Lead-acid battery grid

A technology of lead-acid batteries and grids, which is applied in the direction of electrode carriers/collectors, etc., can solve the problems of low utilization rate of active materials, small contact area between grids and active materials, etc., and achieve controllable alloy composition, good mechanical properties, The effect of capacity improvement

Inactive Publication Date: 2009-12-16

张天任

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The contact area between the grid and the active material is small, and the utilization rate of the active material is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

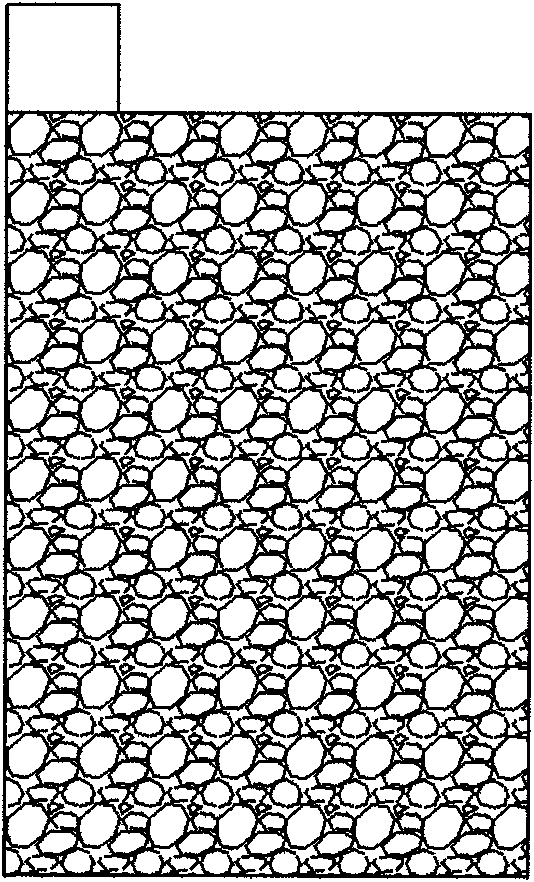

[0017] like figure 1 As shown, the grid of the present invention is a plate made of lead-based foam. Its surface is an irregular concave-convex surface, and its section in any direction is an irregular concave-convex surface (the plate is densely covered with honeycomb small pores).

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

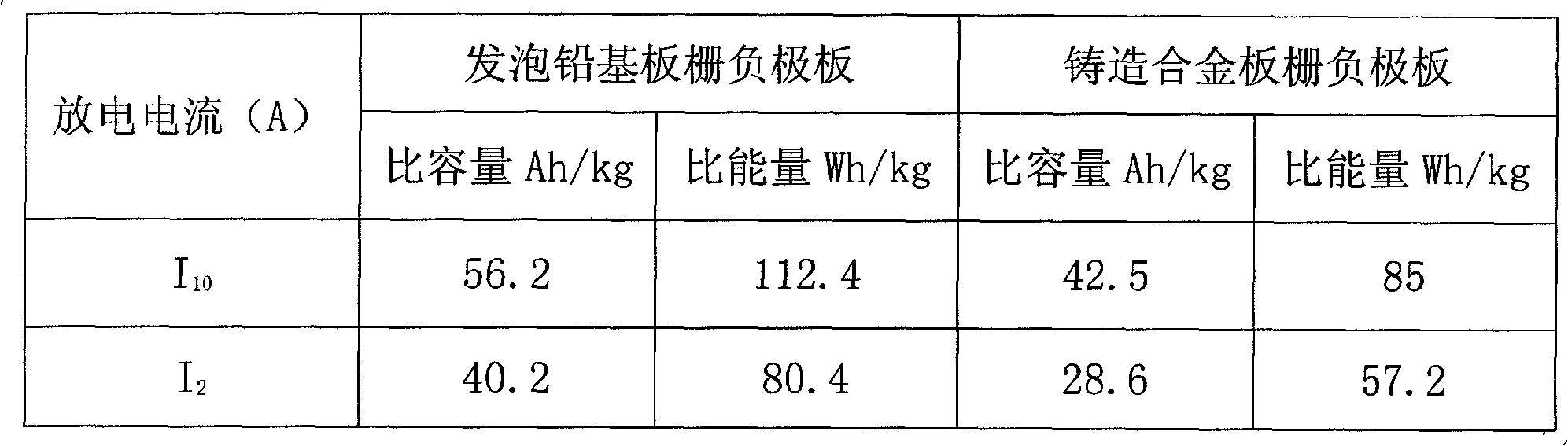

The invention discloses a lead-acid battery grid. The grid adopts a foamed lead-based board; the surface of the board and the profile in any direction of the board form irregular convex-concave faces (distributed with small honeycomb pores in the board). Compared with a casting alloy grid in the same size, the weight of the grid is reduced by 20 to 50 percent; the area of the foamed lead-based grid is 5 to 15 times of that of the casting alloy grid so as to increase the contact area of the foamed lead-based grid and active substances, reduce internal resistance and improve the utilization rate of the active substances; and the foamed lead-based grid has large negative board capacity, the capacity increases 10 to 30 percent and the specific energy increases 15 to 35 percent. The foamed lead-based grid has good mechanical performance and controllable alloy compositions, and can use pure lead, lead calcium alloy, tin-lead alloy, lead-calcium tin-aluminium alloy and rare earth alloy.

Description

Technical field: [0001] The invention relates to a lead-acid battery, in particular to a pole plate grid of the lead-acid battery. Background technique: [0002] The grid is an important part of the valve-regulated lead-acid battery, which is used to coat the active material and realize the charging and discharging function of the battery. The current grids are all made by casting, the cross-section of the ribs is triangular or trapezoidal, the junctions are at right angles, and the longitudinal and transverse ribs are evenly distributed. The contact area between the grid and the active material is small, and the utilization rate of the active material is low. Invention content: [0003] The technical problem to be solved by the present invention is to provide a lead-acid storage battery grid, which has a large contact area with the active material and a high utilization rate of the active material. [0004] The present invention is realized through the following technic...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M4/73

CPCY02E60/12Y02E60/10

Inventor 谢鸣生杨惠强任安福

Owner 张天任

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com