Check fire valve for flue

A fire damper and non-return technology, applied in the direction of control valve, safety valve, balance valve, etc., can solve the problems of not having the forced closing position of the valve plate, the effect of exhausting oil fume is worse, and threatening the life safety of residents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

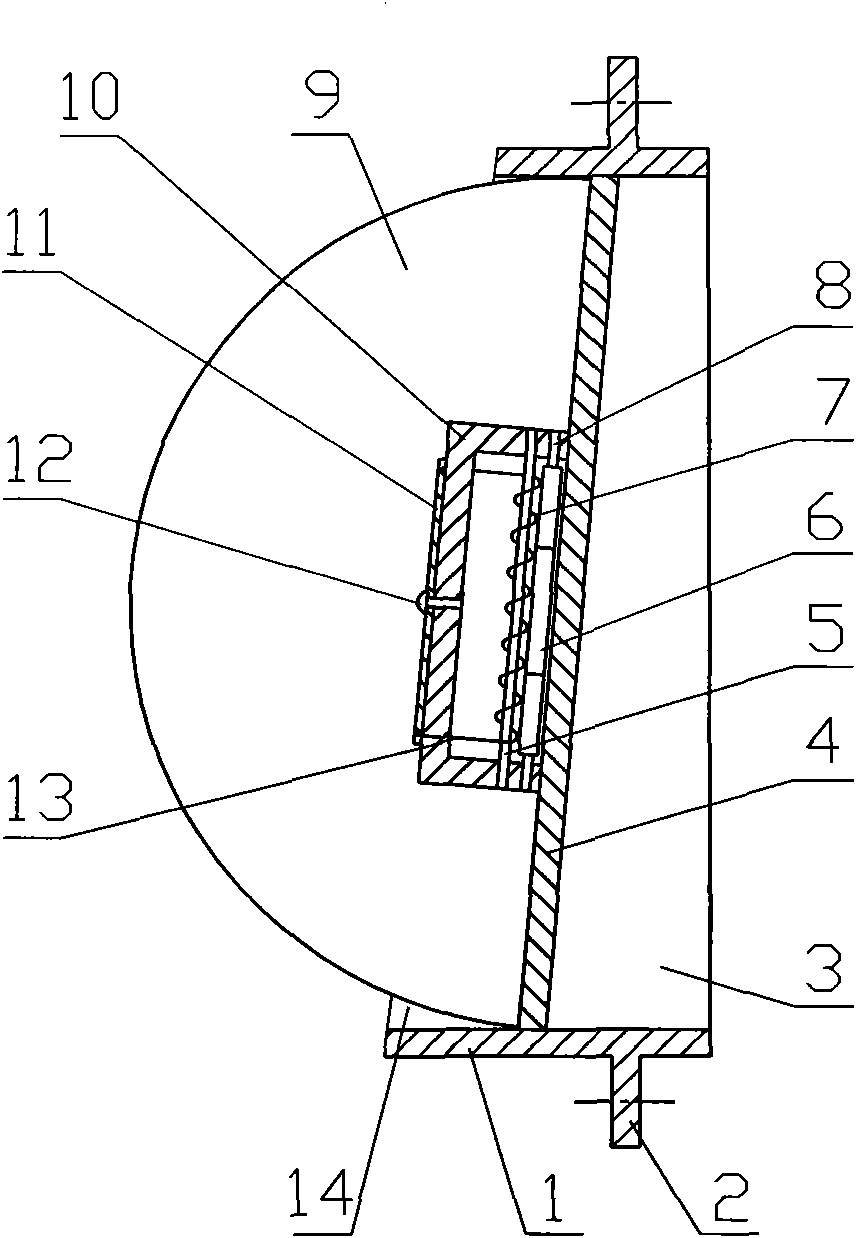

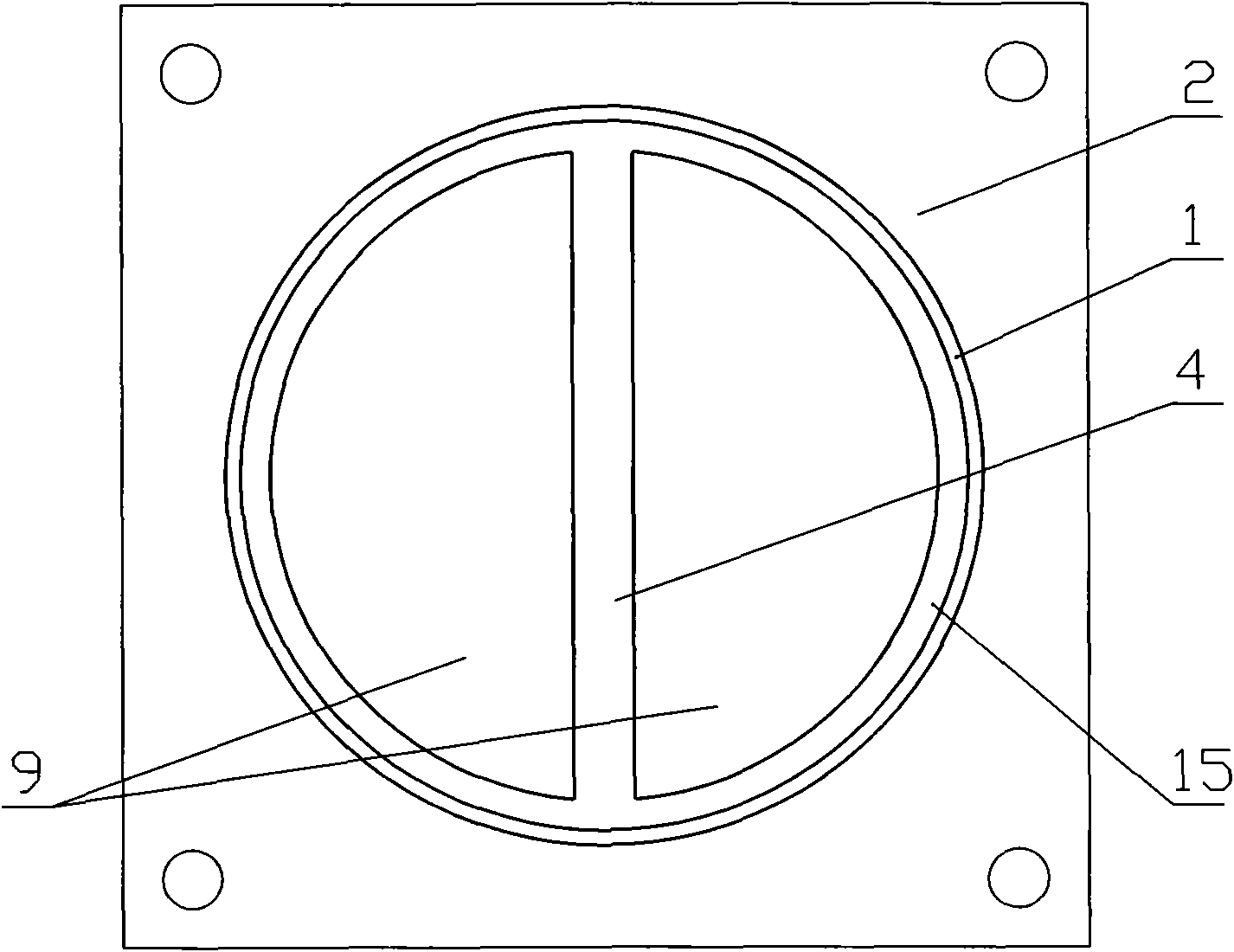

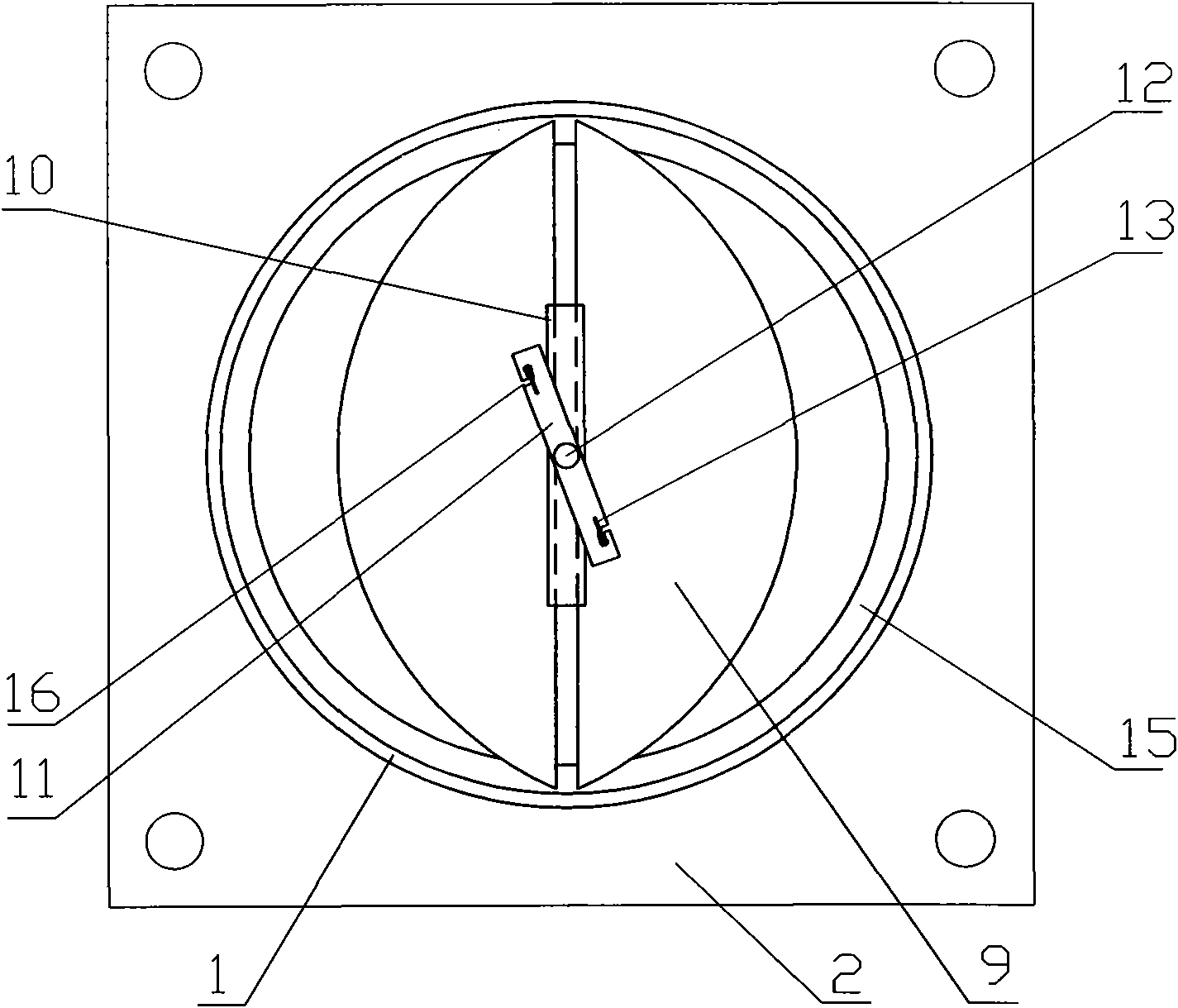

[0020] Figure 1-Figure 3 The shown flue check fire damper includes a cylindrical oil fume passage formed by the casing 1. The oil fume passage can be a variable-diameter passage. The oil fume passage has an opposite air inlet 3 and an air outlet 14 (that is, the opposite The air inlet channel and the air outlet channel), the outer wall of the housing 1 is provided with a mounting plate 2, and the end of the oil fume channel near the air inlet 3 is provided with a blocking body 15. The blocking body 15 is an annular body arranged on the inner wall of the oil fume channel. The blocking body 15 can also be a boss arranged on the inner wall of the oil fume passage or convex points arranged at annular intervals along the inner wall of the oil fume passage. In the fume passage, near the side of the air inlet 3, there is a vertically arranged connecting strip 4 that divides the air inlet 3 into two parts. The connecting strip 4 and the blocking body 15 can be integrally arranged, su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com