light in the XY and R directions, and the G point on the extension line of the concentrating point H in the Z direction). The rotation angle of the optical element with polarization characteristics that enables the external optical fiber to obtain a desired amount of light is obtained by rotating the splice sleeve and the optical element with polarization characteristics integrally. Under this angle, the joint sleeve, the light-emitting concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap