Knitted garment and production method thereof

A production method and clothing technology, applied in the direction of knitting, weft knitting, warp knitting, etc., can solve the problems of poor setting effect of clothes, wrinkling of clothes body, affecting dressing effect, etc. Sweat smell, luster soft and bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

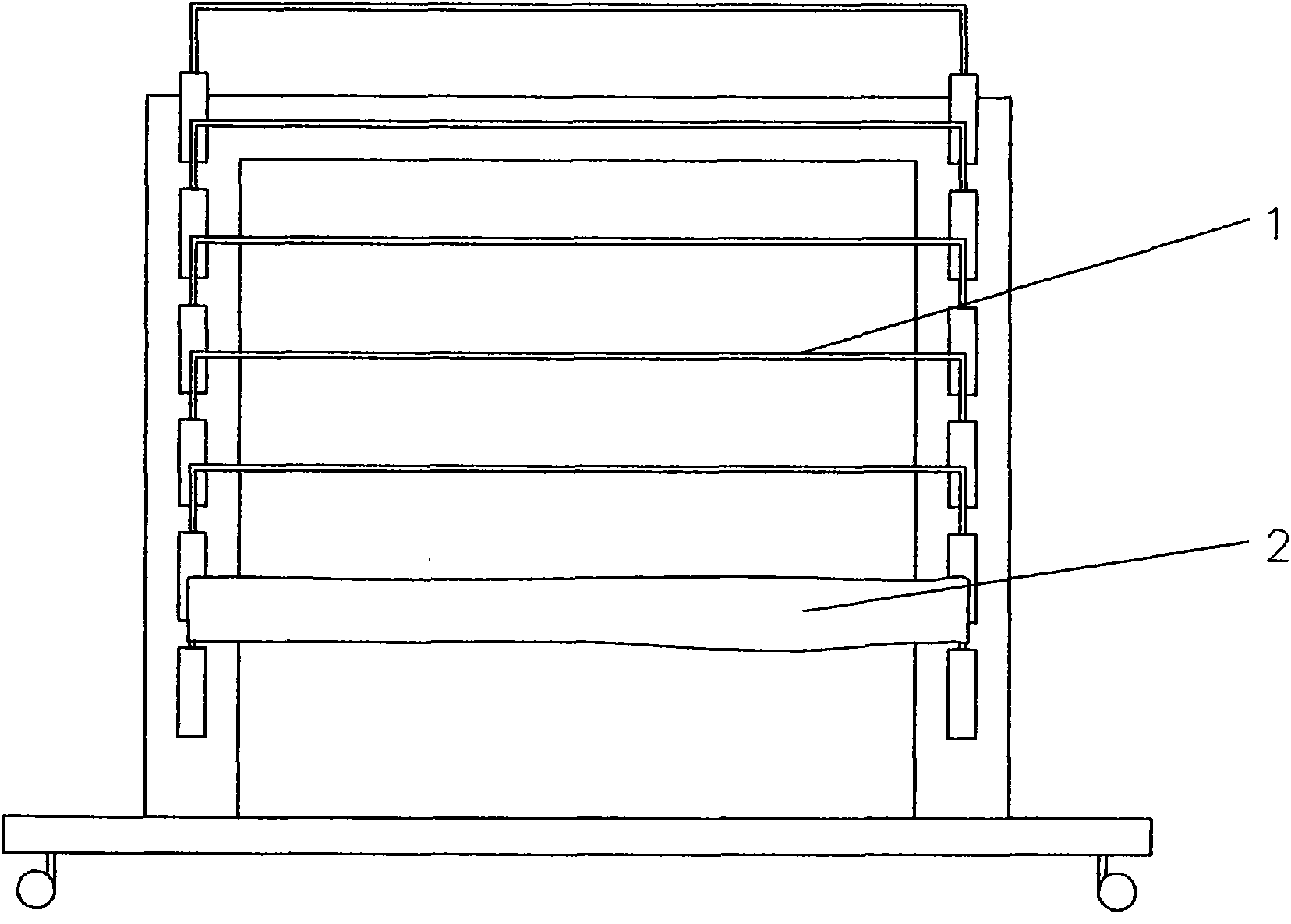

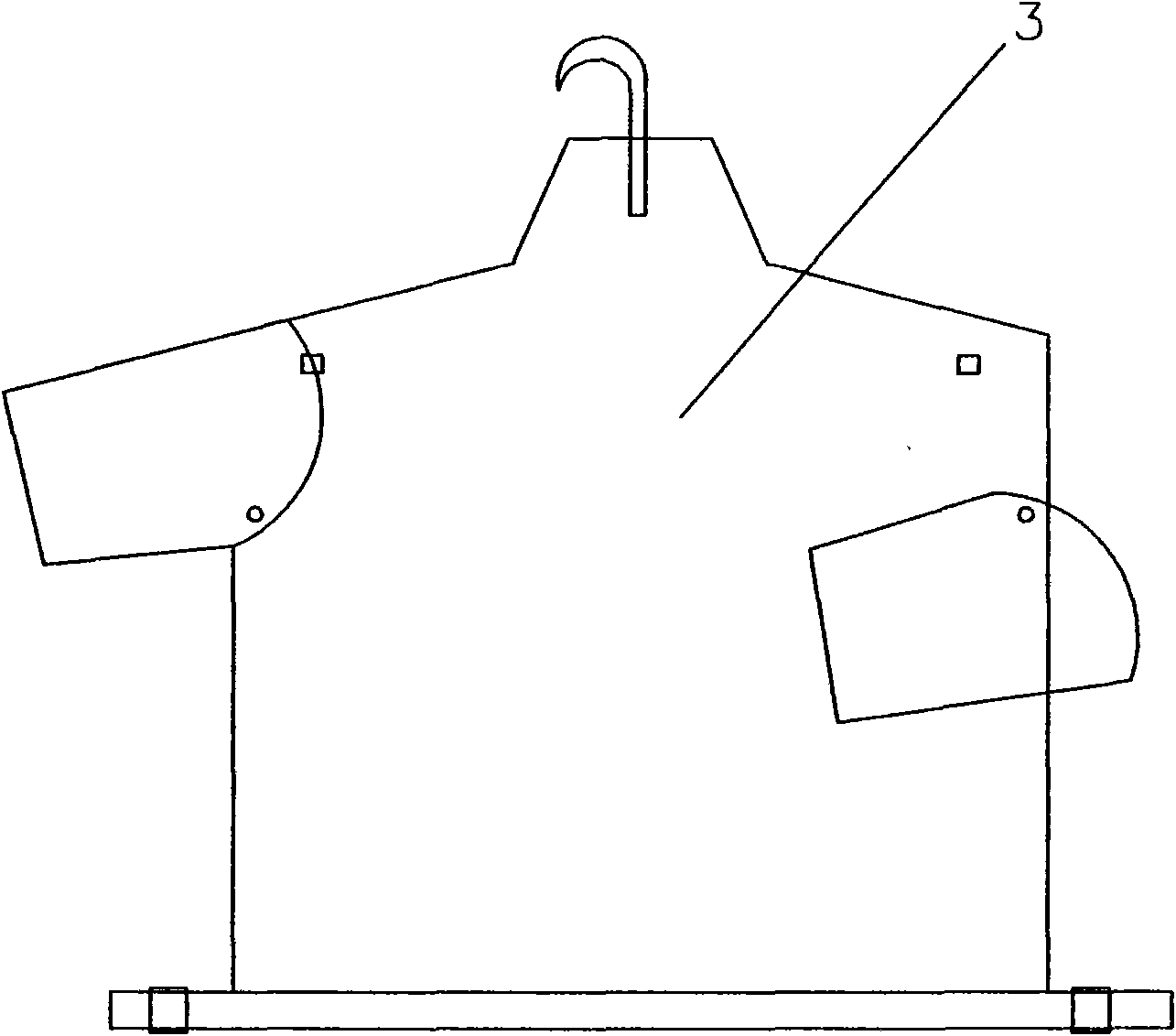

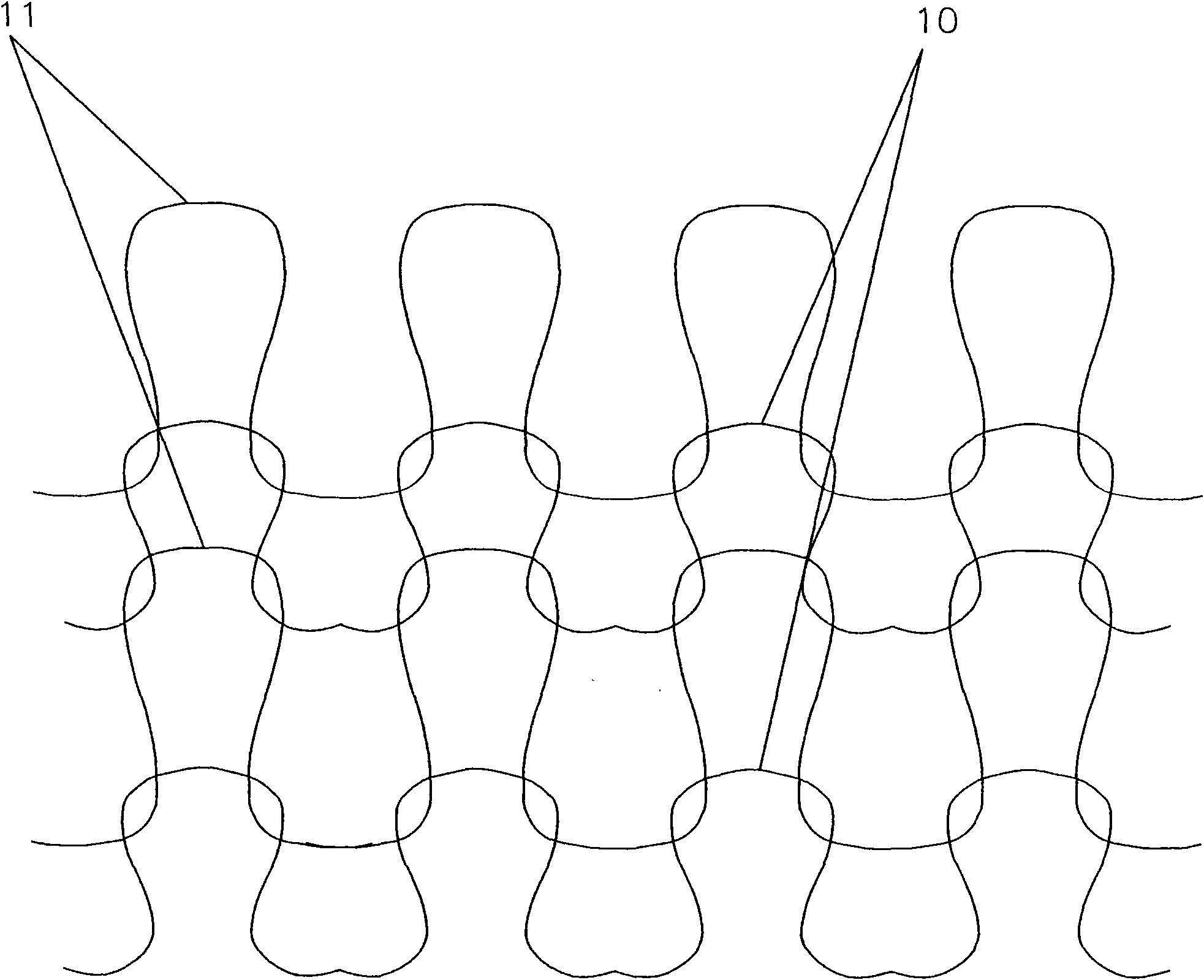

[0015] Such as figure 1 , figure 2 , image 3 As shown, a knitted garment described in this embodiment and its production method mainly include producing silk thread and then weaving the silk thread into a fabric, cutting the fabric into two parts of the collar 2 and the body that cooperate with each other, and putting them on respectively. Fully spread out on the collar rack 1 and the body rack 3, such as figure 1 , figure 2 As shown, put it into a pressure vessel and carry out 15-25 minutes steam pressure setting at 2.5kg of high-temperature steam setting, finally the body and collar are sewn together to make ready-made clothes. Simultaneously this knitwear is made of double-sided fabric, and double-sided fabric is to form the lining inner layer by mulberry silk as bottom line 10, and nylon silk forms the outer layer of fabric weaving as upper thread 11 and forms.

Embodiment 2

[0017] Such as Figure 4 As shown, a kind of knitted garment and its production method described in this embodiment, the nylon yarn is made of two strands of nylon yarn 5 respectively through the twisting device 4 for left-handed and right-handed twisting, and then processed through the network mouth 6 It is made by forming a network of silk threads and paralleling. The network nozzle 6 is a device that touches the left-handed and right-handed two strands of nylon filaments 5 together to form a network-like structure through an external force. This network nozzle 6 includes a wire-feeding channel 7, an air nozzle 8 is arranged on the side wall of the wire-running channel 7, and the air external force is provided by the air pump 9 to act on the nylon yarn, and this air external force can be spaced Sexuality occurs, so that the nylon filaments produce a uniform mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com