Weighing device of CAN bus elevator car

A CAN bus and weighing device technology, applied in the field of elevator control, can solve the problems of inaccurate motor torque and inverter current deviation, and achieve the effects of convenient installation and debugging, high positioning accuracy, and low data error rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

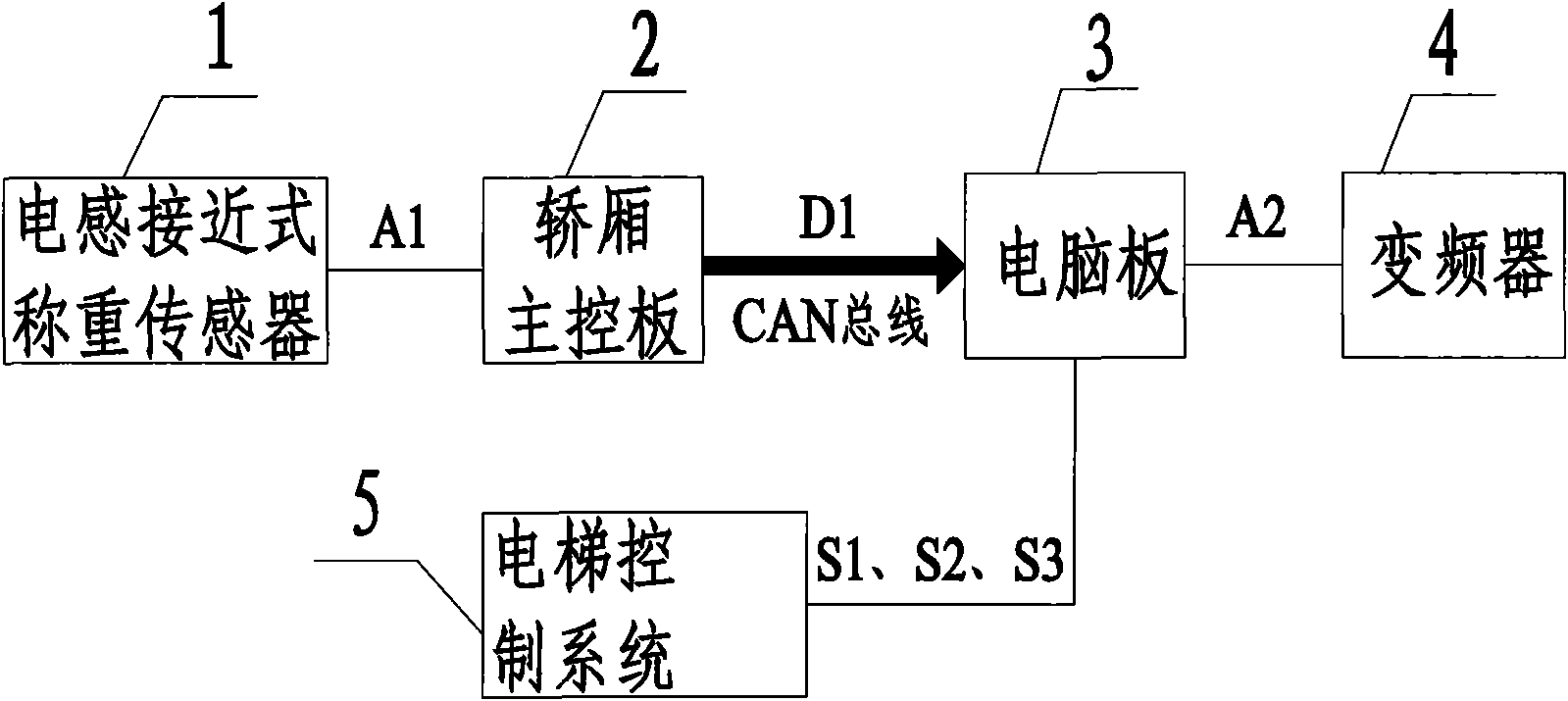

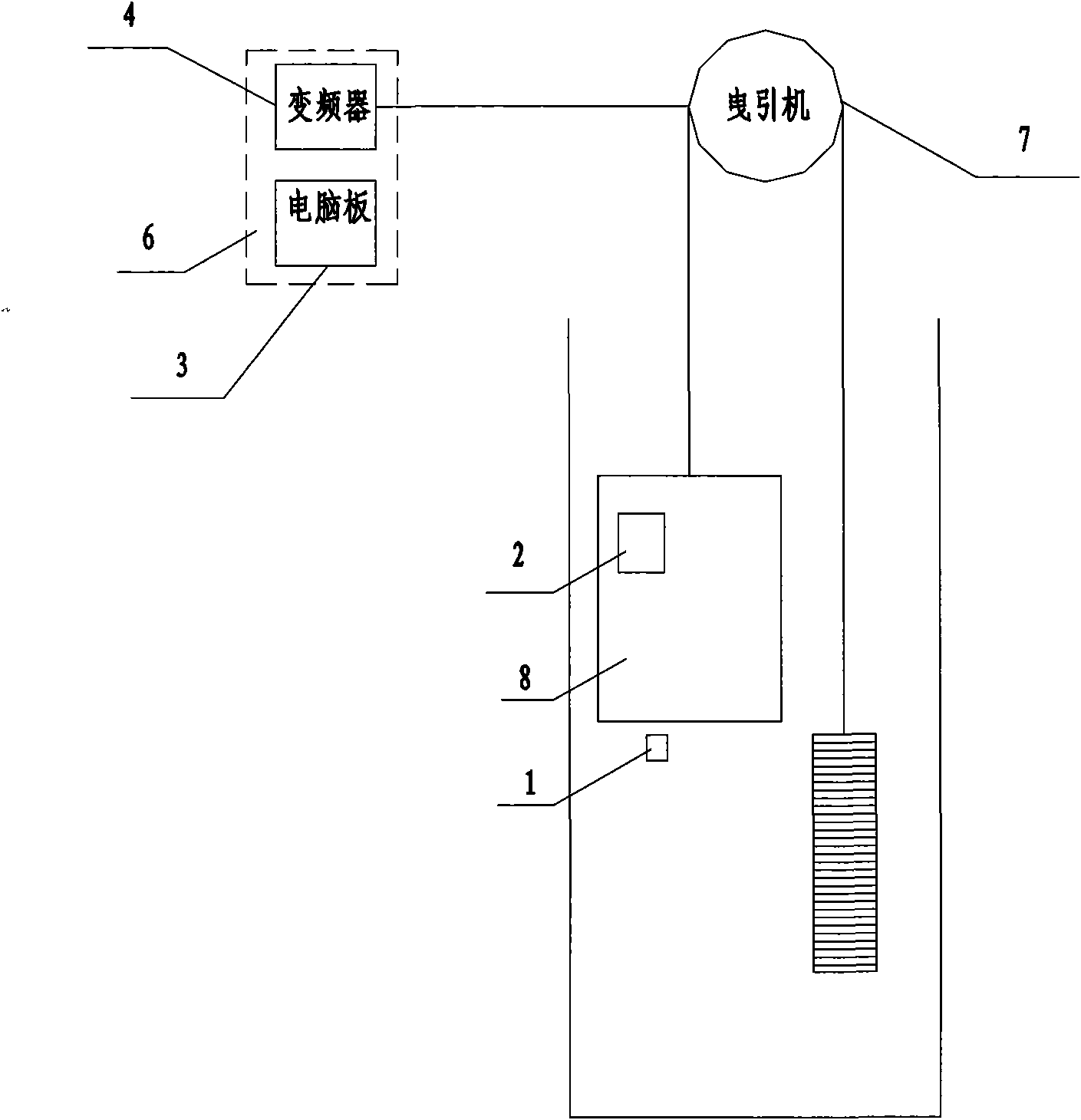

[0024] see figure 1 and figure 2 , the figure shows a CAN bus car weighing device of the present invention, including an elevator control system 5, a frequency converter 4, the frequency converter 4 is arranged in the machine room 6, and the frequency converter 4 is connected to the elevator through a traction machine 7 The car 8 is connected, and the lower part of the car 8 has a crossbeam (not shown in the figure), and also includes an inductive proximity load cell 1, a car main control board 2 and a computer board 3 that are electrically connected in sequence, wherein:

[0025] The inductive proximity load cell 1 is a non-contact elevator weighing control device, which is fixed on the beam of the elevator car 8 to measure the relative distance between the car 8 and the beam after being compressed by gravity. Output the corresponding analog voltage signal A1 to the car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com