Electrostatic antiscale all-glass evacuated photovoltaic collector tube

A photovoltaic power generation, all-glass technology, applied in the field of solar energy applications, can solve the problems of blocking scattered light from entering, serious scaling in the tube, poor thermal insulation performance, etc., and achieves the effects of reducing heat radiation, low production cost, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

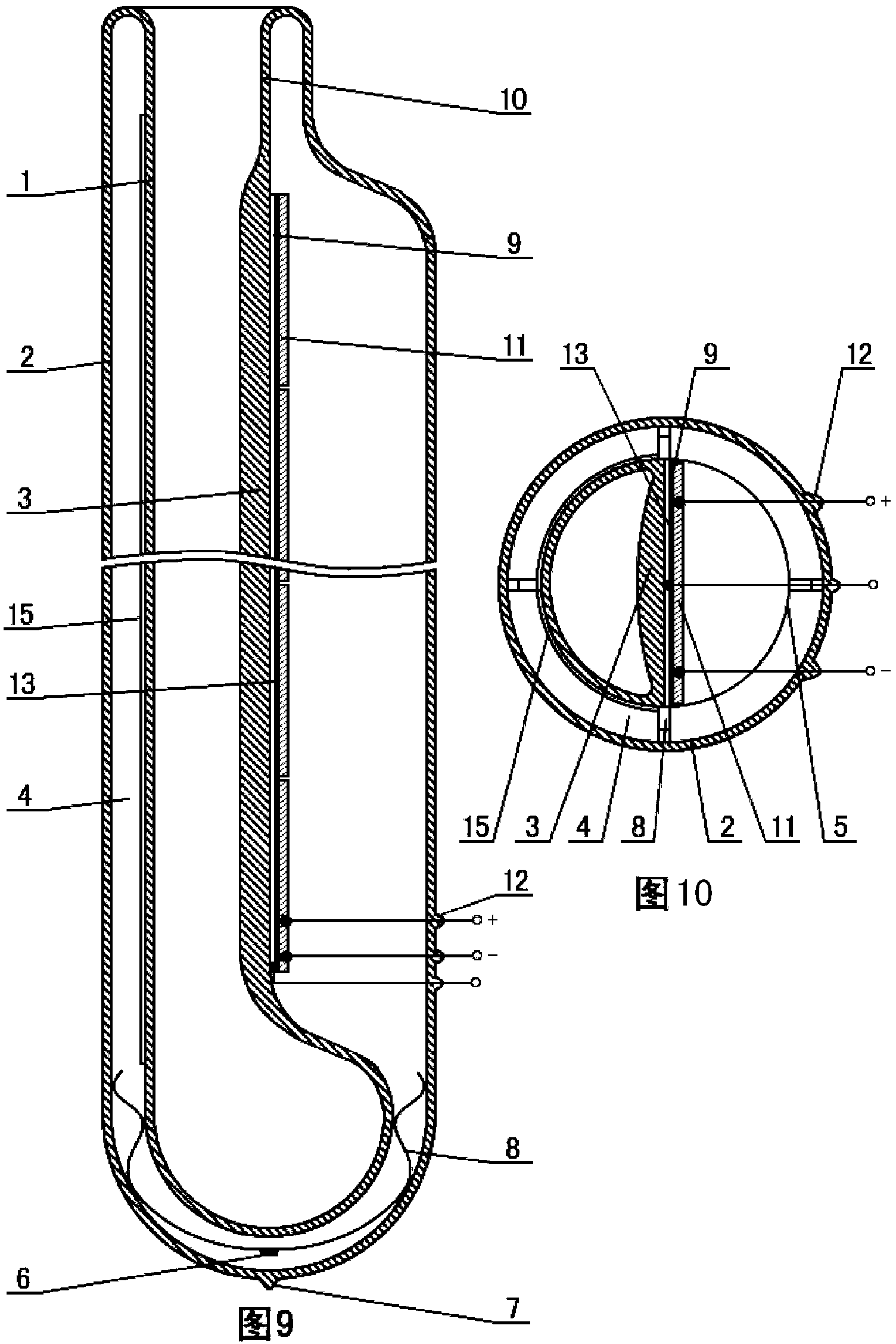

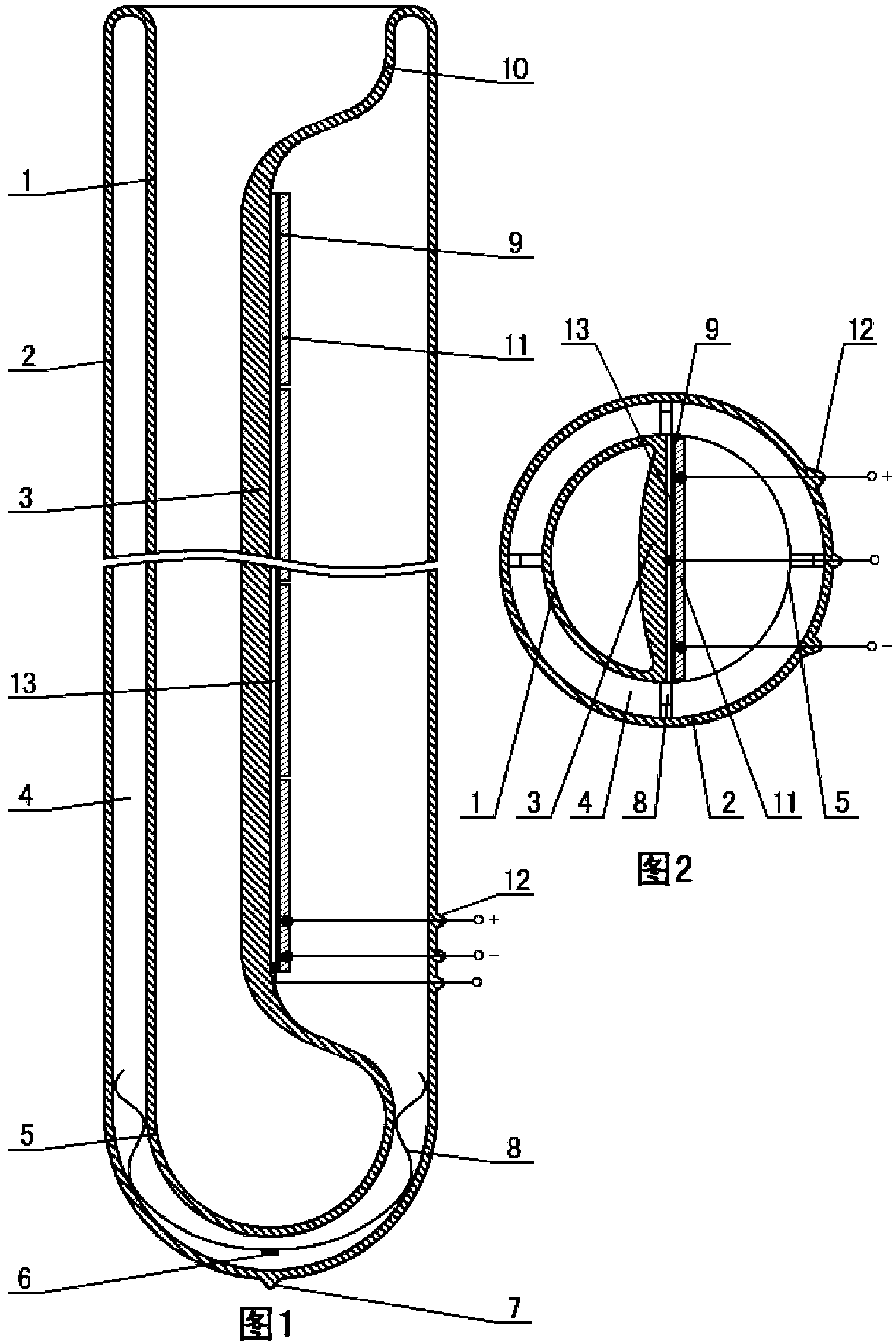

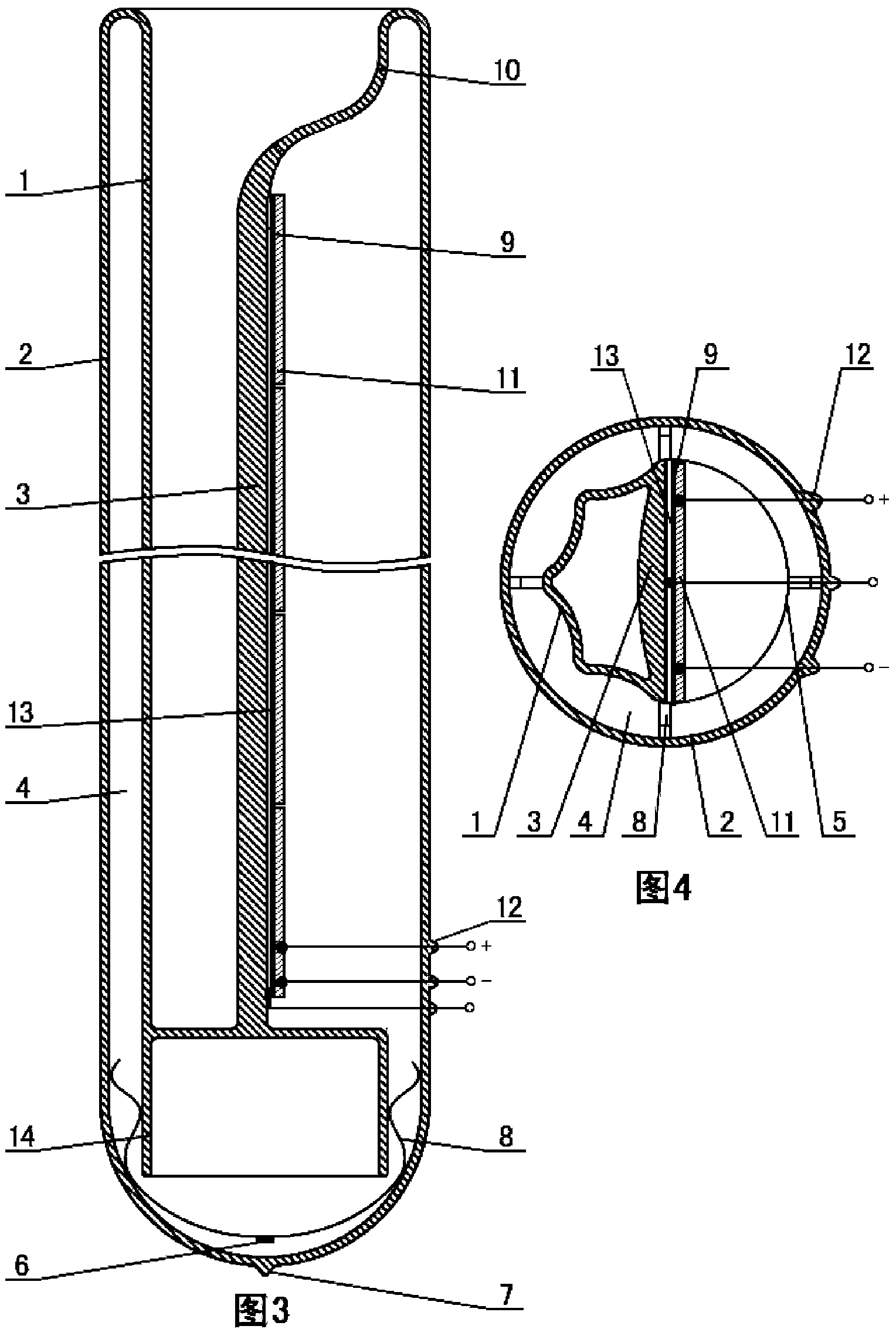

[0029] Such as figure 1 , 2 Shown: a semi-circular planar heat-collecting glass tube arc surface 1 of an electrostatic anti-fouling all-glass vacuum photovoltaic power generation heat collecting tube is a glass circular tube opening with the same diameter and the same diameter as the glass semi-circular tube 3 expanded. The other end of the glass semicircular tube 3 is first heated, molded, processed and expanded into a glass circular tube with the same center and equal diameter as the glass semicircular tube, and the glass is fused and sealed to form a glass circular tube 5, which is processed into an opening at one end, A glass semi-circular tube with one end closed is processed into a glass rectangular flat tube on the surface of its plane outer wall, first compounded with a conductive film layer 13, then compounded with an electrical insulating adhesive 9, and then compounded and connected to a photovoltaic cell composed of photovoltaic cells 11 connected in series. The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com