Filled type combined self-heat conserving external wall and process

A self-insulation and filling technology, applied in the field of building materials, can solve the problems of lack of sound insulation and fire prevention, heat preservation, energy saving, light weight, large external wall structure, complex and cumbersome operation, etc., to improve construction flexibility, simple and fast installation, and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation plan

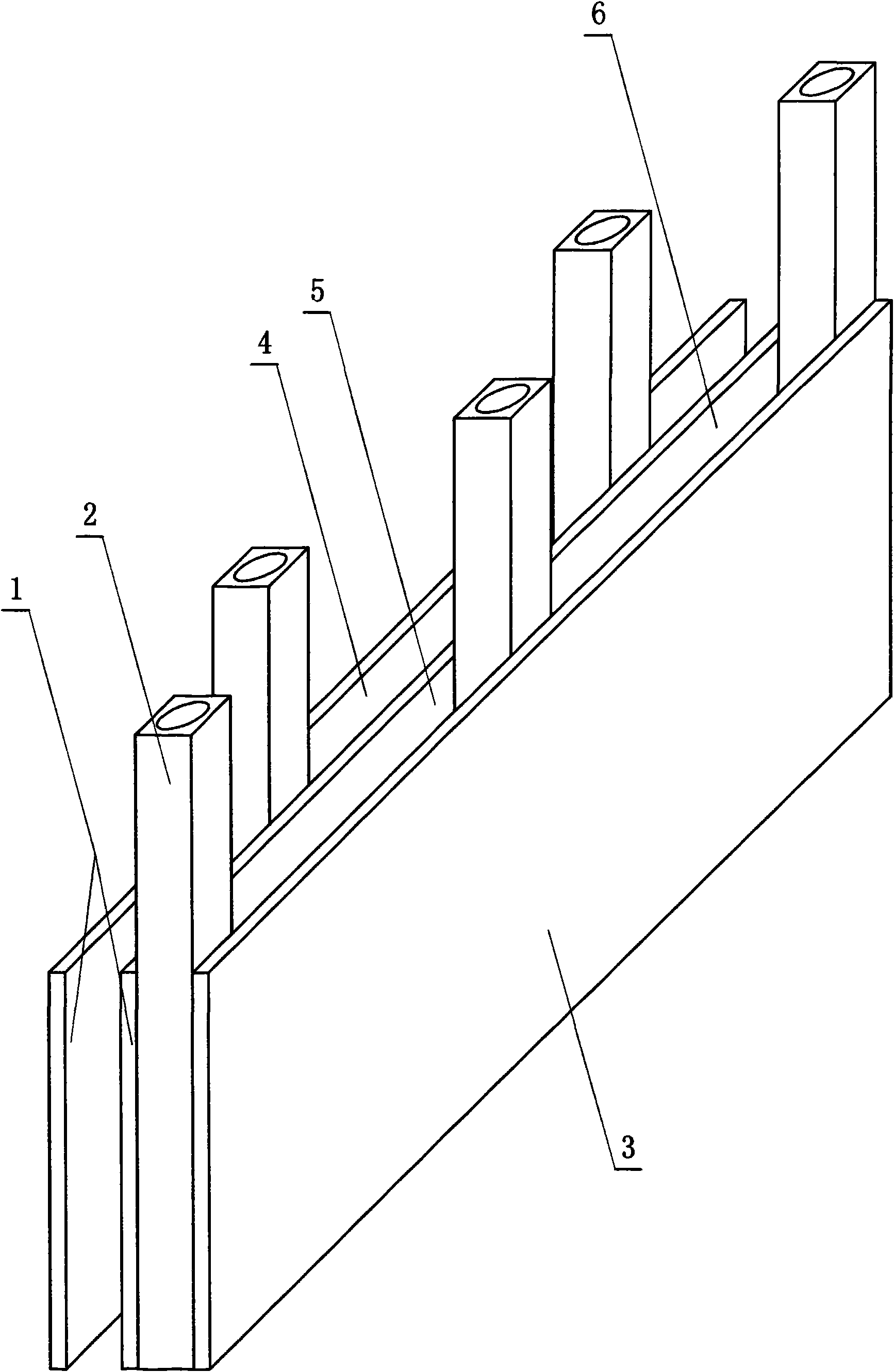

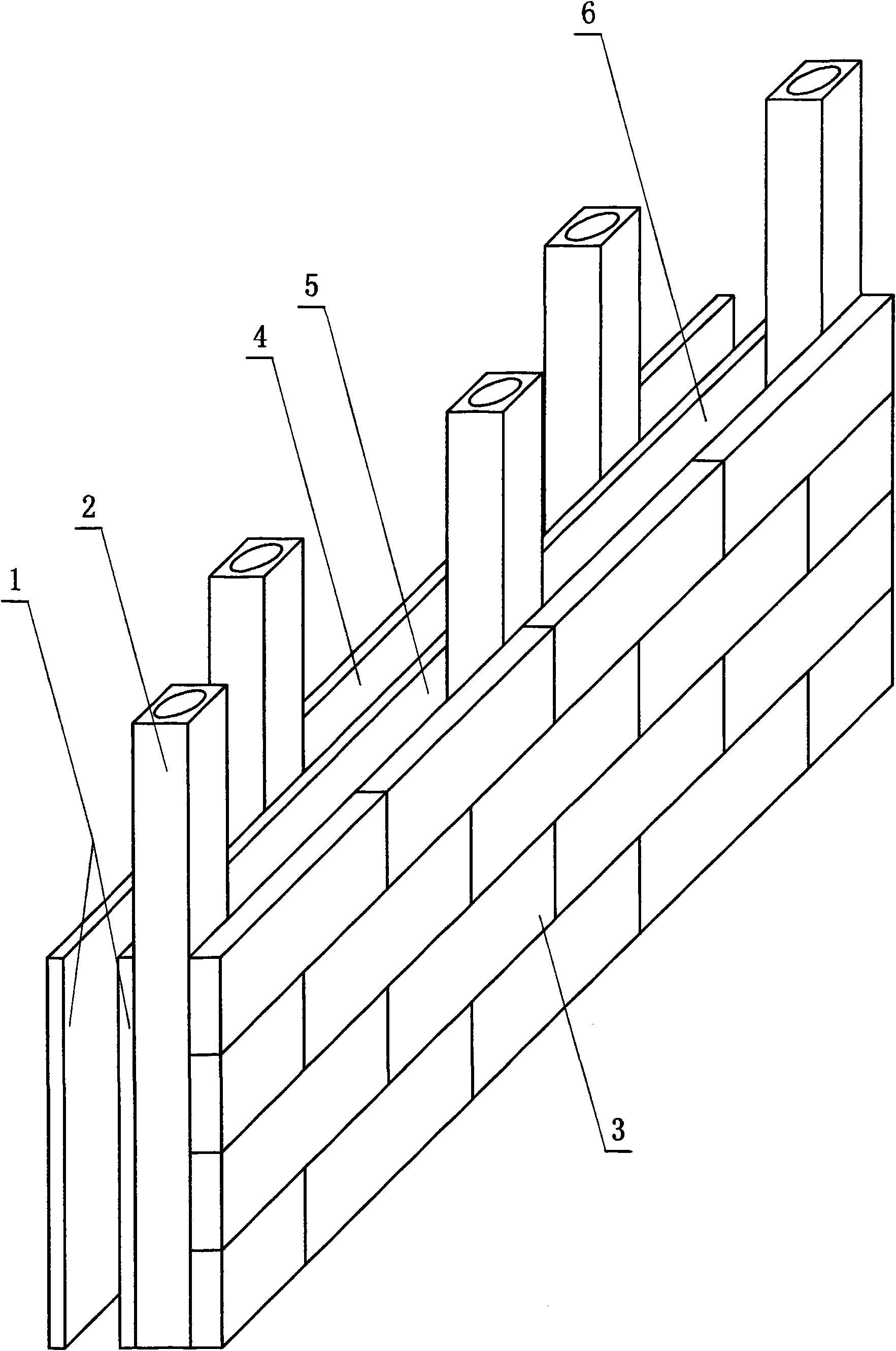

[0010] Such as Figure 1~2 The shown invention is mainly composed of gypsum slabs, keels and cement slabs (decorative bricks) to form a filled combined self-insulating exterior wall, which can adjust the functional requirements of the wall according to the different climates in the north and south, and fill the gaps with sound-insulating and heat-insulating cotton Or EPS, XPS, phenolic foam board or polyurethane foam slurry, cement foam slurry, very suitable for the exterior wall of the building.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com