Tractor with upward ball head and traction method thereof

A tractor and ball head technology, which is applied to traction connectors, transportation and packaging, vehicle parts, etc., can solve the problems of cumbersome assembly and complex structure, and achieve the effects of convenient assembly, feasible method and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

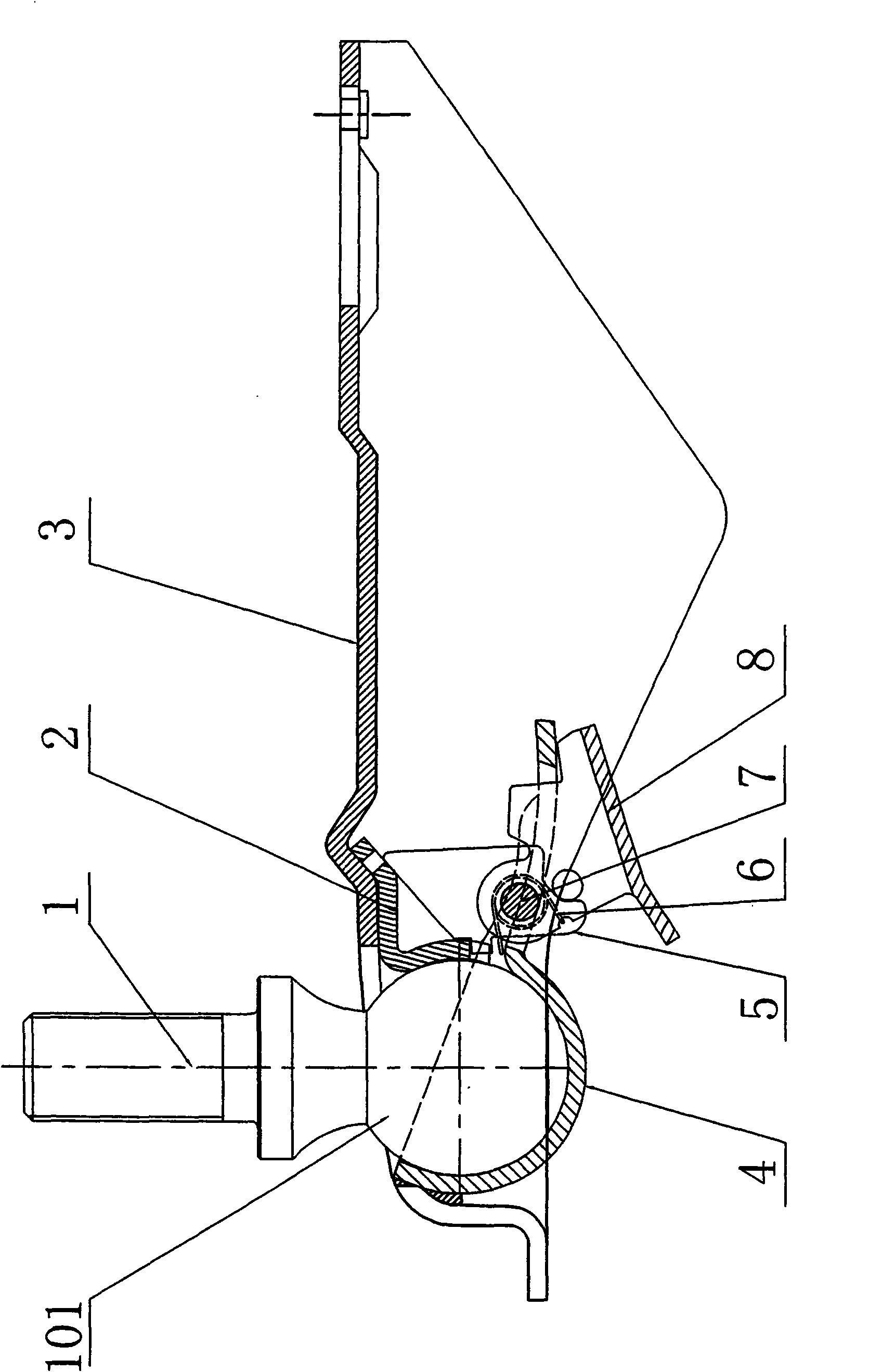

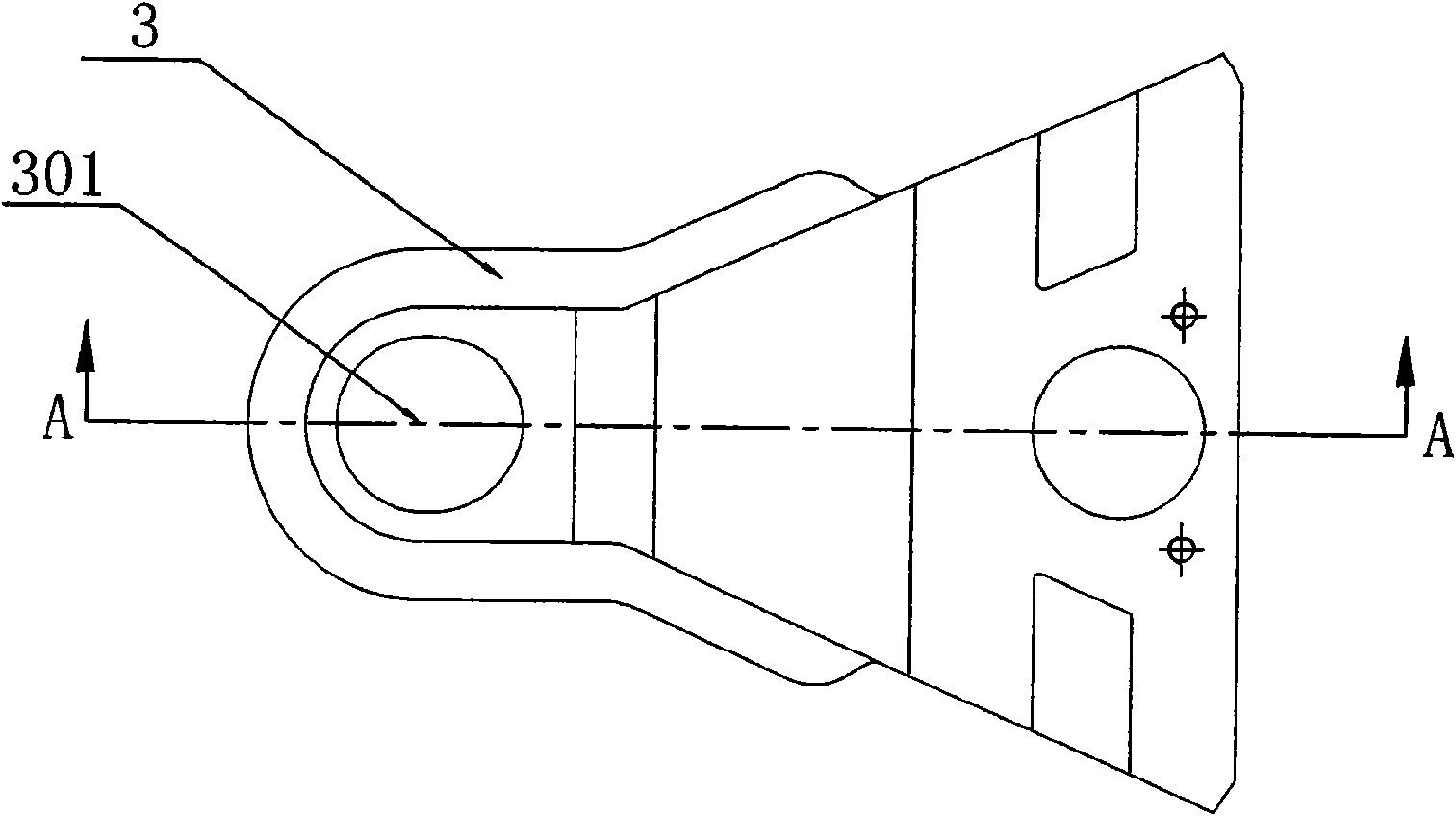

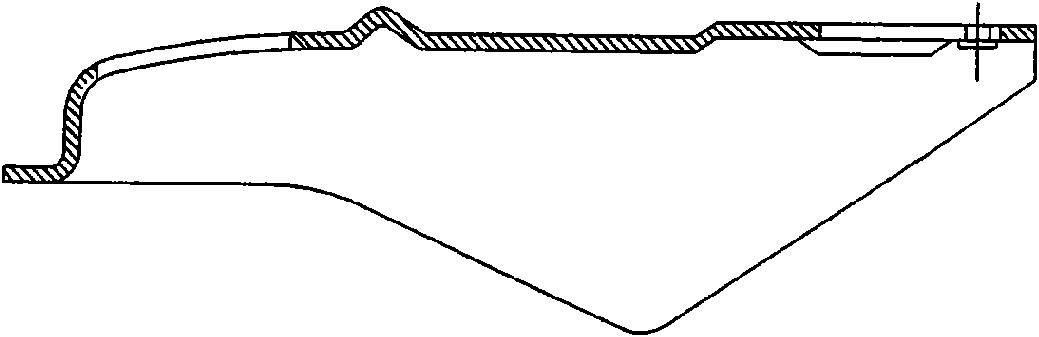

[0029] Now in conjunction with the above accompanying drawings, the structure of the present invention will be further described. The ball head upward tractor includes a traction head 1 , a housing 3 , an inner ball socket 4 , a support plate 5 , a torsion spring 6 and a wrench 8 . The wrench is provided with a symmetrical connecting plate 801, a symmetrical groove 803 and a symmetrical circular hole 802, wherein a group of large symmetrical circular holes is connected to the pin shaft 7, and the symmetrical groove is connected to the torsion spring handle 601. When pulling, because the ball head is facing upward, it is convenient to connect the threaded section of the pulling head with the connector of the puller. The ball 101 is placed in the housing hole 301 and offsets the arc 401 of the inner ball socket, so that the combination of the pulling force and the pulling force is achieved. When the power is in the best state, the towed car is pulled to the planned position. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com