Beta-carotene microcapsules rich in sardine oil and its preparation method and application

A technology of carotene and sardines, applied in the field of health food

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

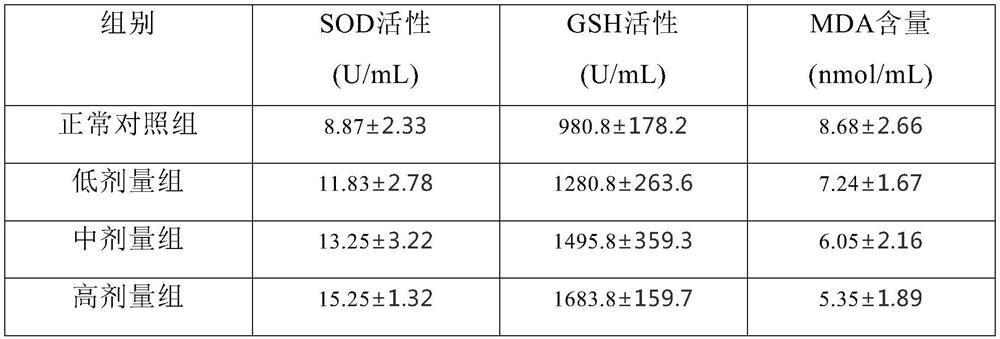

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of water phase: Add 50kg of modified starch, 15kg of chitosan, 0.05kg of trehalose, 0.05kg of sucrose, and 0.05kg of monoglyceride succinate into 260kg of water in sequence, stir while adding, mix evenly, and keep the temperature of the solution At 60°C, an aqueous phase was prepared;

[0028] (2) Oil phase preparation: 25 kg of β-carotene crystals, 2 kg of lipophilic emulsifier polysorbate and 50 kg of sardine oil were added to the oil phase kettle, stirred and dissolved at 60° C. to obtain the oil phase.

[0029] (3) Microemulsion preparation: slowly add the oil phase into the water phase, and cut while adding, wherein the rotation speed is 100,000 rpm, after cutting for 10 minutes, repeat the homogenization three times under the condition of 45Mpa to obtain a microemulsion ;

[0030] (4) Preparation of microcapsules: first lower the temperature of the microemulsion to -10°C, then place it in a freeze-drying oven at -40°C, take out the resulting solid...

Embodiment 2

[0032] (1) Water phase preparation: add 40kg of modified starch, 10kg of chitosan, 0.06kg of trehalose, 0.04kg of sucrose, and 0.08kg of monoglyceride succinate into 260kg of water in sequence, stir while adding, mix evenly, and keep the solution temperature At 70°C, an aqueous phase was prepared;

[0033] (2) Preparation of oil phase: 20 kg of β-carotene crystals, 2 kg of lipophilic emulsifier polysorbate and 60 kg of sardine oil were added to an oil phase kettle, stirred and dissolved at 50°C to obtain an oil phase.

[0034] (3) Microemulsion preparation: slowly add the oil phase into the water phase, and cut while adding, wherein the rotating speed is 120,000 revolutions / min, after shearing for 10 minutes, repeat the homogenization four times under the condition of 40Mpa, and obtain the microemulsion Lotion;

[0035] (4) Preparation of microcapsules: first lower the temperature of the microemulsion to -10°C, then place it in a freeze-drying oven at -40°C, take out the resu...

Embodiment 3

[0037] (1) Water phase preparation: Add 50kg of modified starch, 15kg of chitosan, 0.05kg of trehalose, 0.04kg of sucrose, and 0.08kg of monoglyceride succinate into 260kg of water in sequence, stir while adding, mix evenly, and keep the temperature of the solution At 70°C, an aqueous phase was prepared;

[0038] (2) Oil phase preparation: 20 kg of β-carotene crystals, 2 kg of lipophilic emulsifier polysorbate and 60 kg of sardine oil were added to the oil phase kettle, stirred and dissolved at 50°C to obtain the oil phase.

[0039] (3) Microemulsion preparation: slowly add the oil phase into the water phase, and cut while adding, wherein the rotating speed is 100,000 revolutions / min, after cutting for 10 minutes, repeat the homogenization four times under the condition of 60Mpa, and obtain the microemulsion Lotion;

[0040] (4) Preparation of microcapsules: first lower the temperature of the microemulsion to -20°C, then place it in a freeze-drying oven at -50°C, take out the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com