Adjustable multiple stress induced cracking device for concrete

An adjustable and concrete technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large crack randomness, no significant regularity, and poor sensitivity of the flat plate method, so as to achieve adjustability and shorten the test time. The effect of high time and test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

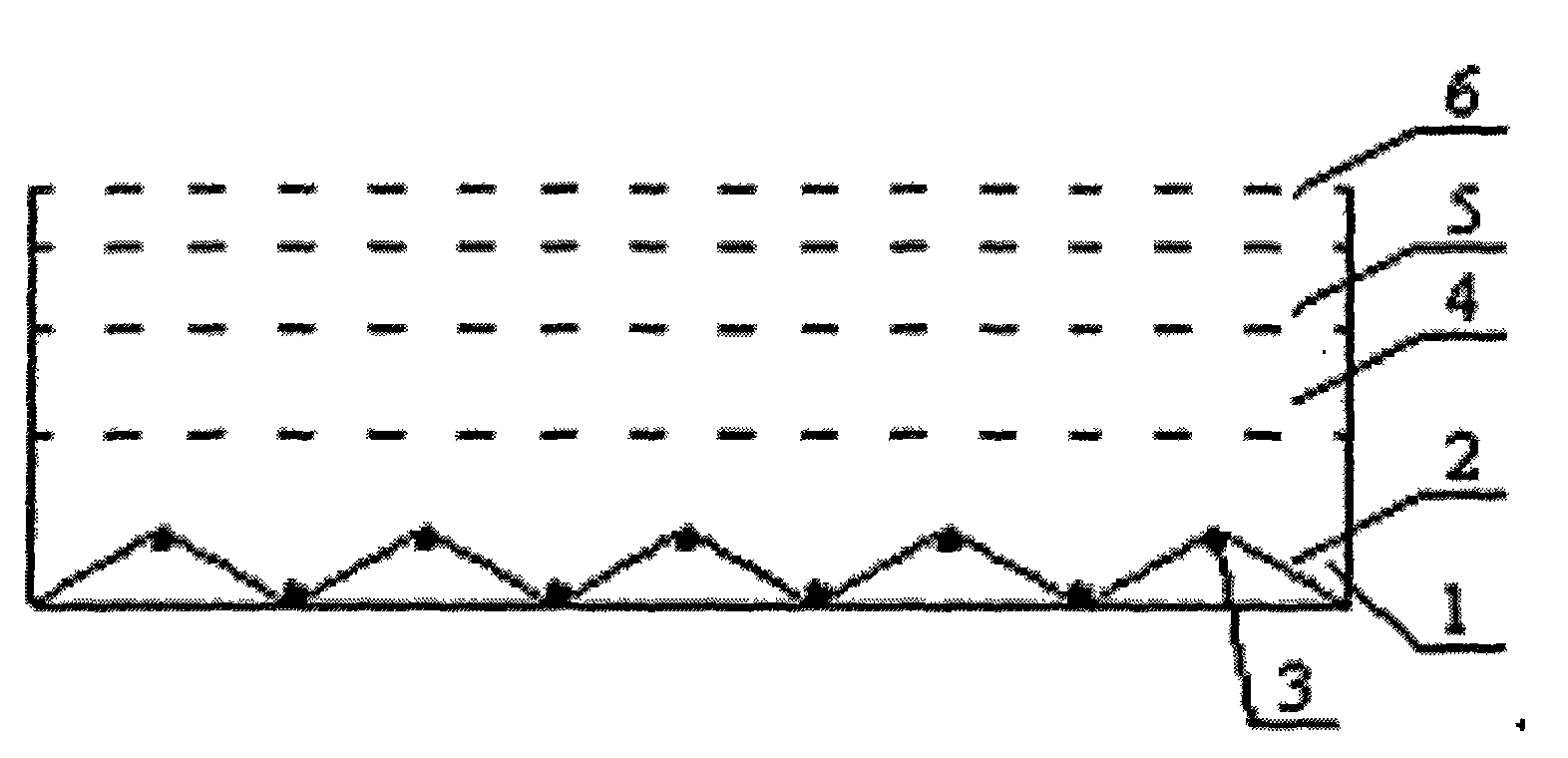

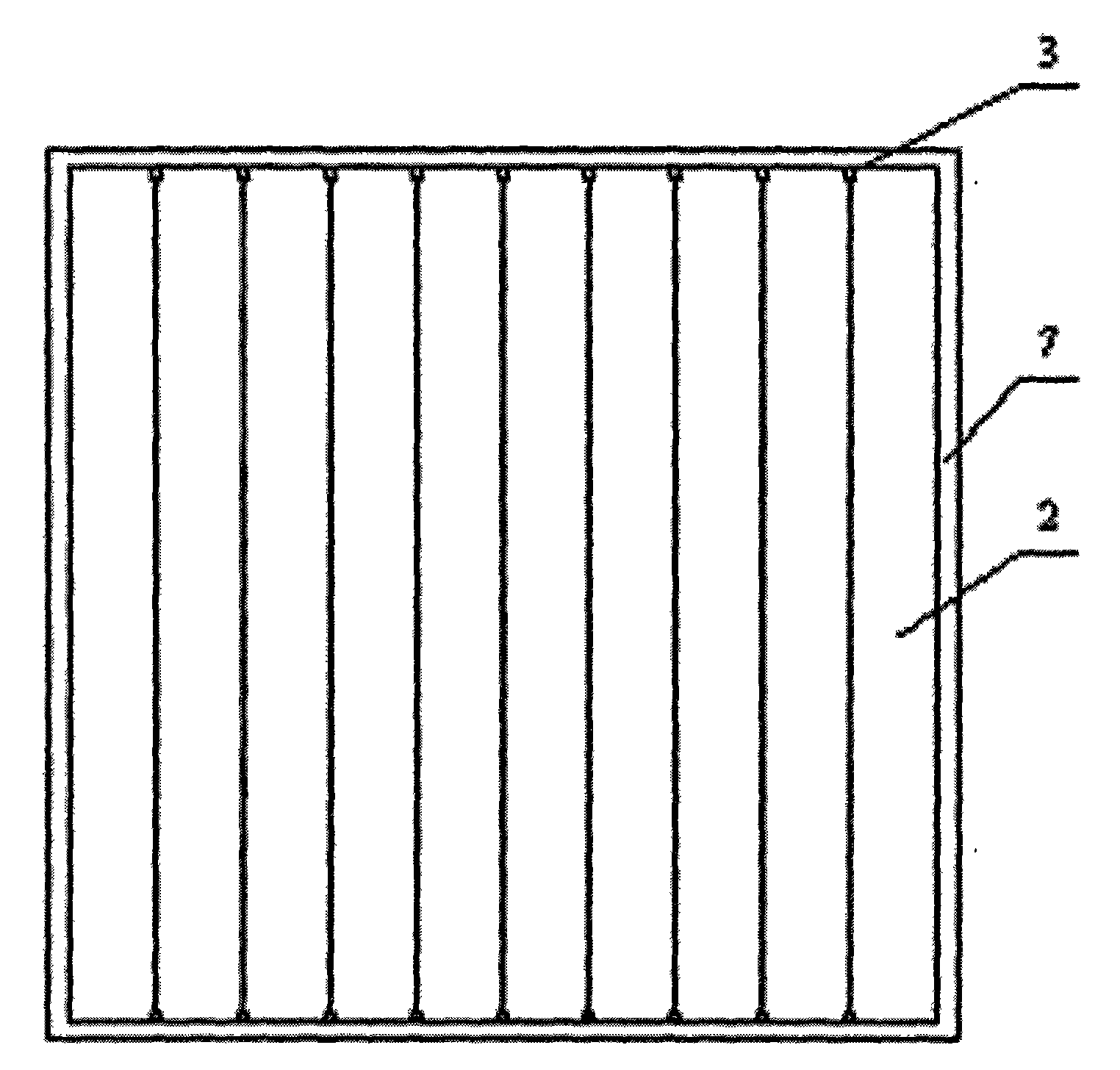

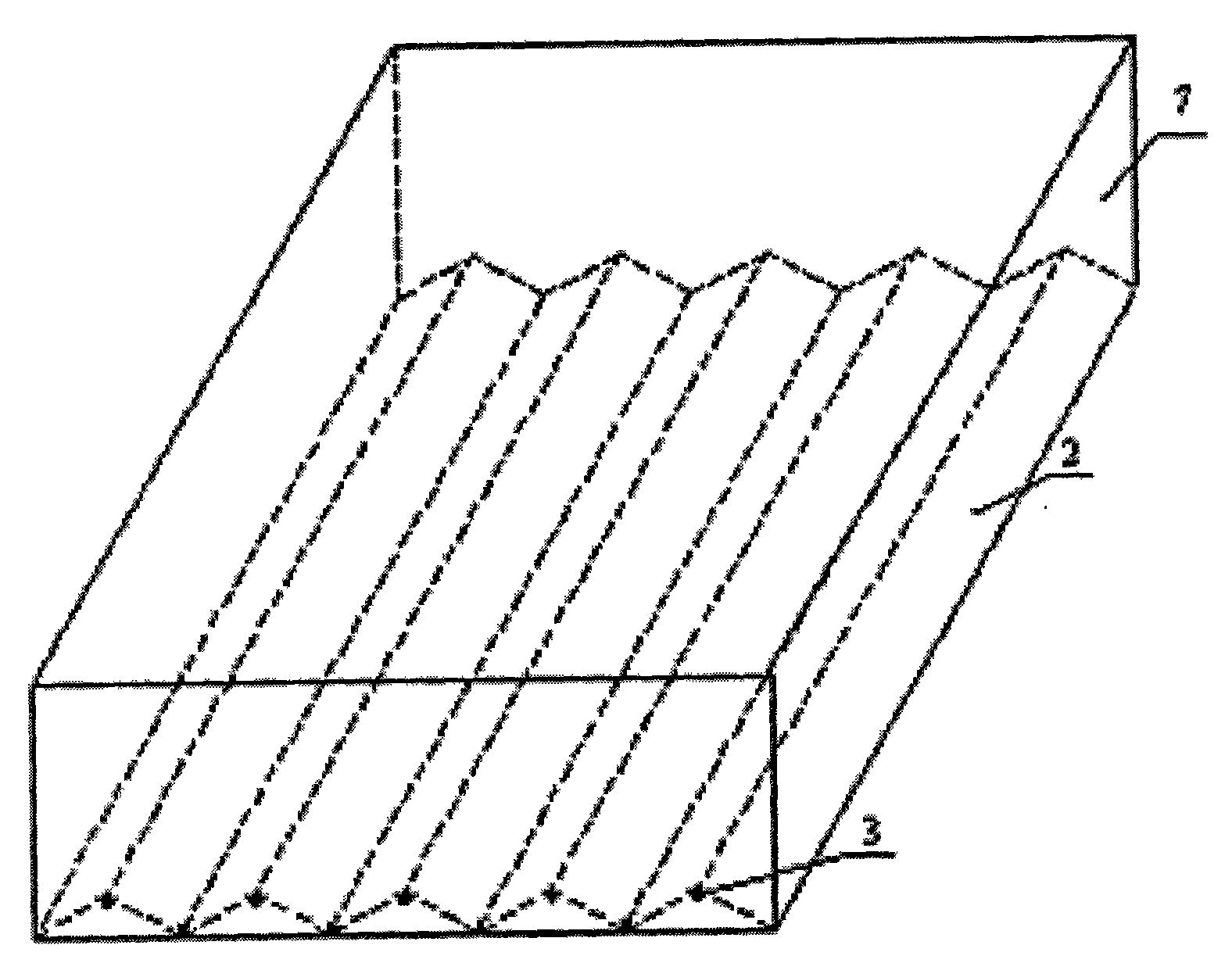

[0017] Embodiment 1, adjustable multi-stress concrete induced cracking device, with reference to figure 1 : The steel crack inducer 2 is placed on the steel frame 1 fixed on the steel frame 1 by the bottom steel frame 1 and the side plates 4, 5, 6, and the height and the top angle of the steel crack inducer 2 are adjusted by the adjusting nut 3 The angle realizes the adjustability of the angle and size of the induced crack initiation force. According to the maximum particle size of the coarse aggregate in concrete, the adjustment nut 3 selects the appropriate induced cracking force, and at the same time, the side plates 4, 5, and 6 are reasonably matched to adjust the height of the steel frame 1, which realizes the application of different aggregates. Concrete induced cracking device for diameter conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com