Direct current controlled underwater test tree

A technology for controlling water and testing trees, applied in wellbore/well components, earthmoving, sealing/packing, etc., can solve problems such as easy leakage of hydraulic oil, pollution of hydraulic system stability, slow response speed of hydraulic control, etc. , to avoid waste of time and capital costs, improve work efficiency and response speed, and solve the effect of control and response lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

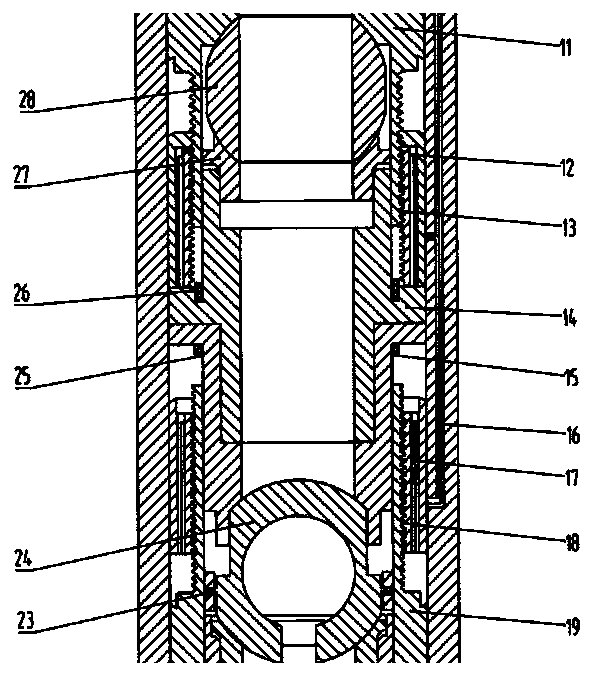

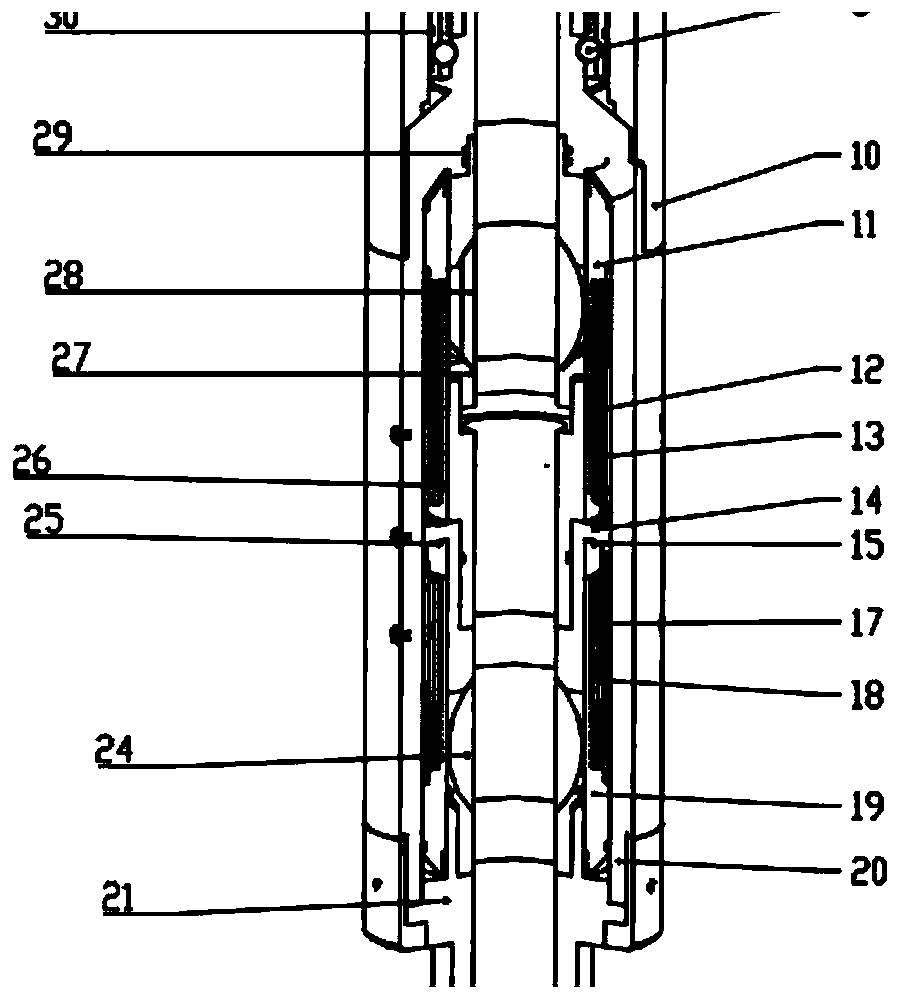

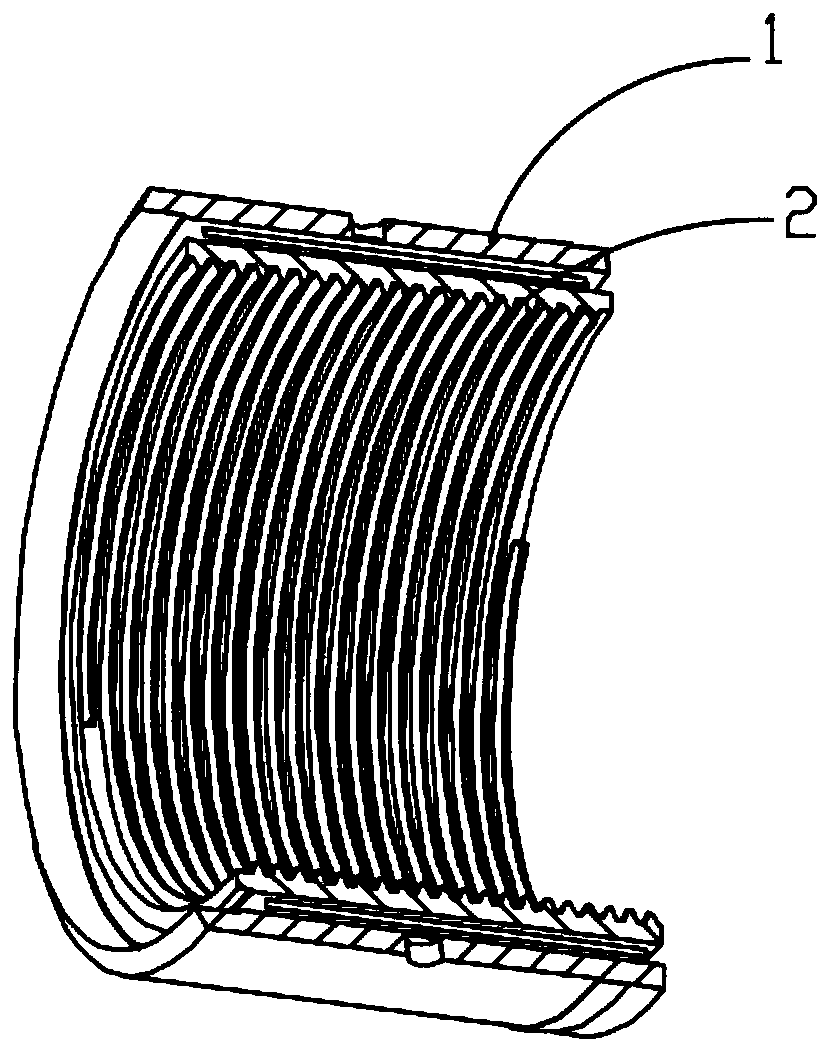

[0033] When the upper hollow shaft motor (1) receives the electric signal, the rotor (2) of the upper hollow shaft motor starts to rotate, and at the same time drives the upper movable push ring (3) to move, and the upper movable push ring (3) pushes to the right and drives the ball lock Mechanism (5) moves to the right, and the ball lock core (6) begins to move to the right under the effect of the driving force, when the ball lock core (6) moves to the middle pipe outer shell (10) (as Figure 4 ), because the diameter of the ball lock core installation hole (1001) of the middle pipeline outer shell (10) is smaller than the diameter of the ball, under the active force of the upper movable push ring (3), the ball lock core (6) is fixed on the middle pipeline outer shell (10) in the ball lock cylinder installation hole (1001), thus connecting the upper part and the middle part of the pipe, under the action of the ball lock mechanism (5), the connector pipe is connected with the s...

Embodiment approach 2

[0035] When an emergency occurs in the platform operation, first the middle hollow shaft motor (12) and the lower hollow shaft motor (17) rotate in reverse after receiving the signal, and the ball valve is closed through the cooperation of the rack and gear, and then the upper hollow shaft motor (1) is connected to the signal, the rotor (2) of the upper hollow shaft motor rotates in reverse, the upper movable push ring (3) moves upward to the limit position of the upper hollow shaft motor (1) under the constraint of the thread, and the upper hollow shaft motor (1) performs idling, At the same time, the sea level lifts the operating machine upwards, and the ball lock mechanism (5) moves upwards. Under the action of the ball lock mechanism (5), the ball lock core (6) is lifted from the ball lock core mounting hole (1001) of the middle pipe shell (10). ) slide out (such as Figure 5 ), and move upwards along with the upper acting machine, while the upper active push ring (3) limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com