Weld shape design method capable of ensuring undermatching butt joint to bear load in light of strength of parent materials

A technology of butt joint and design method, which is applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of unequal, inequivalent, and low-matching butt joints with low bearing capacity compared with the base metal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

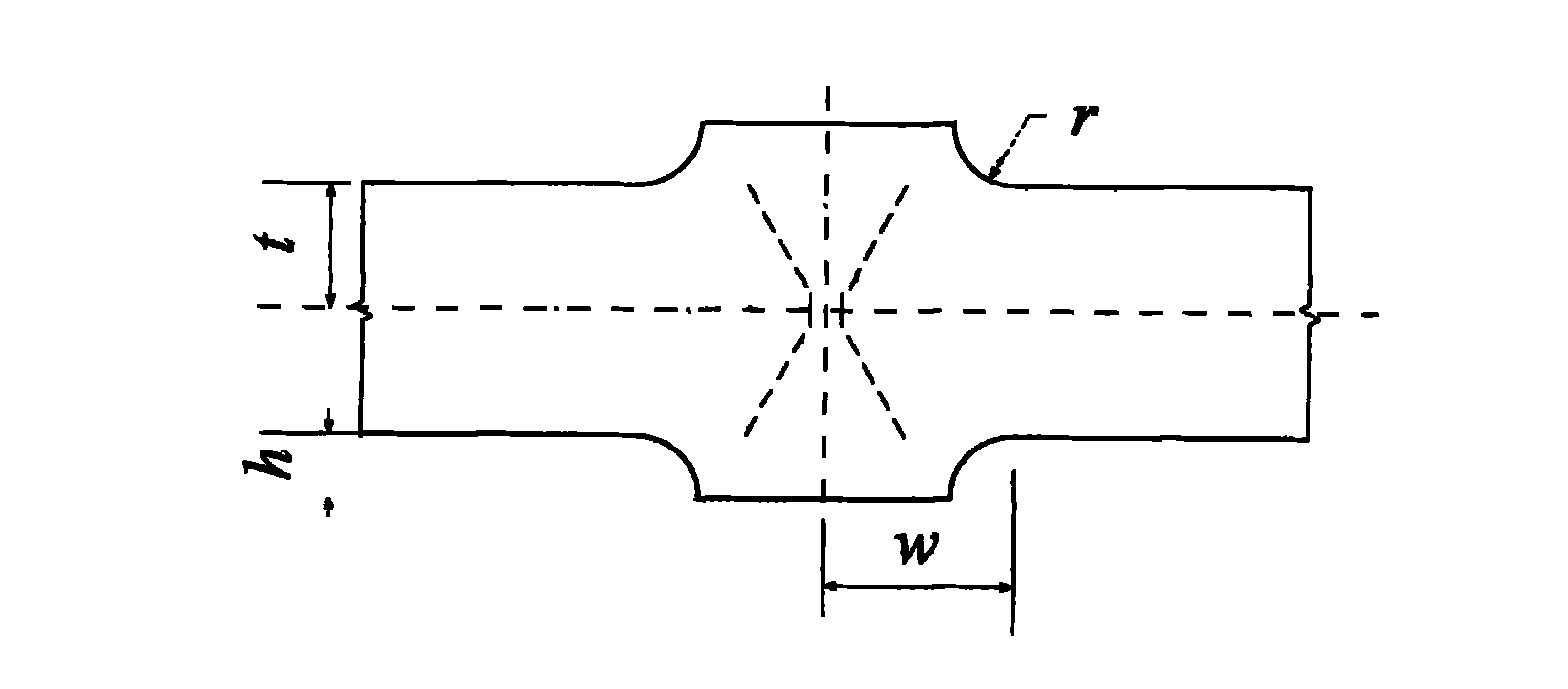

[0072] Specific implementation mode one: see figure 1 The weld shape design method described in this embodiment that can make the low-matching butt joint bear the strength of the base metal is based on the fact that the stress concentration factor of the weld root is equal to the matching ratio of the yield strength of the low-matching joint, and the stress concentration factor of the weld toe is reduced as much as possible. "Equal load"; according to the bearing characteristics, when the fatigue strength requirement of the butt joint is not very high, the shape of the weld seam of the butt joint is determined as figure 1 The shown weld shape adopts a simple circular arc curve transition between the reinforcement and the base metal; the design method of the weld shape is:

[0073] Step 1. Calculate the yield strength matching ratio μ of low-matching joints MMR (The ratio of the yield strength of the weld deposited metal to the yield strength of the base metal): design a plate...

specific Embodiment approach 2

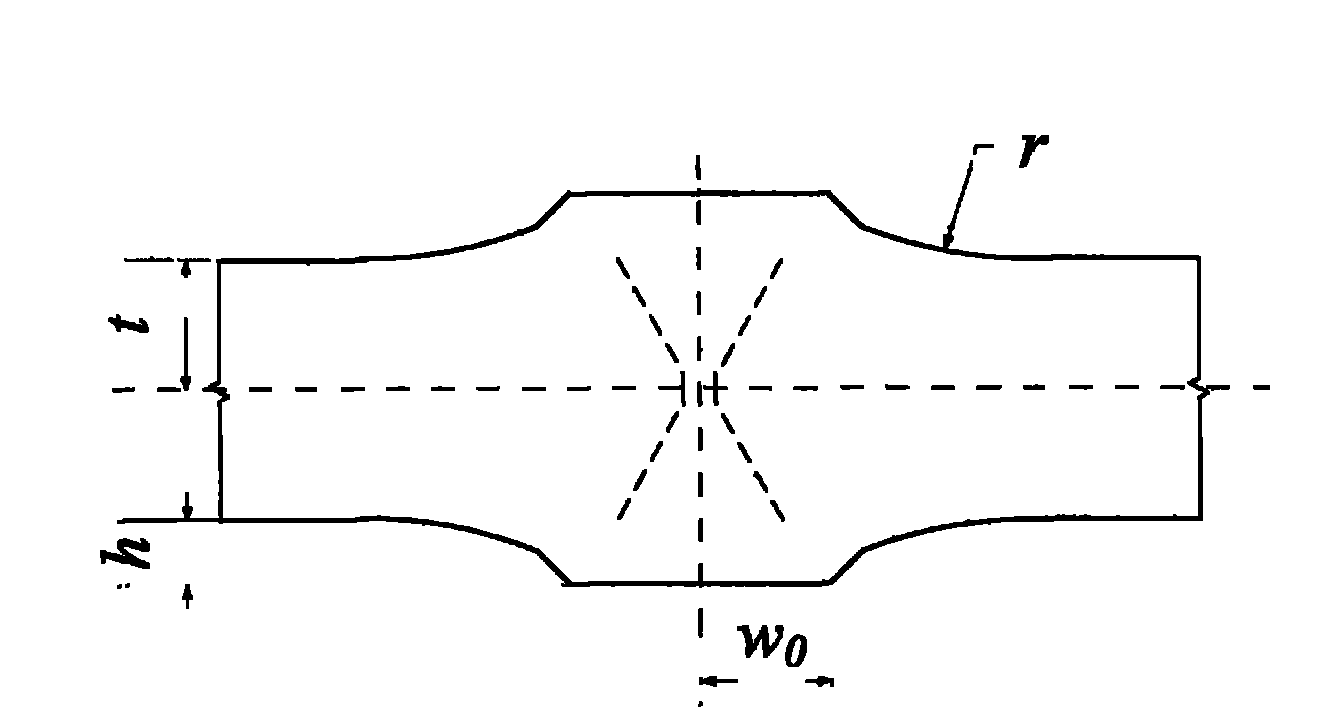

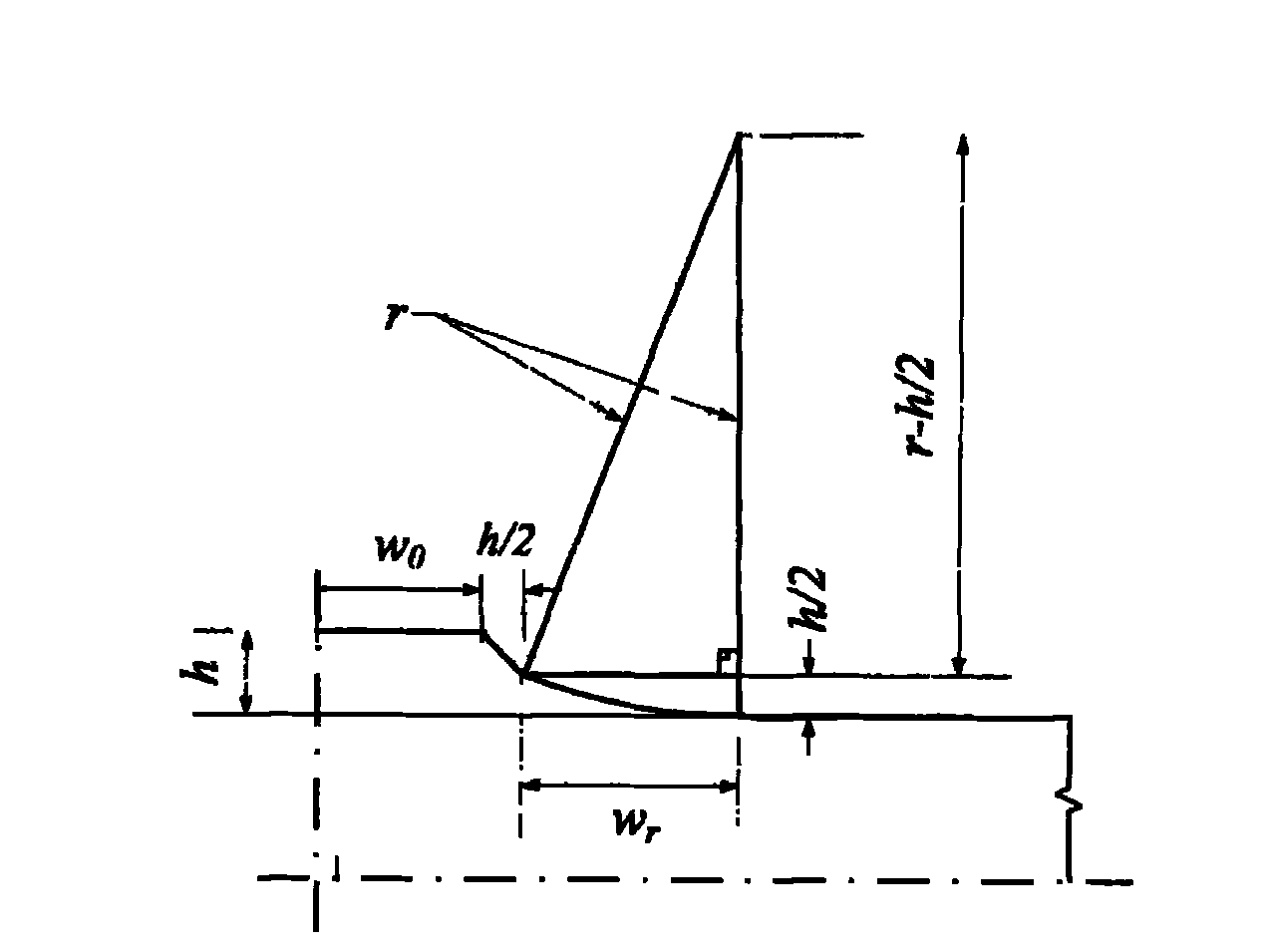

[0098] Specific implementation mode two: see figure 2 and image 3 The weld shape design method described in this embodiment that can make the low-matching butt joint bear the load according to the strength of the base metal is based on the fact that the stress concentration factor of the weld root is equal to the matching ratio of the yield strength of the low-matching joint, and the stress concentration factor of the weld toe is minimized. "Equal load"; according to the bearing characteristics, when the fatigue performance of the butt joint is very high, the shape of the weld seam of the butt joint is determined as: figure 2 The transition curve shown between the reinforcement and the base metal includes two parts: a 45° broken line and an arc curve; the weld shape design method is as follows:

[0099] Step 1. Calculate the yield strength matching ratio μ of low-matching joints MMR (The ratio of the yield strength of the weld deposited metal to the yield strength of the ...

Embodiment

[0131] Example (combined Figures 1 to 4 ):

[0132] 1. Design the plate-shaped tensile specimen, test the tensile properties of the base metal and the weld metal, and take the average value of the three specimens to obtain the yield strength matching ratio of the joint.

[0133] 2. According to the bearing characteristics, select the ideal or non-idealized weld shape scheme; according to the matching ratio of the plate thickness and the yield strength of the joint, according to the design steps of the specific embodiment 1 or the specific embodiment 2, determine the low matching "equivalent bearing" "Weld geometry parameter values for butt joints.

[0134] 3. Welding low matching butt joints, the welding sequence is as follows Figure 4 shown.

[0135] 4. Machining to obtain the weld shape of the "equal load" butt joint and its joint geometric parameter values. In the case of ensuring the designed height, the upper surface of the excess height may not be polished. For ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com