Color wheel and digital optical processing projector

A technology of color wheel and wheel sheet, which is applied in the field of digital light processing projectors, can solve the problems of color wheel sheet 145 falling off, deterioration of UV curing adhesive 144 bonding quality, etc., and achieve the effect of preventing bonding quality from deteriorating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

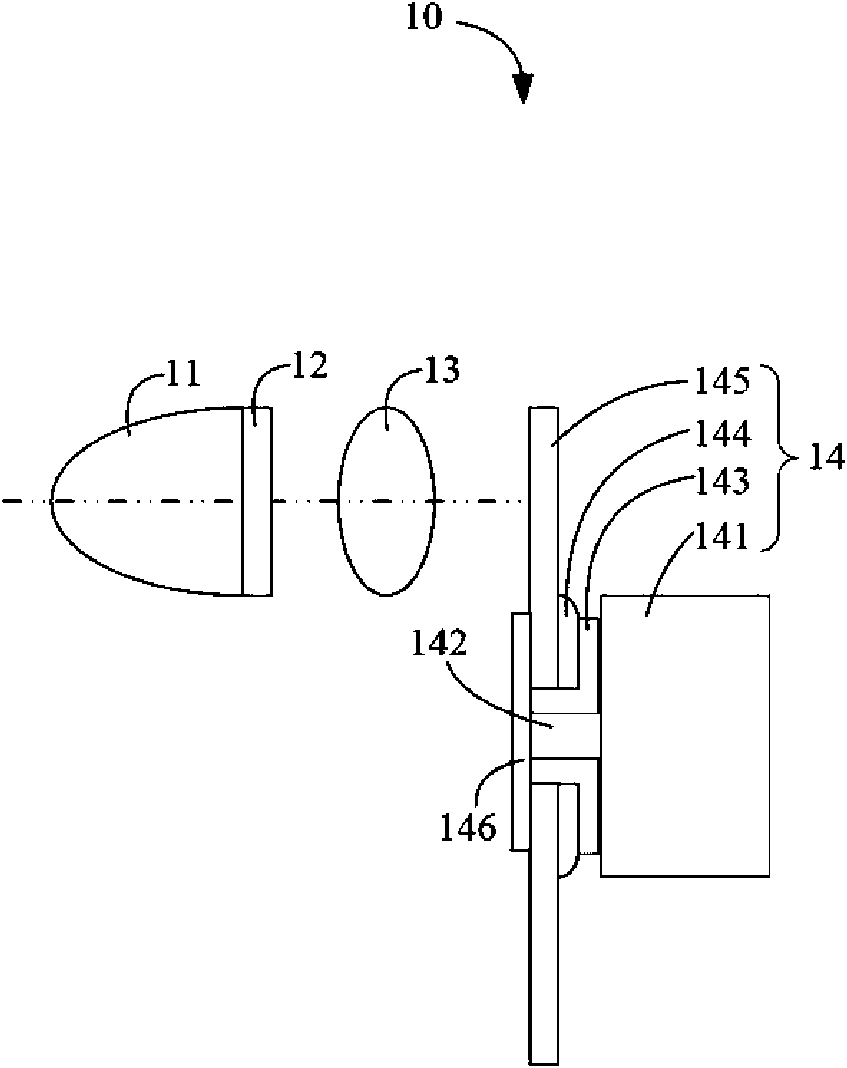

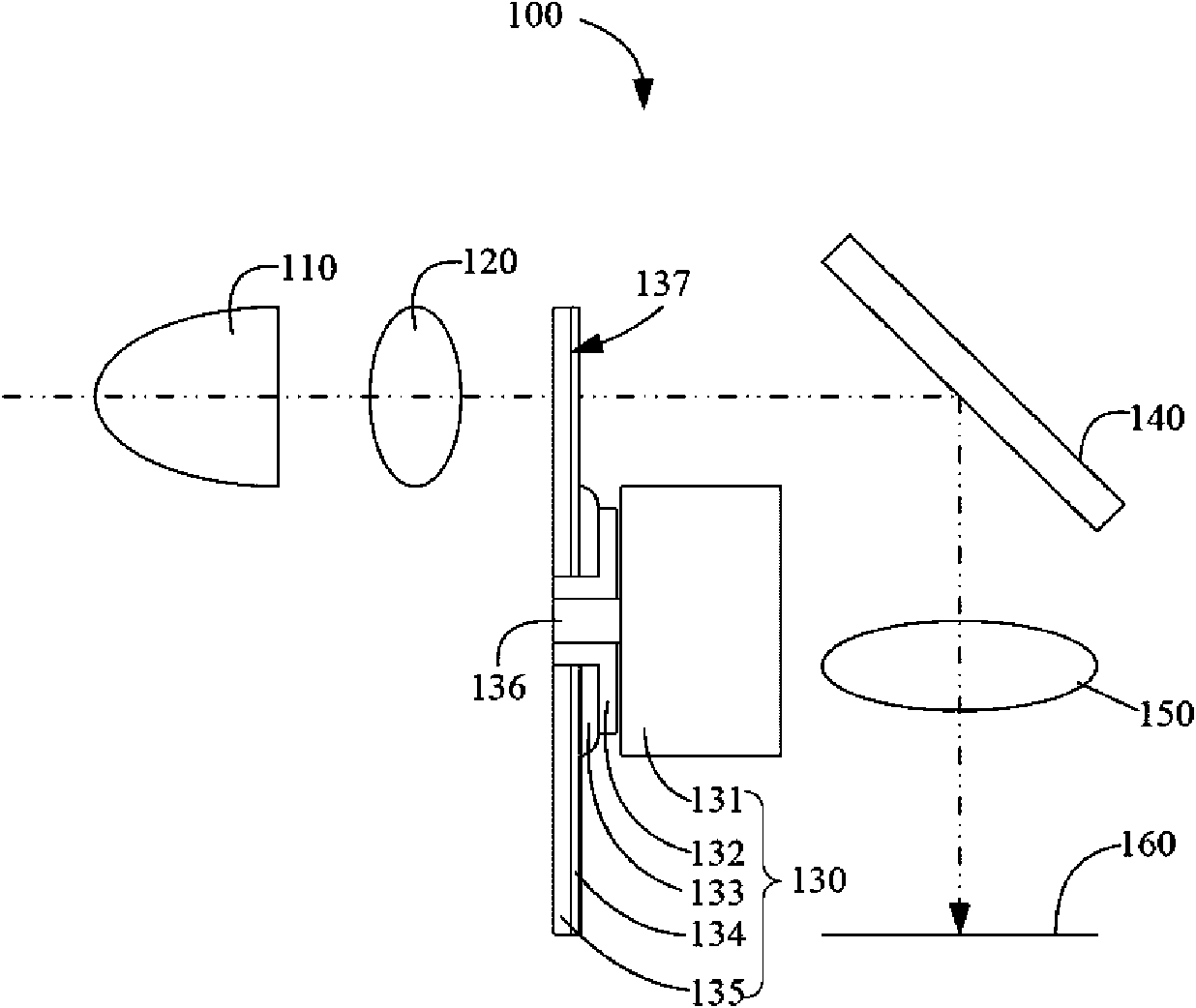

[0013] see figure 2 The digital light processing projector 100 according to the first embodiment of the present invention includes a light source 110 and a condenser lens 120 arranged along the light path of the light source 110 , a color wheel 130 , a digital micromirror chip 140 and a projection lens 150 . The color wheel 130 includes a motor 131 , a carrier 132 , curing glue 133 , a color wheel piece 134 and an ultraviolet filter 135 . The motor 131 includes a rotor 136 . The carrier 132 is fixed to the rotor 136 . The color wheel piece 134 is attached to the carrier 132 through the curing glue 133 . The ultraviolet filter 135 is an ultraviolet filter film formed on the surface 137 of the color wheel 134 opposite to the curing glue 133 .

[0014] The light source 110 can be a high-pressure mercury lamp, a metal halide lamp or a xenon lamp for generating white light. This embodiment adopts a high-pressure mercury lamp.

[0015] The condensing lens 120 is used for conde...

no. 2 approach

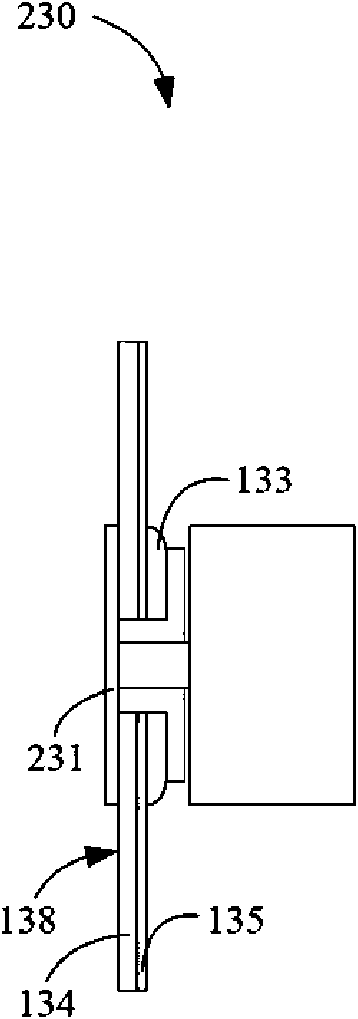

[0022] see image 3 The difference between the color wheel 230 of the second embodiment of the present invention and the color wheel 130 of the first embodiment is that the color wheel 230 of this embodiment further includes a cover sheet 231 . The cover sheet 231 is fixed on the surface 138 of the color wheel sheet 134 opposite to the ultraviolet filter 135 .

[0023] The cover sheet 231 can block all light from irradiating the cured glue 133 to increase the protection of the cured glue 133 .

no. 3 approach

[0025] see Figure 4 The difference between the color wheel 330 of the third embodiment of the present invention and the color wheel 230 of the second embodiment is that the ultraviolet filter 310 of this embodiment includes a transparent substrate 311 with the same shape as the color wheel sheet 134 and formed on a transparent An ultraviolet filter film 312 on one surface of the substrate 311 . The ultraviolet filter 310 is fixed on the surface 139 of the cover 231 opposite to the color wheel 134 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com