Acceleration and deceleration control device and acceleration and deceleration control method

An acceleration and deceleration control, acceleration and deceleration technology, applied in the direction of digital control, program control, electrical program control, etc., can solve problems such as corner error, achieve the effect of smooth jerk curve, processing precision and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

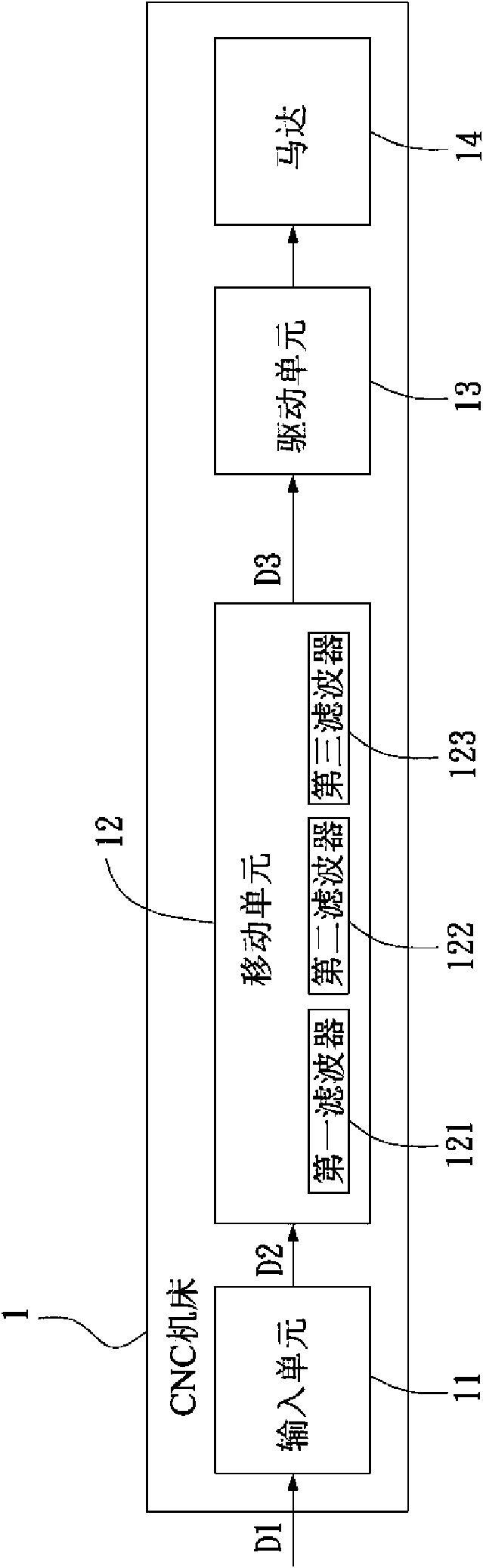

[0026] Please refer to Figure 5 As shown, the preferred embodiment of the acceleration and deceleration control device of the present invention is used for acceleration and deceleration planning of a CNC machine tool, which includes an interpolation arithmetic unit 21, a movement unit 22, a drive conversion unit 23, and an A motor 24 that drives a tool or a work platform 25.

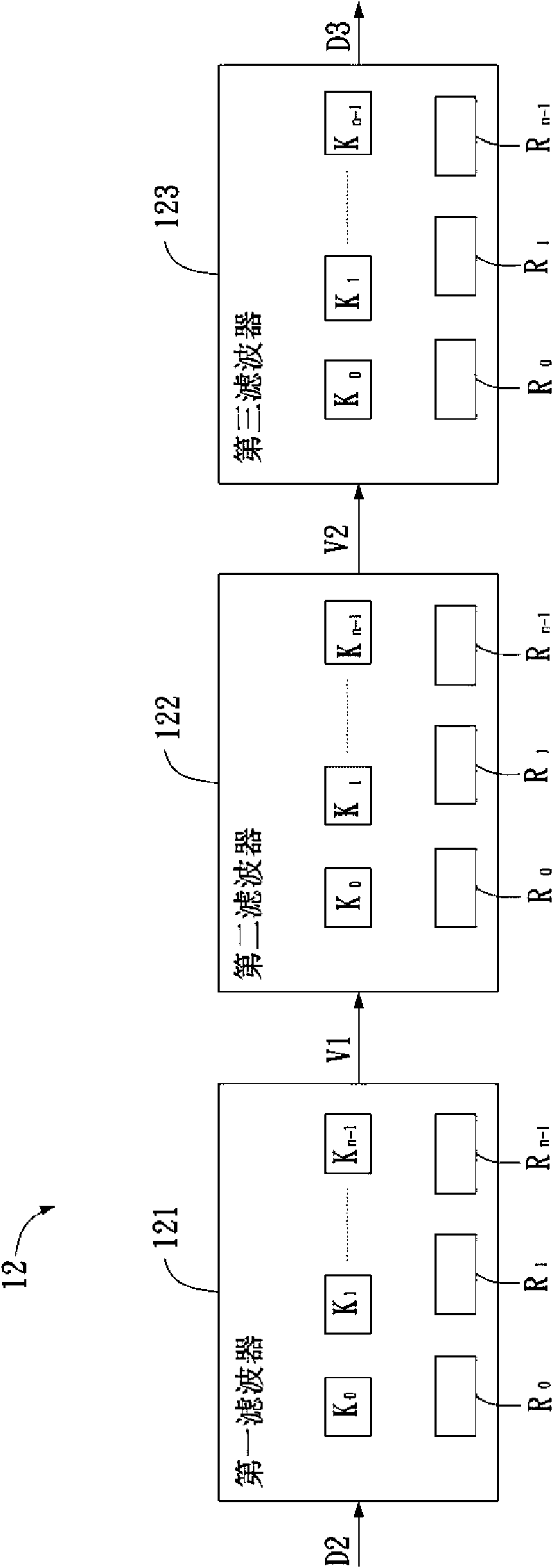

[0027] The interpolation arithmetic unit 21 is used to receive a speed command S1, and obtain a pulse speed Vx (such as Figure 7 Shown); The mobile unit 22 includes an arithmetic filter 221 to receive the pulse velocity Vx; Figure 6 As shown, the arithmetic filter 221 includes a plurality of buffers 2212, and these buffers 2212 respectively have a different weight value ω 0 , Ω 1 ...ω n-1 . The arithmetic filter 221 uses a first function to determine the pulse velocity Vx and each weight value ω 0 , Ω 1 ...ω n-1 , Calculate an acceleration and deceleration pulse V′x (such as Figure 8 Shown), these weight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com