Machine room air-conditioning energy-saving operation control system

A technology of operation control and computer room air conditioning, which is applied in heating and ventilation control system, heating and ventilation safety system, space heating and ventilation, etc. It can solve problems such as uneven temperature setting, waste of electric energy use, and energy waste. Achieve obvious energy saving effect, precise monitoring and optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

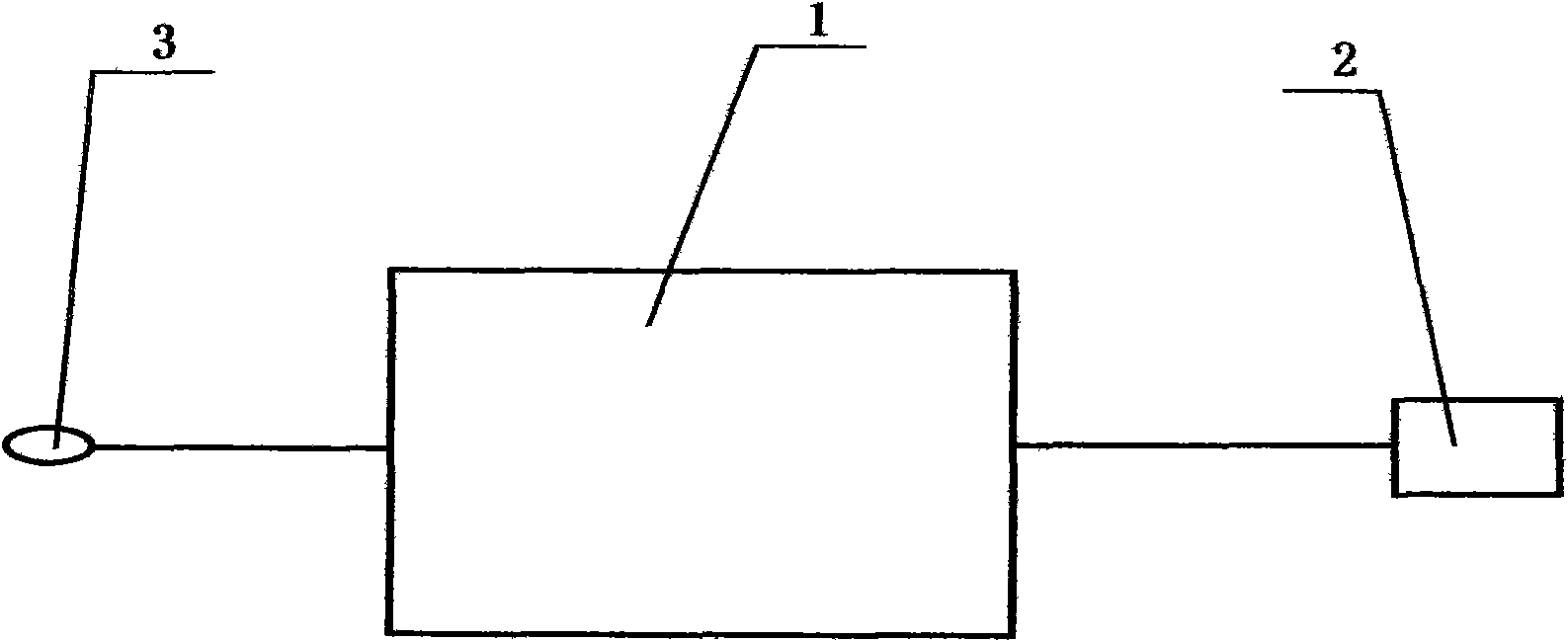

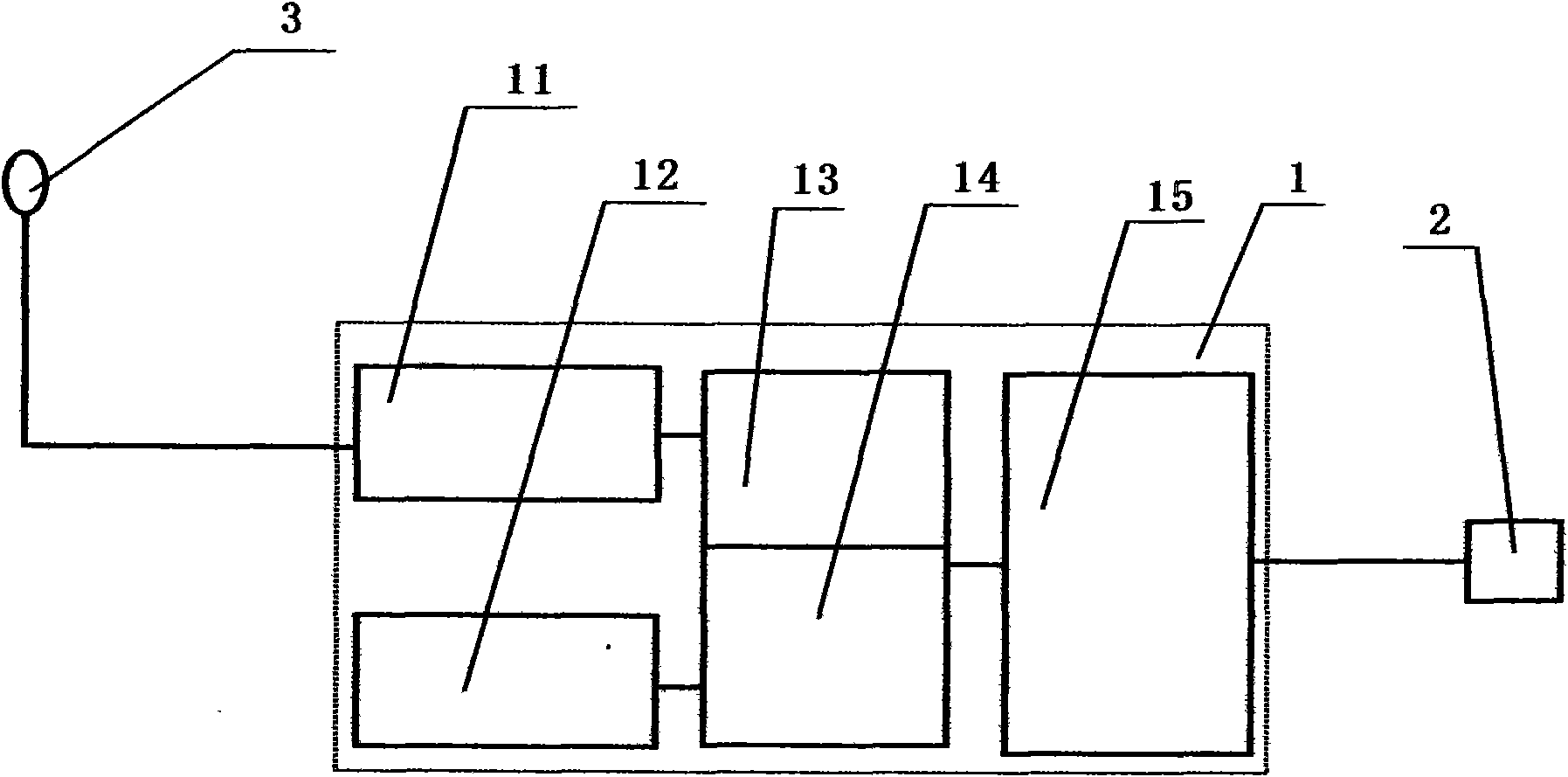

[0016] Figure 1 to Figure 2 The present invention shown in is mainly made up of control host (1), temperature compensation box (2) and temperature sensor (3), is characterized in that: temperature compensation box (2) and temperature sensor (3) are connected with control host ( 1) Connect to form a complete control system, wherein the control host (1) includes: a temperature setting module (11), a measurement module (12), a difference comparison module (13), a difference judgment module (14) and a compensation output The module (15), the temperature sensor (3) is set at the place where the cooling equipment is required, and is strictly oriented to the target object to achieve precise temperature control. The temperature compensation box (2) is made of refrigeration semiconductors, and it is connected with the air return port of the air conditioner (4). The return air temperature probe at (41) is connected, and the control host (1) passes through the temperature setting module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com