Bag cultured edible fungus liquid spawn full automatic inoculation machine and operation process thereof

A technology of liquid strains and edible fungi, applied in horticulture, application, botanical equipment and methods, etc., can solve the problems of low automation of the inoculation machine, coordination and comprehensive control of automatic transfer of bacteria bags, easy contamination of strains, etc. , to achieve the effect of reducing the requirements of the aseptic working environment of the machine, the value of popularization and application, and the high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

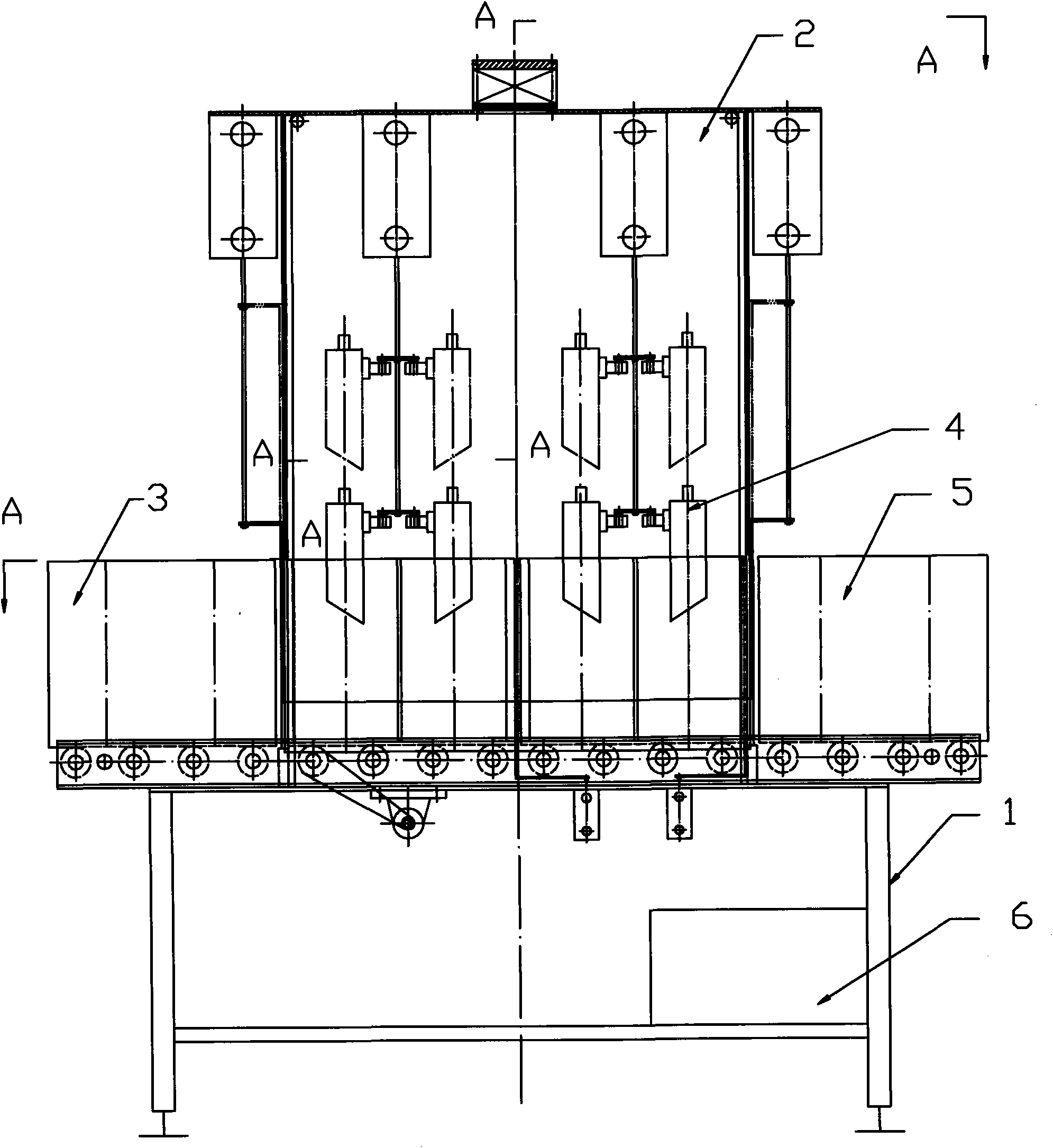

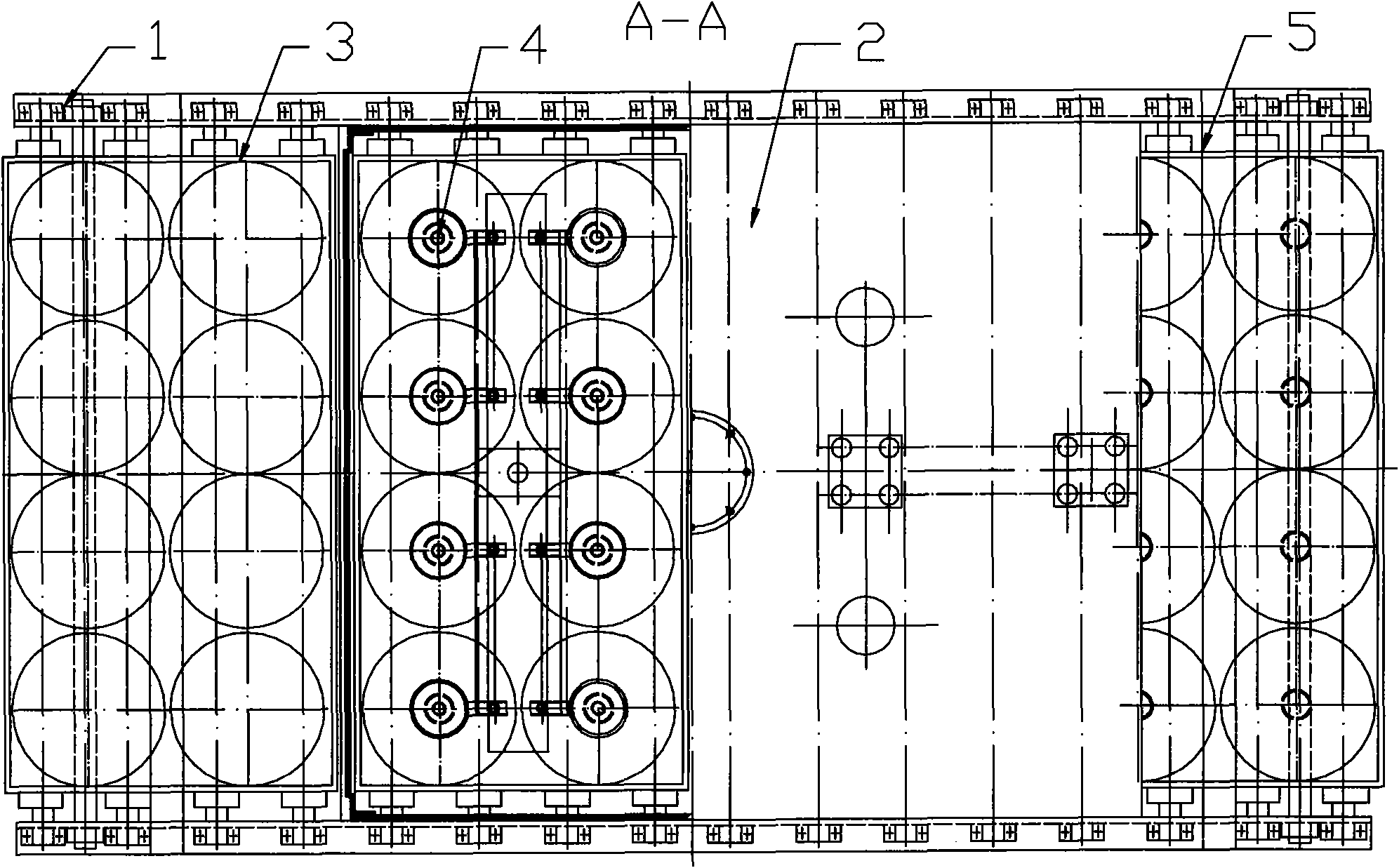

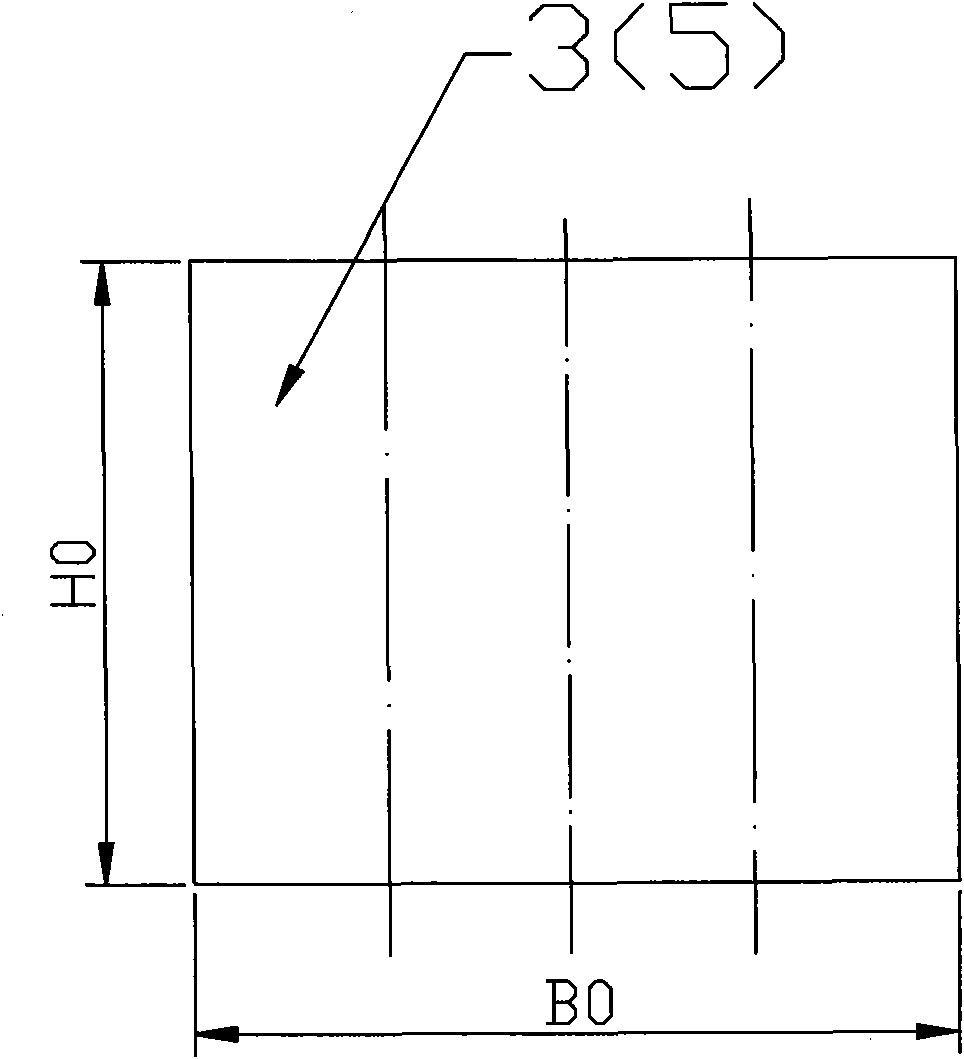

[0024] like figure 1 , 2 As shown, the invented fully automatic inoculating machine for bag-grown edible fungus liquid has a roller conveyor 1, an inoculation purification working chamber 2, a cultivation bag frame to be inoculated 3, a double-station multi-point automatic inoculation sealing part 4, an inoculated cultivation bag Frame 5 and automatic controller 6 and other components. The installation position relationship of the whole machine is: the inoculation purification working chamber 2 is installed in the middle part of the stick conveyor 1. Along the conveying direction, the left side is the input buffer area of the frame 3 of the cultivation bag to be inoculated, and the right side is the output buffer area of the frame 5 of the inoculated cultivation bag. , install the double-station 8-point automatic inoculation sealing part 4 inside the inoculation purification working chamber 2, and install the automatic controller 6 under the stick conveyor.

[0025] like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com