Hydraulic control system of steel tube clamping device in hydraulic pressure test tube machine

A clamping device and clamping hydraulic cylinder technology, applied in fluid pressure actuating devices, measuring devices, mechanical equipment, etc., can solve problems such as rupture of connecting oil pipes, accidents, heightening, etc., to ensure accuracy and improve production rhythm Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

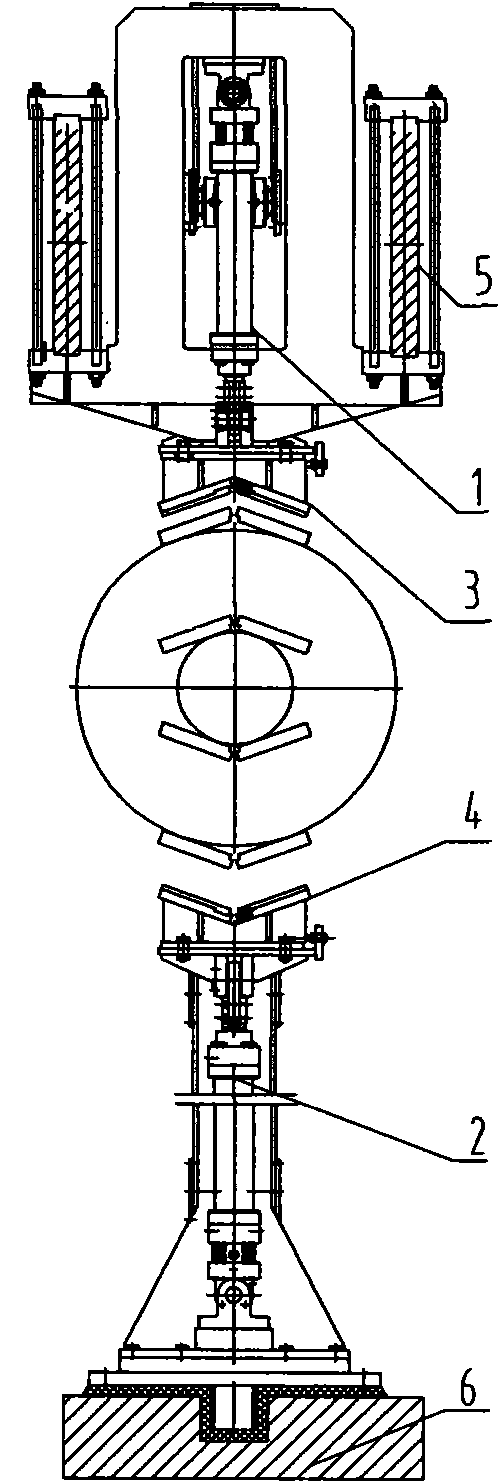

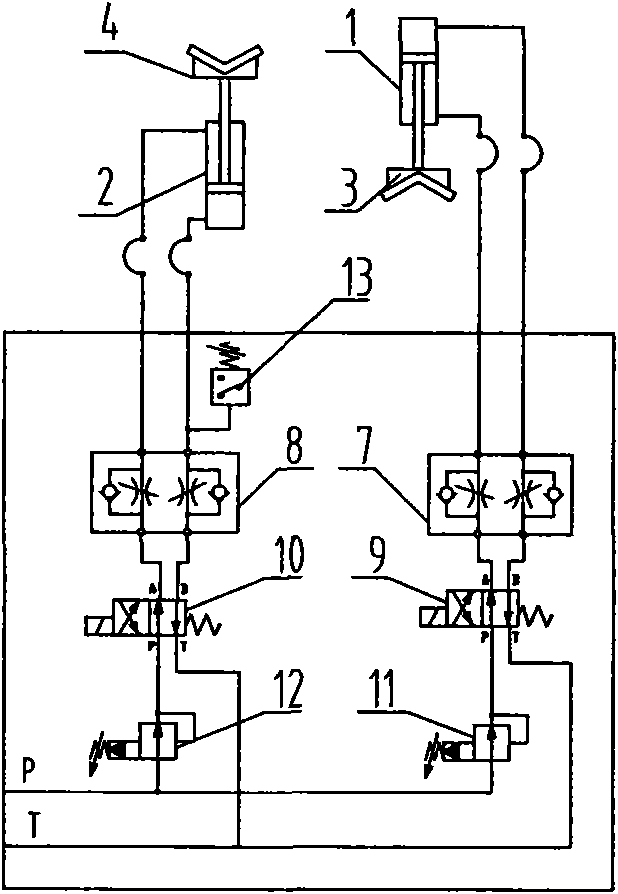

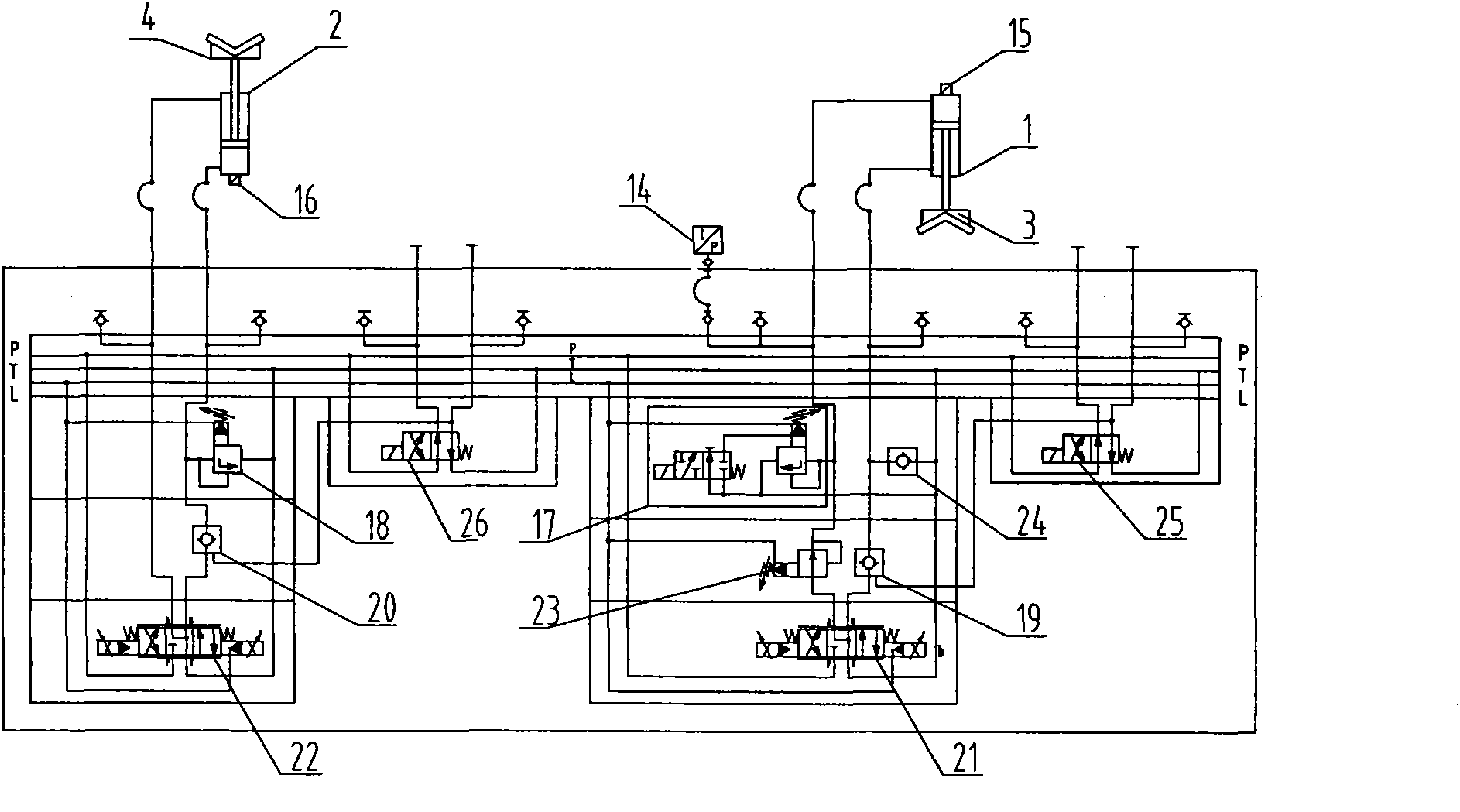

[0021] Such as image 3 As shown, a hydraulic control system of a steel pipe clamping device in a hydraulic test tube machine is mainly composed of an upper clamping hydraulic cylinder 1 and an upper clamp 3 installed on the head of its piston rod, a lower clamping hydraulic cylinder 2 and its piston The lower fixture 4 installed on the head of the rod is composed of a hydraulic control circuit formed by a conventional connection method including an electromagnetic reversing valve, a pressure reducing valve and a hydraulic oil pipe. The upper clamping hydraulic cylinder 1 is equipped with a displacement sensor 15, and is connected with a pressure sensor 14, an electromagnetic overflow valve 17, a one-way valve 24, a pressure reducing valve 23, and No. I hydraulic control one-way valve 19 and I according to a conventional connection method. No. proportional reversing valve 21, No. III electromagnetic reversing valve 25 and hydraulic oil pipe form a hydraulic control circuit; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com