Environment friendly release paper coated with silicon partially and preparation method thereof

A release paper, local technology, applied in chemical instruments and methods, coating, papermaking, etc., can solve problems such as low work efficiency, increase production costs, waste, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below by specific examples.

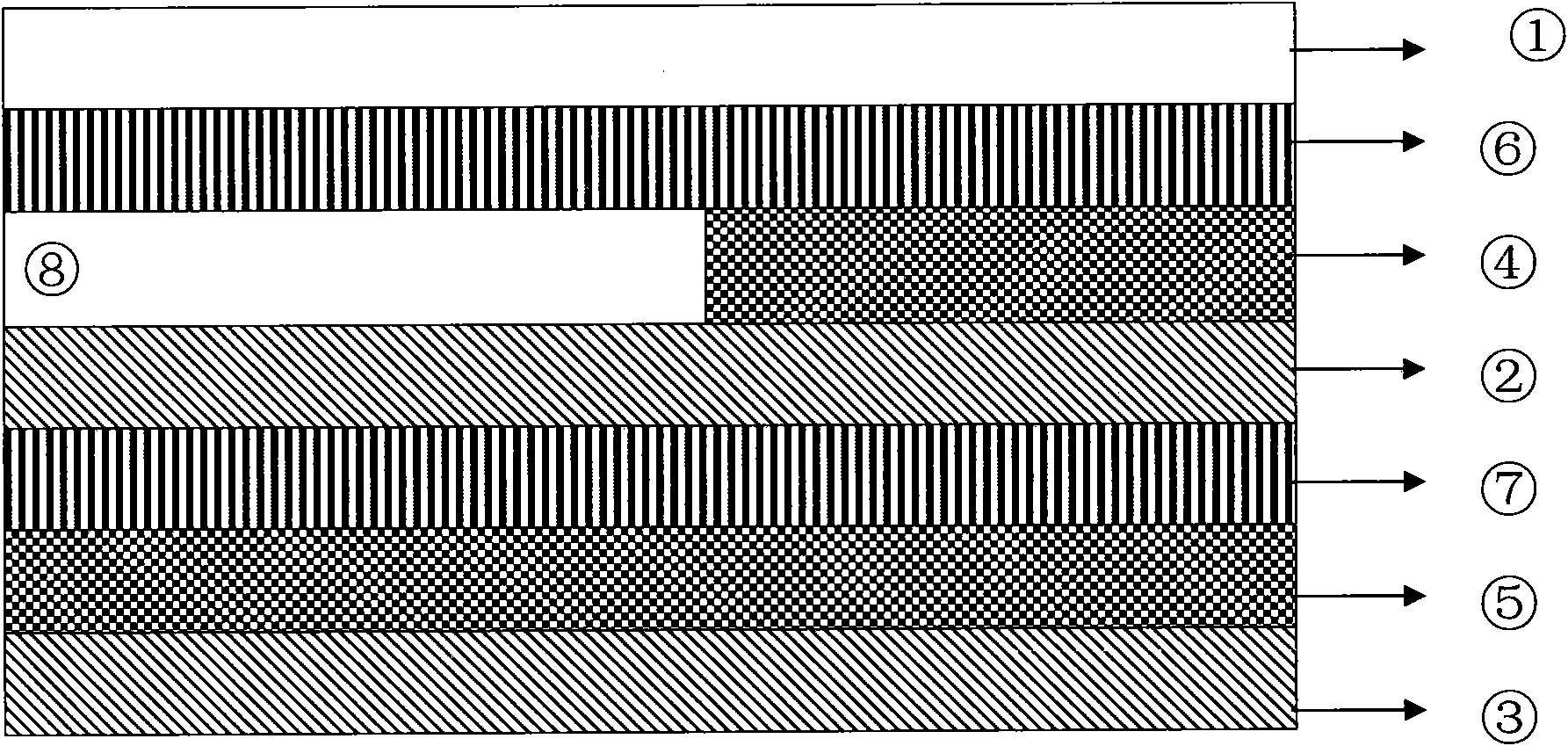

[0019] figure 1 It is a schematic diagram of the cross-sectional structure of the double-layer release paper of the present invention, which includes a glassine backing paper 1 that is fully coated with a silicone oil layer 2, a first adhesive layer 3, a release paper 4, a second adhesive layer 7 and Heat-sensitive paper surface material 8, wherein between the release paper 4 and the second layer of adhesive layer 7, there is a dyed silicone oil layer 5 for local positioning coating, and the dyed silicone oil layer 5 forms different coatings according to the needs of production. Cloth shape, the uppermost heat-sensitive paper surface material 8 can be easily torn off and then pasted on the product used according to the production process of the product used, and the dyed silicone oil layer 4 coated with local positioning below it can make the heat-sensitive paper Partially isolated and separated, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com