Multifunctional welding and cutting device

A multi-functional, welding and cutting technology, applied in welding equipment, welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of troublesome operation, affecting work efficiency and quality, high labor intensity, etc., to achieve convenient operation, improve efficiency and Quality, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

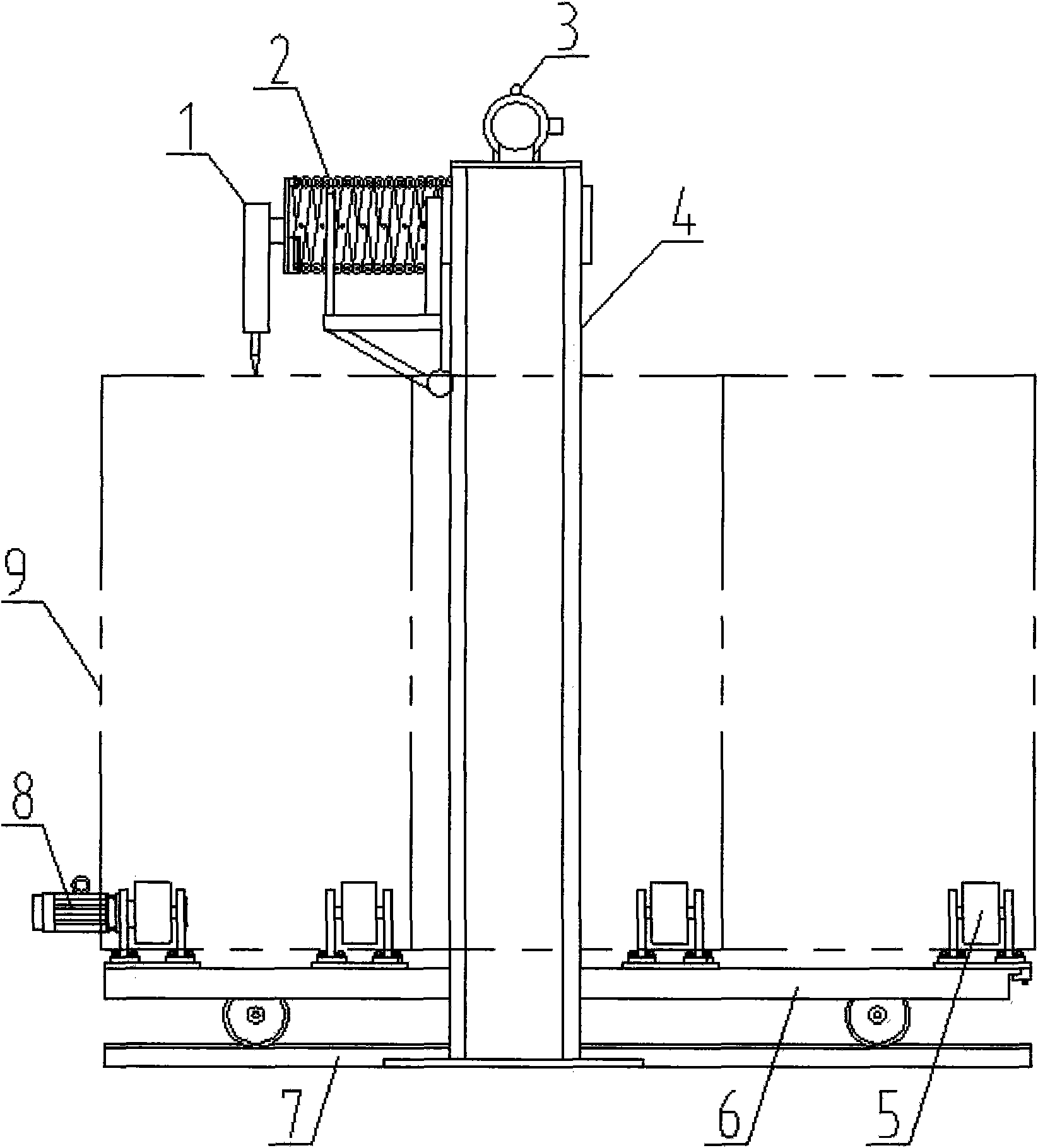

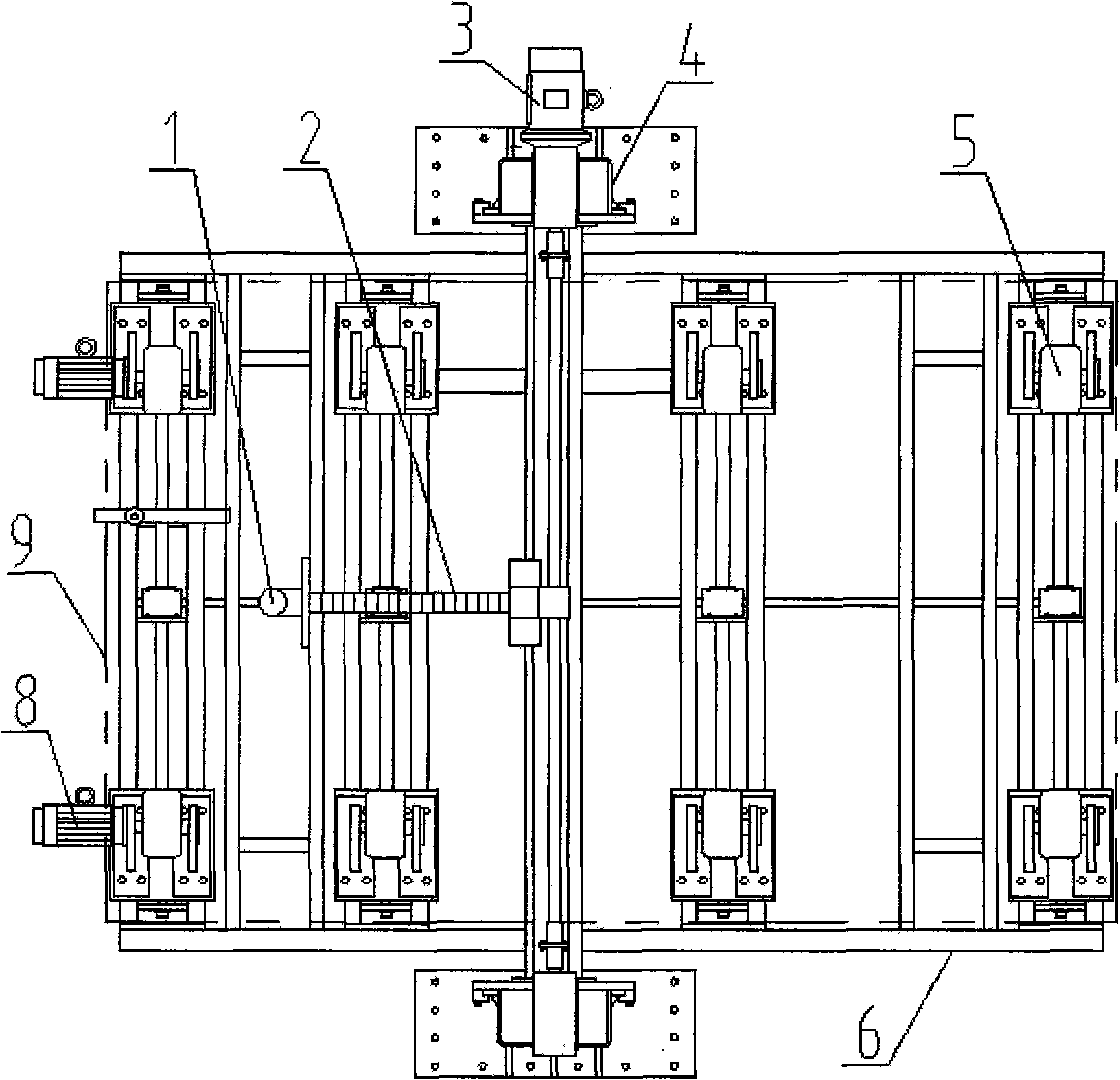

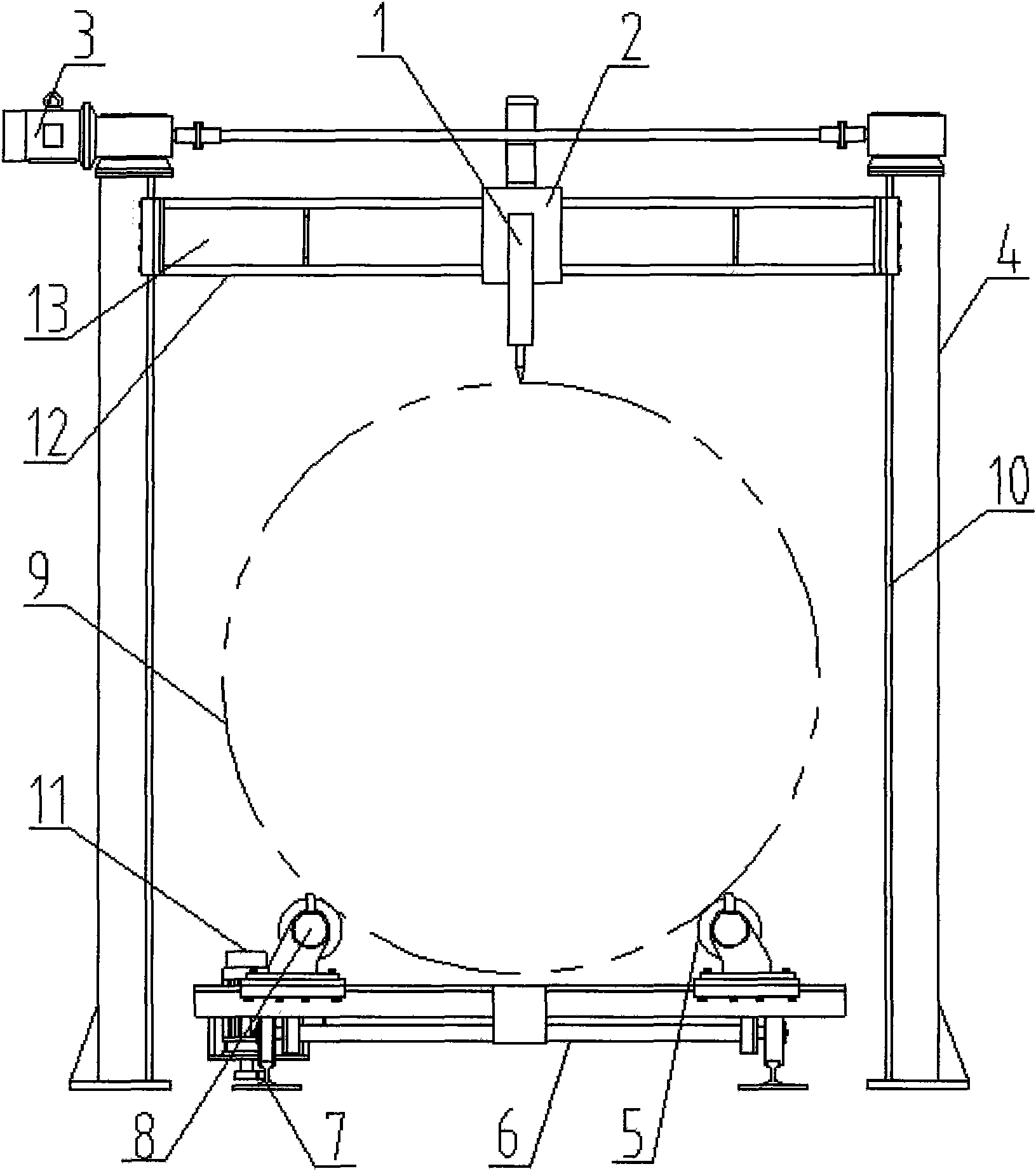

[0014] When the embodiment of the present invention is implemented, its designed main mechanism includes a welding torch 1, a telescopic support arm 2, a welding torch motor 3, a column 4, an idler 5, a workpiece supporting trolley 6, a rail 7, an idler motor 8, a longitudinal slideway 10, Dolly motor 11, beam 12 and transverse slideway 13. Wherein, the welding torch 1 is arranged on the beam 12 of the gantry type support through the telescopic support arm 2, the beam 12 is provided with the welding torch motor 3, the workpiece supporting trolley 6 is arranged under the welding torch 1, and the workpiece supporting trolley 6 is provided with the trolley motor 11 , the two sides of the workpiece support trolley 6 are symmetrically provided with four pairs of rollers 5, a pair of rollers 5 at the left end are connected with roller motors 8, and the wheels of the workpiece support trolley 6 are provided with rails 7 below.

[0015] The beam 12 of the gantry support is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com